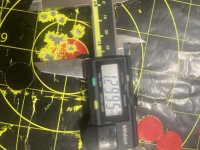

I’m all to familiar with the Raven 9 breaking firing pins. I’m currently waiting for 1 now. My 223 worked without a hiccup with factory Hornady ammo and my Handloads using new Lapua brass. At first I tried the Hornady brass reloaded and had some light strikes and ftf. At first I thought maybe the Hornady brass had deeper primer pockets causing the issue but then it is doing the same thing with the resized Lapua brass. When I never had a issue when the brass was new lt made me wonder if it was a head space issue.

Back in the good days we had AR15's, the majority of brand names made everything to spec, tolerances were tight, all my fired brass out of several different rifles were 2 thou over Sammi Min, everything got full sized and went bang and was accurate as possible.

#### we have to deal with today like these Ravens is another story, not sure I heard a real good review of them, always something breaking or out of spec.

The method to size for these has been mentioned, you got long headspace or firing pin protrusion is too short for FL sized cases. It can be dealt with, but I'd rather sell the gun.