As a prelude, I've been shooting long range for about 5 years now ( been handloading and shooting/hunting for 35yrs +).

I can keep, under good conditions, 0.4 - 0.75 moa at 1048 yards for 5 shots and ~1 moa for 10 shots.

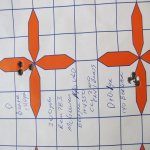

What is killing my groups is horizontal dispersion. To that end new bags and front rest were purchased, out this am with next to no wind at 200m, and that horizontal is still there (BTW the rifle and load has gone 5 1/16" at 1048 yds in practice). I realize that it will take some practice with the new bench set up.

Does anyone in the long range community have any 'tips' I can work on to reduce this problem?

https://lh3.googleusercontent.com/p...?key=NWJNcHZmdTNkYUp4RHVuaGluWV8ydFhQeDhORVJn

200m/219yards

I can keep, under good conditions, 0.4 - 0.75 moa at 1048 yards for 5 shots and ~1 moa for 10 shots.

What is killing my groups is horizontal dispersion. To that end new bags and front rest were purchased, out this am with next to no wind at 200m, and that horizontal is still there (BTW the rifle and load has gone 5 1/16" at 1048 yds in practice). I realize that it will take some practice with the new bench set up.

Does anyone in the long range community have any 'tips' I can work on to reduce this problem?

https://lh3.googleusercontent.com/p...?key=NWJNcHZmdTNkYUp4RHVuaGluWV8ydFhQeDhORVJn

200m/219yards