We wanted to do a video of the fitting of the SKS-AR Mag adapter, Most people can do it with a simple Dremel & some patience. We show the stock parts & the modified parts side by side to see the difference.

Here is a pictorial version of the conversion as well:

We wanted to let you know, these Mag adapters are available on our website now, HERE. We wanted to do a SKS-AR Mag Adapter Install Guide & Pics to help everyone out. We will do a video after the weekend, but wanted to post a guide for all those who already have one to install. Here is a conversion, step by step:

First we Make sure the gun is UNLOADED! Remember the ACTS & PROVE? Remove some metal from the front of the receiver for clearance, shown is one side done, the other untouched:

Both sides done, note how the front is cut almost to the bevel:

Next, see those trigger bars? we need to shorten them to clear the new mag:

Ta Da.....

We shorten the hold open block if the bolt will not close completely:

Test fit the mag to make sure there is clearance:

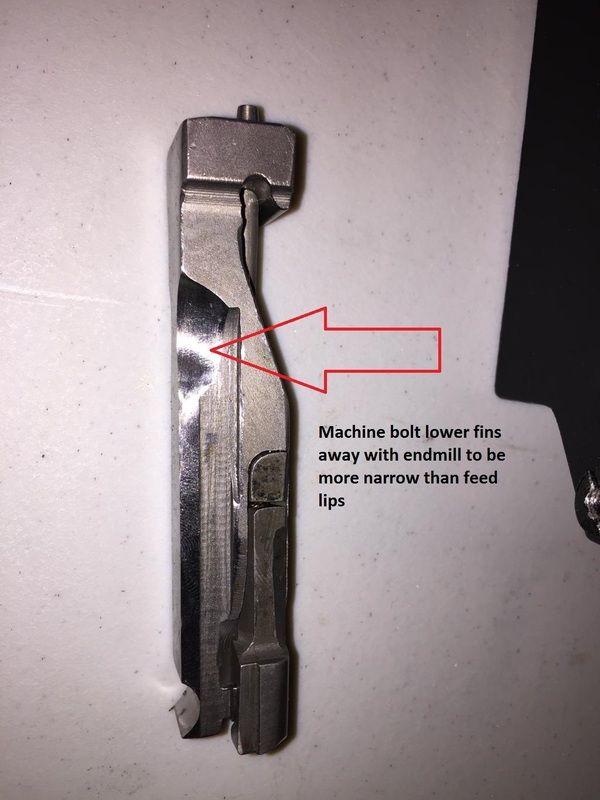

You will also need to do a bolt mod, thin up the lower bolt fins & cut them further to the rear so the bolt can close completely without touching or modifying the mag

Then trim the front silver mount to fit your gun, I mark it with a sharpie, then trim:

Install & test, the bolt hold open should work, it should drop free:

Open up your stock to clear & hit the range, or 3 gun....

NOTE, you can still use your original factory mag or any aftermarket detachable mags still after this conversion, the adapter just pops out!

|

Reply With Quote

Reply With Quote