You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.22 Headspace (or does it matter....)

- Thread starter boxhitch

- Start date

ScottMisfits

CGN Regular

Ots not going to make a 2 minute group in to a 0.25 minute group. But it may take a 0.25 group to a 0.24.

There are some benefits I have heard, but did not find in my limited sampling of trying it out. One of those benefits is consistency of ignition, which should help with your SD and ES numbers, but I didn't find that to be very significant, again, small sample size over 4 different ammo choices.

If it's way out to begin with, it may help a bit, but not a lot. Fact of the matter, most guys, at least from a practical standpoint, will never see the difference. But it might look for 25 yards paper groups.

There are some benefits I have heard, but did not find in my limited sampling of trying it out. One of those benefits is consistency of ignition, which should help with your SD and ES numbers, but I didn't find that to be very significant, again, small sample size over 4 different ammo choices.

If it's way out to begin with, it may help a bit, but not a lot. Fact of the matter, most guys, at least from a practical standpoint, will never see the difference. But it might look for 25 yards paper groups.

22 accuracy is really quite an elusive and frustrating goal and I went down the rabbit hole trying to sort rounds first by weight and then by rim thickness (closely correlates to headspace) long story short, it did seem to make a slight difference but the juice wasn't worth the squeeze. not even a little bit. what I'd like to see is companies like lapua and eley offering primed rimfire cases and weight/ shape bullets that can be seated to suit an individual rifle for max effect. apparently the propellant used in most rimfire rounds is not proprietary, it is readily available as shotgun/pistol powder. this is yet another variable that can either minimize or enlarge group size. in short, give rimfire shooters the opportunity to handload their own cartridge. might be a gateway round to get more people into handloading centerfire rounds as well.

I don't know anything that smells like Eley powder. There are kits for reloading 22 LR, but there are at least a couple of issues in doing so. Rules for various sports outlaw anything except the professionally manufactured rounds we already buy, in some cases. I'm not sure powder measuring/dispensing equipment used for reloading centrefire stuff would work all that well with powder meant for 22 LR, nor the small amounts that are used.

I don't know how we'd get bullets packaged to stay in as good of condition as we currently get in boxed loaded rounds. Seems to me if they were packaged like pellets are they'd probably get damaged before they even get to our doors. They're a lot softer than pellets. Being loaded and packaged how loaded rounds are provides them some security. Even if we swaged them ourselves I don't know that it would be all that easy to beat the machines in consistency. Dented, misshapen bullets won't fly particularly consistently. There's already a fair bit of inconsistency in shape in the rounds we already get, as evidenced by analyzing their BCs.

These surely aren't the only concerns, but they're what popped into my head before even thinking about it much. I think it's a much tougher nut to crack than reloading centrefire. It's probably an easier job to figure out a good barrel contour and length for whatever sport you're focusing on, much like benchrest shooters have done. A barrel that's meant to be tuned at 50 yards and a suitable tuner to go along with it can provide excellent results at 50 yards. If you're shooting some other sport, and perhaps aren't allowed to use tuners, you can still figure out a contour and length that is a good compromise for the requirements. I'd wager you'll get much better results doing that than reloading 22 LR, if you're even allowed to do so.

It's not easy or cheap to figure out what a good contour and length are for a given distance, but it is a solvable problem. And if you have to shoot at more than one distance then you find the best compromise on distance to minimize the overall error, kind of like a lot of people do for silhouette and ammo lot testing at 77 m. Find what shoots best there and you minimize the error at 40 m, 60 m, and 100 m, overall. It gets tougher if you have larger distance differences to contend with, seeing as how all barrels shoot best at one distance. Gotta find the best compromise for whatever it is you're shooting.

I don't know how we'd get bullets packaged to stay in as good of condition as we currently get in boxed loaded rounds. Seems to me if they were packaged like pellets are they'd probably get damaged before they even get to our doors. They're a lot softer than pellets. Being loaded and packaged how loaded rounds are provides them some security. Even if we swaged them ourselves I don't know that it would be all that easy to beat the machines in consistency. Dented, misshapen bullets won't fly particularly consistently. There's already a fair bit of inconsistency in shape in the rounds we already get, as evidenced by analyzing their BCs.

