- Location

- Oakville, ON

View attachment View attachment View attachment View attachment View attachment View attachment

View attachment View attachment View attachment View attachment View attachment View attachment  View attachment

View attachment Video sent to us by our Ukrainian clients

HTTI in Ukraine

*Updated* Includes 1x SAPI Medium(23cmx32cm) lightweight SiC plate level III+($465) or IV ($495)

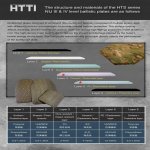

Stand Alone: Defeats ballistic threats using the plate only

Multicurve: Curvatures in both horizontal and vertical direction contours with the human body and greatly increasing mobility and comfort during long term use, especially if your sitting down like driving a vehicle.

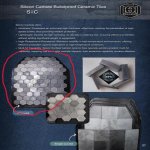

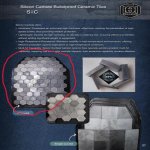

Multi hit: Our latest generation Light Weight SiC plate greatly increases multi-hit capability, meaning that even after multiple impacts their protective capability remains effective. The tile plates are much more laborious to produce and has increased manufacturing cost, but when done right it can be stronger then a monolithic design, and allowing impacts including drops to be isolated. Resulting in the highest performance in multi-hit penetration and BFD. (Level III+) 6 shots of M855 with the greatest deformation being only 29.75mm (level IV) 30-06 M2 166gr Armor Piercing at 2865fps with only 19.55mm of deformation.

Developed from the needs of our Ukrainian clients, each plate has our patented modular system built in and compatible accessories will be available for sale separately. (Trauma Pads, Emergency Plate Carrier, etc)

Serial numbers are laser-engraved on all of our bullet resistant equipment, this allows us to know the day, time, operator, and sourced material of your equipment to ensure full product history and traceability.

10 Year Warranty

(Level IV) Weight: 2.7kg / Thickness: 2.5cm

(Level III+) Weight: 2.35kg / Thickness: 2cm

We proudly manufacture our products in-house with care, allowing us to ensure quality at every step and the flexibility to adapt, make changes, and create new parts or products to match our standards. We strictly source our Kevlar from DuPont and other materials from Europe. HTTI’s entire series of bullet resistant products have passed ballistic testing at NTS Chesapeake to meet NIJ Standard and record BFD.

Attachments

Last edited: