Buttstock Extension w/pics

Guntech and Sean, thank you for your input. In the interest of making this thread educational, I am posting some pics of what Guntech visualised and has probably dealt with before.

The pics show what appears to me, to be work done by several people. The original finish was so thick it had depth to it, almost as if it had been dipped. The checkering was filled in and Bubba over-sanded the points ahead of the checkering. That wood is gone, never to return. After half a day with a brass wire brush, and a whole can of Circa 1850, I was able get the "Mr. Mike's" (BC joke) table finish off. Fortunately the checkering is mostly there and I will be able to re-point it.

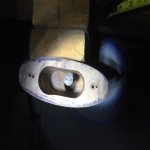

Now as for the attachment at the butt, you can see my possibilities. With two sets of previous attachment holes, carefully using the 5/16 Deck screws will give me plenty of holding power in new wood, under the flat heads. I also have the option of threading in the ready rod and attaching to it, along the lines of Sean's thinking. I need to keep a flat surface under the Morgan base, as the main adjusting bolt is trapped in a slot, and cannot be allowed to drop out.

So to further seek wise counsel, check out the picture against the light. This is a "knob" at the end of the strip down the comb. Bear in mind, I am retired and this is not a collector piece, but a shooter for trap doubles locally. After my half day with the Circa 1850, whatever this knob and strip are made of it is still there. When you tap on the comb top or knob, it sounds almost like glass. It is very hard and well attached. I am sure my belt sander will be able to cut it, as the comb is too high. Here is my question. What is this product that is impervious to Circa 1850 and lots of acetone? Maybe Ian Robertson is following along.