These surely aren't the only concerns, but they're what popped into my head before even thinking about it much. I think it's a much tougher nut to crack than reloading centrefire. It's probably an easier job to figure out a good barrel contour and length for whatever sport you're focusing on, much like benchrest shooters have done. A barrel that's meant to be tuned at 50 yards and a suitable tuner to go along with it can provide excellent results at 50 yards. If you're shooting some other sport, and perhaps aren't allowed to use tuners, you can still figure out a contour and length that is a good compromise for the requirements. I'd wager you'll get much better results doing that than reloading 22 LR, if you're even allowed to do so.

It's not easy or cheap to figure out what a good contour and length are for a given distance, but it is a solvable problem. And if you have to shoot at more than one distance then you find the best compromise on distance to minimize the overall error, kind of like a lot of people do for silhouette and ammo lot testing at 77 m. Find what shoots best there and you minimize the error at 40 m, 60 m, and 100 m, overall. It gets tougher if you have larger distance differences to contend with, seeing as how all barrels shoot best at one distance. Gotta find the best compromise for whatever it is you're shooting.

I'll try to provide point by point clarification and rebuttal of your post without having this thread degenerate into a poo flinging free for all. I am aware of the existence of 22 LR reloading kits but they have a major flaw, the lack of a uniform priming compound and the ability to spin it into the rim. apparently Vihta Vuori manufactures propellants for pistol/shotgun use, and for rimfire cartridges, it is 3N37. the equipment used to dispense and weigh propellants for centerfire cartridges is absolutely precise enough for use in reloading rimfire cartridges. let us consider rimfire case capacity is about 1.5 grains max, every handloader has a scale that will measure down to .1 of a grain and super precise electronic scales can measure down to .01 of a grain. now on to the bullet. some reloaders also cast their own bullets, and they can formulate lead alloys which are best suited to the barrel's rifling lands and grooves. molds can be custom machined for optimal bullet weight/ ogive/crimp groove/ base design for short or long range. at present factory 22 lr bullets are made of pure lead and the bullets are limited to only a few different designs. having custom bullets either swaged or cast and shipped to stores and shops wouldn't be an issue, full on hollow base wadcutter bullets of pure lead are sold every day. lead is soft but it isn't butter soft, they can be shipped. air rifle pellets with hollow skirts are a good example, they are also made of pure lead and they are shipped everywhere. having said that, this is where the bullet caster can produce superior bullets because of the quality control they can exercise over each individual bullet. an almost infinite array of alloy and lubricant plus the possibility of a powdercoat application instead of traditional lube.I don't know anything that smells like Eley powder. There are kits for reloading 22 LR, but there are at least a couple of issues in doing so. Rules for various sports outlaw anything except the professionally manufactured rounds we already buy, in some cases. I'm not sure powder measuring/dispensing equipment used for reloading centrefire stuff would work all that well with powder meant for 22 LR, nor the small amounts that are used.

I don't know how we'd get bullets packaged to stay in as good of condition as we currently get in boxed loaded rounds. Seems to me if they were packaged like pellets are they'd probably get damaged before they even get to our doors. They're a lot softer than pellets. Being loaded and packaged how loaded rounds are provides them some security. Even if we swaged them ourselves I don't know that it would be all that easy to beat the machines in consistency. Dented, misshapen bullets won't fly particularly consistently. There's already a fair bit of inconsistency in shape in the rounds we already get, as evidenced by analyzing their BCs.

These surely aren't the only concerns, but they're what popped into my head before even thinking about it much. I think it's a much tougher nut to crack than reloading centrefire. It's probably an easier job to figure out a good barrel contour and length for whatever sport you're focusing on, much like benchrest shooters have done. A barrel that's meant to be tuned at 50 yards and a suitable tuner to go along with it can provide excellent results at 50 yards. If you're shooting some other sport, and perhaps aren't allowed to use tuners, you can still figure out a contour and length that is a good compromise for the requirements. I'd wager you'll get much better results doing that than reloading 22 LR, if you're even allowed to do so.

It's not easy or cheap to figure out what a good contour and length are for a given distance, but it is a solvable problem. And if you have to shoot at more than one distance then you find the best compromise on distance to minimize the overall error, kind of like a lot of people do for silhouette and ammo lot testing at 77 m. Find what shoots best there and you minimize the error at 40 m, 60 m, and 100 m, overall. It gets tougher if you have larger distance differences to contend with, seeing as how all barrels shoot best at one distance. Gotta find the best compromise for whatever it is you're shooting.

