- Location

- Northeastern Ontario

Most shooters probably never measure their .22LR ammunition. Most shooters probably understand that the less expensive bulk ammo is not as consistent in terms of exact dimensions, weight, rim thickness -- and most obviously in the target results downrange. They instead rely on the knowledge that generally speaking match ammo is much more consistent in all the ways mentioned, and in target results. In fact shooters who use match ammo assume or expect that the more expensive it is the more consistent it will be in all ways.

There are several measurements, at least three potentially significant ones, that can be made with regard to .22LR ammo. What follows here is not to argue which is most important to what ultimately counts in .22LR ammo -- consistent accuracy. It is instead a foray into what may make a difference in accuracy and what some shooters measure in their pursuit of it. I may have things wrong at times and of course welcome corrections and comments.

First is measuring and sorting .22LR ammo by rim thickness variation, which has been discussed in this forum in recent threads. The fact is that rim thickness can vary a great deal, especially in bulk ammo. Mid-grade ammo has rim thickness variation up to 0.006". High end ammo, such as Eley Tenex or Lapua Midas, generally has much tighter tolerances. Shooters who measure rim thickness usually sort the ammo by different ranges of thickness into which the ammo falls. There are various methods that are used to make rim measurements, from commercially available products to innovative do-it-yourself alternatives.

I won't make any comments here about how important or useful measuring rim thickness may be, except to note that serious shooters who use high end ammo may have done it in the past, when this idea was first popularized several decades ago, but generally do not do it now.

A second measurement some shooters make, and which has also been discussed a little in this forum, is measuring base-to-ogive. This measurement shows that there is variation in .22LR ammo from the base of the rim to the ogive of the bullet, a measurement that is probably more familiar to centerfire hand loaders. In .22LR ammo variances in rim base-to-ogive lengths of .025". Top tier ammo is much more consistent, with 80% falling within .008" rim base-to-ogive length spread, according to a 2013 report in AccurateShooter dot com.

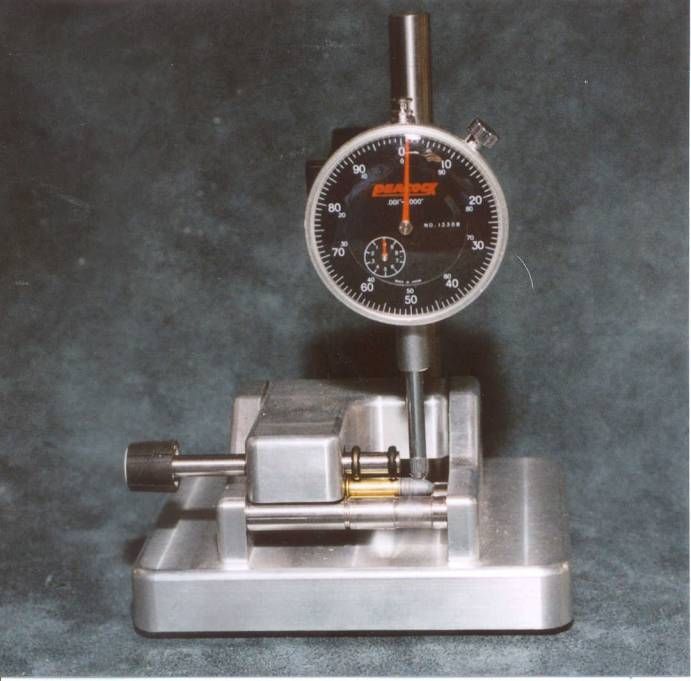

There are various methods to measure base-to-ogive length, including commercially available gauges and homemade ones. Below is one made specifically for measuring base to ogive.

How effective is measuring base-to-ogive length? I don't know. But here's some information showing results from one shooter using one rifle and sorted ammo. You can draw your own conclusions, if any.

This information is taken from h t t p://bulletin.accurateshooter.com/2013/02/g3-rimfire-rim-thickness-tool-and-base-to-ogive-length-gauge/

A third measurement concerns case-to-bullet concentricity. It may be familiar to centerfire reloaders and perhaps to .17HMR shooters, but it is not often discussed with regard to .22LR ammunition. I'll give some information about that in another post.

There are several measurements, at least three potentially significant ones, that can be made with regard to .22LR ammo. What follows here is not to argue which is most important to what ultimately counts in .22LR ammo -- consistent accuracy. It is instead a foray into what may make a difference in accuracy and what some shooters measure in their pursuit of it. I may have things wrong at times and of course welcome corrections and comments.

First is measuring and sorting .22LR ammo by rim thickness variation, which has been discussed in this forum in recent threads. The fact is that rim thickness can vary a great deal, especially in bulk ammo. Mid-grade ammo has rim thickness variation up to 0.006". High end ammo, such as Eley Tenex or Lapua Midas, generally has much tighter tolerances. Shooters who measure rim thickness usually sort the ammo by different ranges of thickness into which the ammo falls. There are various methods that are used to make rim measurements, from commercially available products to innovative do-it-yourself alternatives.

I won't make any comments here about how important or useful measuring rim thickness may be, except to note that serious shooters who use high end ammo may have done it in the past, when this idea was first popularized several decades ago, but generally do not do it now.

A second measurement some shooters make, and which has also been discussed a little in this forum, is measuring base-to-ogive. This measurement shows that there is variation in .22LR ammo from the base of the rim to the ogive of the bullet, a measurement that is probably more familiar to centerfire hand loaders. In .22LR ammo variances in rim base-to-ogive lengths of .025". Top tier ammo is much more consistent, with 80% falling within .008" rim base-to-ogive length spread, according to a 2013 report in AccurateShooter dot com.

There are various methods to measure base-to-ogive length, including commercially available gauges and homemade ones. Below is one made specifically for measuring base to ogive.

How effective is measuring base-to-ogive length? I don't know. But here's some information showing results from one shooter using one rifle and sorted ammo. You can draw your own conclusions, if any.

This information is taken from h t t p://bulletin.accurateshooter.com/2013/02/g3-rimfire-rim-thickness-tool-and-base-to-ogive-length-gauge/

A third measurement concerns case-to-bullet concentricity. It may be familiar to centerfire reloaders and perhaps to .17HMR shooters, but it is not often discussed with regard to .22LR ammunition. I'll give some information about that in another post.