Brass IR emissivity sits in a wide range, shiny things are generally pretty hard to measure with IR, calibrating the measuring device could be tricky. Some IR guns come with K type thermocouple for setup and verification.Finally got the water pump this evening. I am also having some brainstorming now with the stupid water system.

The ZVS original copper tube OD is 5mm.... I don't want to solder another 1/4" tube over a 5mm to build up a wall thickness for a silicon tube because a stupid water radiator barb is 8mm. My plumbing soldering skills are pure basics only.

I will go tomorrow to a plumbing store or HD if I can find - a plastic - inline barb fitting, not really inclined to have another metal piece between wires.

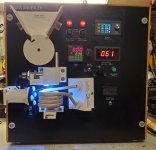

For now I will finish this my brass annealing ZVS project with a count down timer what I currently have, of course same all components mounted on a piece of plywood sheet.

When time comes to move all to a enclosure, I have in my plans to control the annealing not by timer but buy IR/laser Temp controller.

Set the Temp for let say 400 C or 450 C or 500 C where the controller will cut ... and that can give a best samples to compare the material.

Handheld IR guns also have height over bore aiming issues since the visible and IR light sources are not coaxial.

https://www.thermoworks.com/emissiv...18-ku1usXZtQFiIGxPI2Ppc2ISF2LtY-ZSHkoq4wiGSw-

https://blog.thermoworks.com/infrared-thermometry/