Bullets for .22LR are not made of "pure lead" because it's too soft. The bullets are an alloy that includes antimony.at present factory 22 lr bullets are made of pure lead

Just a few years ago reloading .22LR ammo was seen as a solution to performance problems. Cutting Edge Bullets produced a few different monolithic 22LR bullets and a kit to reload them in supplied pre-primed casings. They were not a big success. And the cost rivalled that of some of the most expensive .22LR match ammos.

This is one of those claims for which there's no support or evidence. Who believes this kind of stuff?all barrels shoot best at one distance

Regarding headspace, as Bill Calfee has said (in many places including the source linked by Shorty above) so long as it's safe and ignition is good it's not critical for accuracy. All match ammo is made to meet CIP specifications, including Eley. CIP specs call for 1.09mm (0.043").

If accuracy performance is not as good as desired, rather than fiddling with headspace shooters would be better off using better ammo (and/or a better rifle).

Grab a 22 LR round of each brand that you have handy and pull a bullet. Take a look at the powder and compare it to any powder you've seen used for centrefire reloading. All the 22 LR powder I've seen is very fine compared to stuff I've seen for centrefire. As for pellets, there's a reason I mentioned it. I've shot enough air rifle to know that a pretty fair fraction of the pellets I ever got from any brand had been misshapen during shipping. All 22 LR bullets are swaged from lead wire. No manufacturer is casting bullets.I'll try to provide point by point clarification and rebuttal of your post without having this thread degenerate into a poo flinging free for all. I am aware of the existence of 22 LR reloading kits but they have a major flaw, the lack of a uniform priming compound and the ability to spin it into the rim. apparently Vihta Vuori manufactures propellants for pistol/shotgun use, and for rimfire cartridges, it is 3N37. the equipment used to dispense and weigh propellants for centerfire cartridges is absolutely precise enough for use in reloading rimfire cartridges. let us consider rimfire case capacity is about 1.5 grains max, every handloader has a scale that will measure down to .1 of a grain and super precise electronic scales can measure down to .01 of a grain. now on to the bullet. some reloaders also cast their own bullets, and they can formulate lead alloys which are best suited to the barrel's rifling lands and grooves. molds can be custom machined for optimal bullet weight/ ogive/crimp groove/ base design for short or long range. at present factory 22 lr bullets are made of pure lead and the bullets are limited to only a few different designs. having custom bullets either swaged or cast and shipped to stores and shops wouldn't be an issue, full on hollow base wadcutter bullets of pure lead are sold every day. lead is soft but it isn't butter soft, they can be shipped. air rifle pellets with hollow skirts are a good example, they are also made of pure lead and they are shipped everywhere. having said that, this is where the bullet caster can produce superior bullets because of the quality control they can exercise over each individual bullet. an almost infinite array of alloy and lubricant plus the possibility of a powdercoat application instead of traditional lube.

Every single rifle shooter that's ever used a tuner and understood what it is doing has seen the evidence. Science-minded people believe the evidence. Here's a project for you, should you care to take it on, and perhaps learn something in the process. Take one rifle and shoot 5- or 10-round groups using a whole box of 50 at one distance to get some half-decent numbers. Do this in 10-yard increments from as close as is practical at your range out to 100 yards, or further. If you can start at 10 yards, perfect! Crunch it all into one day or spread it out over a long period of time by just doing one distance per visit among all your other regular shooting. Set aside enough of the same ammo to complete it if you spread it out over time, so you have data from all the same lot number. Whenever you have 50 shots at each distance to compare you will be in for a surprise. Try it again with another rifle that has a different barrel contour and length and you'll be in for another surprise. Don't forget to convert to MOA to compare.This is one of those claims for which there's no support or evidence. Who believes this kind of stuff?

when I was sorting by rim thickness the most expensive rimfire ammo such as eley tenex was the most uniform but QC still let a few through at .044 and down to .042. the cheap rimfire stuff had variance from .047 to .038. now I would like to make an observation regarding barrel tuners. in order to make the tuner work well, the bullet velocity must be as uniform as possible. it doesn't matter if it is fast or slow, just that all rounds have a very low extreme spread. this may or may not be a critical factor with a rimfire bullet with a relatively slow barrel time. if the extreme spread is quite high the barrel tuner is not as effective as it could otherwise be.Bullets for .22LR are not made of "pure lead" because it's too soft. The bullets are an alloy that includes antimony.

