Was out shooting with a couple of friends on the weekend and one of them brought a Gen 3 Type 97. We noticed that when the barrel heated up the POI walked up the paper almost a foot (at 100 yards) after 25 rounds. Here's what was happening:

(Arrows indicate POA for each group, numbering corrected - we mis-labeled them at the time)

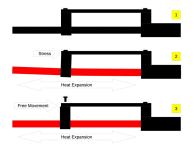

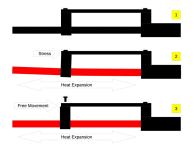

We checked to make sure everything was tight, nothing loose, nothing shifted. After letting the barrel cool the POI returned to the POA (as in group 1 above). We took off the handguard and rail to look things over, and noticed that when the rail was screwed down it effectively made a rigid bridge between the receiver and the gas block (Figure 1). We figured that as the barrel heated up it would try to expand lengthwise and the rigid rail would cause it to flex upward as it tried to stretch (Figure 2). So we removed the front rail screw to break the rigid connection and allow the barrel to expand lengthwise freely as the Gen 1 would do (Figure 3) to test the theory.

We stretched some bike inner tube around the front of the rail and the handguard to try to keep the rifle returning properly to zero(-ish) after each shot, and put 40 rounds through an initially-cold barrel as quickly as we could aim and fire. Here's the result (POA was the 2" sticker cluster in the centre):

POI changed a couple of inches with the removal of the forward screw from the rail but, most critically, it didn't shift as the barrel heated. Caveat: This was one rifle, hardly a statistically-significant sample.

So I offer these results to the collected wisdom of CGN. Has anyone with a Gen 2 or Gen 3 T97 noticed similar behaviour as their barrel heated? Has anyone tried removing the front rail screw to see if that fixed it? Does anyone want to try it themselves and add to the statistical sample size?

Also, since a ranger band holding the front of the rail in place seems little less than ideal (though it worked better than I expected), does anyone have any ideas for how to secure the rail to the gas block properly without introducing torque as the barrel heats and expands?

[Notes on shooting conditions: Warm dry day, light breeze, red & black stickers are 1" square, black stickers are 0.87" square, centre of second target is 4 squares. Same shooter took all shots, same ammo was used for all shots (UMC .223 55gr FMJ), optic was a Vortex Spitfire 3x, all shots taken at 100 yards off a bag. Targets shown had no other shots taken on them except the tests from the T97 in question. The first target was 5 carefully-aimed groups of 5 shots, the second target was 40 rapid-fire shots taken as quickly as he could change mags.]

(Arrows indicate POA for each group, numbering corrected - we mis-labeled them at the time)

We checked to make sure everything was tight, nothing loose, nothing shifted. After letting the barrel cool the POI returned to the POA (as in group 1 above). We took off the handguard and rail to look things over, and noticed that when the rail was screwed down it effectively made a rigid bridge between the receiver and the gas block (Figure 1). We figured that as the barrel heated up it would try to expand lengthwise and the rigid rail would cause it to flex upward as it tried to stretch (Figure 2). So we removed the front rail screw to break the rigid connection and allow the barrel to expand lengthwise freely as the Gen 1 would do (Figure 3) to test the theory.

We stretched some bike inner tube around the front of the rail and the handguard to try to keep the rifle returning properly to zero(-ish) after each shot, and put 40 rounds through an initially-cold barrel as quickly as we could aim and fire. Here's the result (POA was the 2" sticker cluster in the centre):

POI changed a couple of inches with the removal of the forward screw from the rail but, most critically, it didn't shift as the barrel heated. Caveat: This was one rifle, hardly a statistically-significant sample.

So I offer these results to the collected wisdom of CGN. Has anyone with a Gen 2 or Gen 3 T97 noticed similar behaviour as their barrel heated? Has anyone tried removing the front rail screw to see if that fixed it? Does anyone want to try it themselves and add to the statistical sample size?

Also, since a ranger band holding the front of the rail in place seems little less than ideal (though it worked better than I expected), does anyone have any ideas for how to secure the rail to the gas block properly without introducing torque as the barrel heats and expands?

[Notes on shooting conditions: Warm dry day, light breeze, red & black stickers are 1" square, black stickers are 0.87" square, centre of second target is 4 squares. Same shooter took all shots, same ammo was used for all shots (UMC .223 55gr FMJ), optic was a Vortex Spitfire 3x, all shots taken at 100 yards off a bag. Targets shown had no other shots taken on them except the tests from the T97 in question. The first target was 5 carefully-aimed groups of 5 shots, the second target was 40 rapid-fire shots taken as quickly as he could change mags.]