- Location

- Beaverlodge, Alberta

Hey guys I'm going to try rust bluing on a couple of old sporters of mine. I'm doing a Ross MkIII bubba first as it was bought a wreck and I've been improving it ever since.

I want to do a nice rust blue on all the parts. Wondering what ppl have used to prep the small parts like the rear site components etc. What do you use to prep all of the metal?

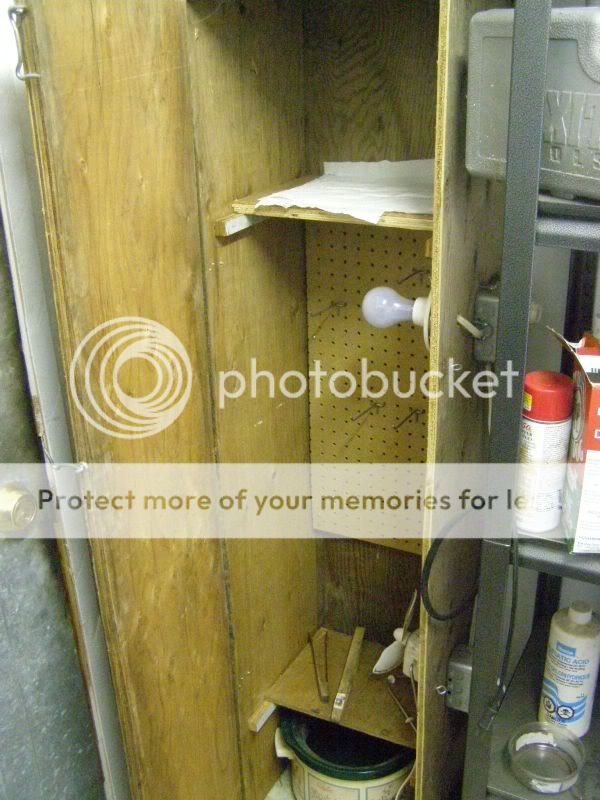

I am building a boiling tank and have a good idea of what I will use for a rust cabinet and to card the steel. I would't mind being able to get onto prepping it while I wait for my solution to get here.

Thanks in advance

I want to do a nice rust blue on all the parts. Wondering what ppl have used to prep the small parts like the rear site components etc. What do you use to prep all of the metal?

I am building a boiling tank and have a good idea of what I will use for a rust cabinet and to card the steel. I would't mind being able to get onto prepping it while I wait for my solution to get here.

Thanks in advance