Just a few years ago reloading .22LR ammo was seen as a solution to performance problems. Cutting Edge Bullets produced a few different monolithic 22LR bullets and a kit to reload them in supplied pre-primed casings. They were not a big success. And the cost rivalled that of some of the most expensive .22LR match ammos.

This is one of those claims for which there's no support or evidence. Who believes this kind of stuff?

Regarding headspace, as Bill Calfee has said (in many places including the source linked by Shorty above) so long as it's safe and ignition is good it's not critical for accuracy. All match ammo is made to meet CIP specifications, including Eley. CIP specs call for 1.09mm (0.043").

If accuracy performance is not as good as desired, rather than fiddling with headspace shooters would be better off using better ammo (and/or a better rifle).

ps: if rimfire bullets contain antimony and/or tin it is precious little because of the low velocity of the little bullet, plus these elements are much more expensive than raw lead (bhn 5/6). it is easy to scratch a 22 bullet with a fingernail. I performed a lead hardness test on 2 different brands of ammo, one is Eley Tenex and the other is SK Standard Plus. the Eley tested at 6 BHN, and the SK tested 7. wheelweight alloy is around 11, and linotype is about 21. wheelweight alloy resists a fingernail quite well, and linotype cannot be marked with a fingernail at all. just for the record, I'll make a statement that getting the greatest accuracy from a centerfire rifle one must handload and this is why I believe the same must be true for rimfire as well.

pps: bill calfee is spot on with his observation on headspace, but notice that the most accurate rimfire rifles have tight chambers. the only other variable is the amount of "jam" the bullet has into the rifling. this may be why headspace is a moot point. ideally, the bullet should be jammed just enough for perfect bore alignment while the rim is solidly against the barrel to get consistent uniform ignition. all of these factors is why rimfire ammo cannot be one size fits all and ammo should be tailored to each rimfire rifle, just like centerfire rifles. on the flip side I don't think many people would spend the time developing the most accurate rimfire ammo on a round by round basis like is commonly done with centerfire rounds.

great discussion.

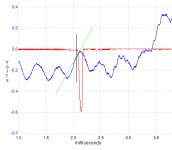

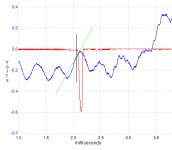

Well, the purpose of a barrel tuner is to make the barrel behave such that the barrel itself is adjusting for the differences in muzzle velocity, when properly tuned. You make it so that the muzzle rises during the bullet exit period, and does so such that the angle of departure is adjusted at a rate just quickly enough to compensate for the MV difference. Slower bullets need a higher launch angle to hit the same spot as faster bullets. The green line being the theoretical ideal slope for muzzle velocity vs. launch angle at 50 metres, and the blue line being the actual barrel measurement for the tuned barrel in question during firing.

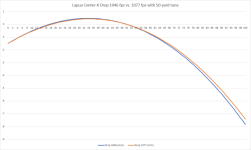

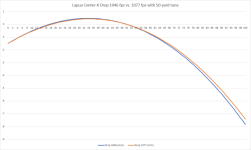

The vertical black line being the point in time when the bullet exited the muzzle for that particular shot. As slower shots take longer to exit, the muzzle rises by enough angle to compensate for the difference in flight characteristics. (Source clickable link here.) As he states in that linked article, for 50 m the required muzzle rise rate is ~6 MOA/millisecond, which is what that green line represents. Bullets exiting during a muzzle rise result in less vertical on target due to MV differences. Bullets exiting during a muzzle fall result in more vertical on target due to MV differences. The trick is to get it rising, and rising at just the right rate for a given distance. As shown here in a 50-yard example, the slower shot is on a higher arc than the fast shot right up until they both go through the same hole at 50 yards. After which, the slower shot drops further and further below the faster shot as you go further and further out.

