I have a Dillon 650 (had it for about 6 years now at a guess) and it has loaded a LOT of rounds.

Its needed a few tweaks and some TLC along the way (I did a decent sized overhaul earlier this year and replaced a bunch of worn looking parts / springs etc and polished a bunch of things which has gotten ragged through wear and tear).

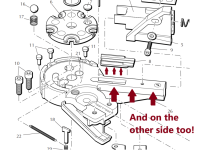

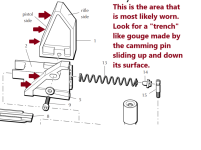

It runs 99% but one niggling issue which keeps happening is that the case (its setup for 9mm 90% of the time) drops, gets pushed into the station one location on the press (I can watch it slide right into the shellplate and seat correctly) but for some reason the case sometimes slides back out a little (its pretty sporadic - I cant see any underlying cause or pattern) which causes the edge of the case to hit the decapping / resizing die in station 1 and lock everything up.

Its an easy fix (simply reach around and push the case in a little to where it should be).

The station 1 locator (Dillon option 5) looks pretty worn and I wonder if it could be worn to the point that it is a little thinner than it should be and therefore not at the same level as the shellplate which means the case is tipped back a little and falls out of the shellplate cup.

Thoughts?

Its needed a few tweaks and some TLC along the way (I did a decent sized overhaul earlier this year and replaced a bunch of worn looking parts / springs etc and polished a bunch of things which has gotten ragged through wear and tear).

It runs 99% but one niggling issue which keeps happening is that the case (its setup for 9mm 90% of the time) drops, gets pushed into the station one location on the press (I can watch it slide right into the shellplate and seat correctly) but for some reason the case sometimes slides back out a little (its pretty sporadic - I cant see any underlying cause or pattern) which causes the edge of the case to hit the decapping / resizing die in station 1 and lock everything up.

Its an easy fix (simply reach around and push the case in a little to where it should be).

The station 1 locator (Dillon option 5) looks pretty worn and I wonder if it could be worn to the point that it is a little thinner than it should be and therefore not at the same level as the shellplate which means the case is tipped back a little and falls out of the shellplate cup.

Thoughts?