Slugs are fun to shoot, but too expensive at $1.00 a pop.

I have been making my own. One way is to cast a lead slug (or ball) and stuff it in a target round (after dumping out the shot).

The other way is to make wax slugs.

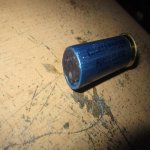

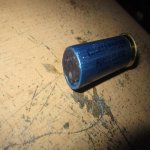

With either method, the cheap and easy way to proceed is to cut the crimp out of a target load. I like the 2 3/4 dram mild target loads. Buy cutting out the crimp, leaving the folded over section to hold the wad in place, the result is a ridge to hold the lead slug in place or to hold the wax slug in place, so it does not pop out under recoil.

My 11 year old grandson enjoys blowing up jugs of water with wax slugs. The recoil of the mild target loads in not too much for him

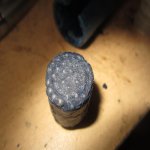

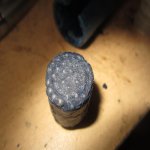

The concept of the wax slug is that the round has a full charge of lead shot plus hot wax to hold the shot as a solid cylinder. The wax and shot is heated up on the stove and then poured into the shell. It hits hard, just like a real slug, except it is cheap and has no ricochet risk.

I shot a short video of how I make wax slugs. The key trick is an easy way to get the crimp off. I use a 16mm ceramic drill bit in my electric drill. This cuts out the crimp easily.

I have been making my own. One way is to cast a lead slug (or ball) and stuff it in a target round (after dumping out the shot).

The other way is to make wax slugs.

With either method, the cheap and easy way to proceed is to cut the crimp out of a target load. I like the 2 3/4 dram mild target loads. Buy cutting out the crimp, leaving the folded over section to hold the wad in place, the result is a ridge to hold the lead slug in place or to hold the wax slug in place, so it does not pop out under recoil.

My 11 year old grandson enjoys blowing up jugs of water with wax slugs. The recoil of the mild target loads in not too much for him

The concept of the wax slug is that the round has a full charge of lead shot plus hot wax to hold the shot as a solid cylinder. The wax and shot is heated up on the stove and then poured into the shell. It hits hard, just like a real slug, except it is cheap and has no ricochet risk.

I shot a short video of how I make wax slugs. The key trick is an easy way to get the crimp off. I use a 16mm ceramic drill bit in my electric drill. This cuts out the crimp easily.