Even without a tuner, the same thing happens. You just give up control over where the ideal distance is, and leave that up to the barrel contour and length and the barrel's resulting behaviour. A tuner lets you gain some control over the ideal distance by gaining some control over the barrel's behaviour. A tuner and a barrel are a matched set. You need a barrel length and contour that moves slightly too fast for your target distance, and you need a tuner matched to that barrel behaviour that allows you to slow the barrel down just enough to get into the sweet spot. You can't just take any random barrel contour and length and any random tuner and get the desired results at any distance you wish. It is a physics problem with very specific variables that need to be chosen with a particular goal in mind. You can focus on getting the absolute best results possible at one particular distance, such as in a benchrest rifle that's always shot at 50 yards, or you can compromise on some medium distance that will still give you good results at shorter and longer distances. But you still need to choose a region that you want to work in. No barrel shoots good at all distances. The physics of the problem make that an impossibility. The barrel vibrates a certain way in response to firing. And the behaviour of those vibrations in relation to muzzle exit timing dictates how it will shoot. In this second image the system is tuned to shoot best at 50 yards. But each bare barrel contour and length will have its own ideal distance to shoot at. The distance at which those two shots will meet each other changes based on that.

The vertical black line being the point in time when the bullet exited the muzzle for that particular shot. As slower shots take longer to exit, the muzzle rises by enough angle to compensate for the difference in flight characteristics. (Source clickable link here.) As he states in that linked article, for 50 m the required muzzle rise rate is ~6 MOA/millisecond, which is what that green line represents. Bullets exiting during a muzzle rise result in less vertical on target due to MV differences. Bullets exiting during a muzzle fall result in more vertical on target due to MV differences. The trick is to get it rising, and rising at just the right rate for a given distance. As shown here in a 50-yard example, the slower shot is on a higher arc than the fast shot right up until they both go through the same hole at 50 yards. After which, the slower shot drops further and further below the faster shot as you go further and further out.

Even without a tuner, the same thing happens. You just give up control over where the ideal distance is, and leave that up to the barrel contour and length and the barrel's resulting behaviour. A tuner lets you gain some control over the ideal distance by gaining some control over the barrel's behaviour. A tuner and a barrel are a matched set. You need a barrel length and contour that moves slightly too fast for your target distance, and you need a tuner matched to that barrel behaviour that allows you to slow the barrel down just enough to get into the sweet spot. You can't just take any random barrel contour and length and any random tuner and get the desired results at any distance you wish. It is a physics problem with very specific variables that need to be chosen with a particular goal in mind. You can focus on getting the absolute best results possible at one particular distance, such as in a benchrest rifle that's always shot at 50 yards, or you can compromise on some medium distance that will still give you good results at shorter and longer distances. But you still need to choose a region that you want to work in. No barrel shoots good at all distances. The physics of the problem make that an impossibility. The barrel vibrates a certain way in response to firing. And the behaviour of those vibrations in relation to muzzle exit timing dictates how it will shoot. In this second image the system is tuned to shoot best at 50 yards. But each bare barrel contour and length will have its own ideal distance to shoot at. The distance at which those two shots will meet each other changes based on that.

thanks for the tuner lesson, I had it all wrong. if I understand this correctly one could accomplish the same thing as a tuner by cutting the barrel at a precise point where the barrel vibration is optimal for bullet trajectory given the difference in velocity with a particular lot of ammo at a certain distance.

yes, but a tuner is slightly more user friendly, adjustable variability for conditions and ammo de jourif I understand this correctly one could accomplish the same thing as a tuner by cutting the barrel at a precise point where the barrel vibration is optimal

Yes, temperature affects how things vibrate. Get a couple tuning forks that sound the same when you strike them both when they’re at the same temperature and experiment with putting one in the freezer and heating one up under the hot water tap and then striking them both again. Being able to spin the tuner outer body can be quite helpful.

It's not a secret that antimony is used to harden .22LR bullets. Not much is required or used.ps: if rimfire bullets contain antimony and/or tin it is precious little

You are absolutely right that the best CF performance comes with hand loaded ammo. Reloading for .22LR is a different story.I'll make a statement that getting the greatest accuracy from a centerfire rifle one must handload and this is why I believe the same must be true for rimfire as well.

There is no good supply of pre-primed brass casings available (Cutting Edge supplied CCI-produced primed casings which are not comparable to the primed casings used by match ammo makers). This is not likely to change. The price of Cutting Edge monolithic bullets made the resulting ammo comparable in cost with top tier match ammo. Performance was never nearly as good. Reloading .22LR to make ammo at least as good as match ammo isn't realistic.

Still not true. There's a very good reason why no one reads about "50 yard barrels" or "100 yard barrels". It's because it's not a thing.all barrels shoot best at one distance