OK, here's the story. I'm in the process of reassembly of an antique Smith & Wesson. It looked pretty sad when I got it and I did a lot of work to prep it for a bluing job (big thanks to Jason at Gunco) and it was coming together nicely. One moment of frustration and just a touch too much force on a 100 yr. old plus part and "SNAP"!! I broke a little leaf spring right at the joint. As parts for these old pistols are on the "unobtainium" list, I either have to find a modern spring that I can alter to suit or see if someone can microweld the sucker for me. Any input would be most appreciated. I don't mind mailing it out if there's no one in the GTA. You can see why I wanted it restored.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Micro welding?

- Thread starter LawrenceN

- Start date

- Location

- Western Manitoba

I am not a welder or blacksmith - perhaps you have your reasons for wanting to use that part? When I was apprentice, one of the Journeymen from Austria would make stuff like that - he said to work steel, was a common "every tradesman knew how to do that" in his day. I never learned how, but I think to make a flat spring is a pretty basic gunsmith / blacksmith type of task - might be an option for you, versus trying to get that piece welded??

Welding doesn't work well on springs. You'd be better off making a new one from flat steel of the correct dimensions. - dan

THIS. As soon as you apply enough heat to weld metal together, it will destroy the springiness..Welding doesn't work well on springs. You'd be better off making a new one from flat steel of the correct dimensions. - dan

No promises by any means...but I have tons of old gun parts like that.OK, here's the story. I'm in the process of reassembly of an antique Smith & Wesson. It looked pretty sad when I got it and I did a lot of work to prep it for a bluing job (big thanks to Jason at Gunco) and it was coming together nicely. One moment of frustration and just a touch too much force on a 100 yr. old plus part and "SNAP"!! I broke a little leaf spring right at the joint. As parts for these old pistols are on the "unobtainium" list, I either have to find a modern spring that I can alter to suit or see if someone can microweld the sucker for me. Any input would be most appreciated. I don't mind mailing it out if there's no one in the GTA. You can see why I wanted it restored.

Perhaps laying alongside a ruler or a couple snaps of it held in calipers?

It's my hope that the temper would only be drawn at the knuckle and the wings would retain their spring. To tokguy, I'll take pics with a ruler or caliper for dimension. Thank you.,THIS. As soon as you apply enough heat to weld metal together, it will destroy the springiness..

Licensed to kill

CGN Regular

- Location

- Peace Country Alberta

I suppose you could TIG weld it with a rod of spring steel. However, you can make one of those way easier and faster than welding IMO.

You can weld it but it'll break. A welding rod or wire will not be the same composition so you'd have different metals that won't work together and it will simply break. I know this. Making springs is actually easy. If you look on the youtube Larry Potterfield may be able to help you out.

chaos junkie

Member

- Location

- Quesnel BC

here is a video of a gunsmith making a spring

Lawrence, whats your gun show schedule the rest of the month. I have tons of spring steel blanks, I can give you some lengths if you have a torch and some files and feel like spending a day in the shop, or I can take a stab at making one for you. Which spring in the gun is it?

You can weld it but it'll break. A welding rod or wire will not be the same composition so you'd have different metals that won't work together and it will simply break. I know this. Making springs is actually easy. If you look on the youtube Larry Potterfield may be able to help you out.

This is the case - without knowing the exact composition of the original spring, you will never get a match.

Also - WAY too much work - that is an incredibly simple spring.

Jonnyofalltrades

Regular

- Location

- North-central Saskatchewan

That is one of the simplest shaped flat springs I've ever seen. Usually they have complicated features of some sort that makes reproducing them interesting.

Just make it. Spring stock, hacksaw, files, sandpaper, propane torch. Literally all you need.

Welding would hold until you tried to install it in the gun. Then it would break.

Guaranteed.

Just make it. Spring stock, hacksaw, files, sandpaper, propane torch. Literally all you need.

Welding would hold until you tried to install it in the gun. Then it would break.

Guaranteed.

you can rough the shape with a grinder but you must file it very smooth before you heat and shape it. When you heat it you go until its non magnetic and quench it in oil. After it has cooled in the oil heat it with your torch only hot enough to smoke the oil off of it. If you leave a scratch from the grinder the spring will most likely break there.

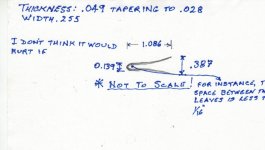

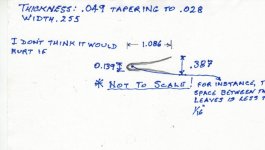

To all of you, thank you for your input. I'm pretty handy but I'm a woodworker (or was) and living in an apartment and not having a shop, making a spring would be easy for some but out of my wheelhouse. I'm attaching a scan of the spring NOT TO SCALE, but the dimensions are accurate. If some kind soul had something, or could fabricate something suitable, I would pay them for their time and material. Thank you all again.

Good day! Off to Milton this Sunday (22nd.) and Orangeville (29th.)Lawrence, whats your gun show schedule the rest of the month. I have tons of spring steel blanks, I can give you some lengths if you have a torch and some files and feel like spending a day in the shop, or I can take a stab at making one for you. Which spring in the gun is it?

Attachments

No promises by any means...but I have tons of old gun parts like that.

Perhaps laying alongside a ruler or a couple snaps of it held in calipers?I I took some pics and attached a drawing with dimensions. Look it over and let me know if you have anything in your inventory that you think would either work or could be altered/adapted to work.