notsorichguy

CGN Ultra frequent flyer

- Location

- The city that rhymes with fun

So back in February I picked up a Springfield Armouries M1A from Prophet River. I decided to splurge before the dollar really sh*t the bed! Turns out it was a pretty good idea, because the same rifle is now priced $3-400 higher!

The problem was (not really a problem) the rifle shot only “passably” well. I have a tuned Nork that I have $1000 into that shot half the size groups with cheap Nork ammo! At the m-14 boot strap clinic in May it really brought the point home.

http://www.canadiangunnutz.com/forum/showthread.php/1142830-2015-Saskatoon-amp-Area-M14-Bootstrap-Clinic-May-23rd-amp-24th

For quite a while I was bouncing back and forth about what to do..... Spend a few bucks and do some upgrades (probably in the neibourhood of $500). Finally I decided to just see what was up with the rifle.

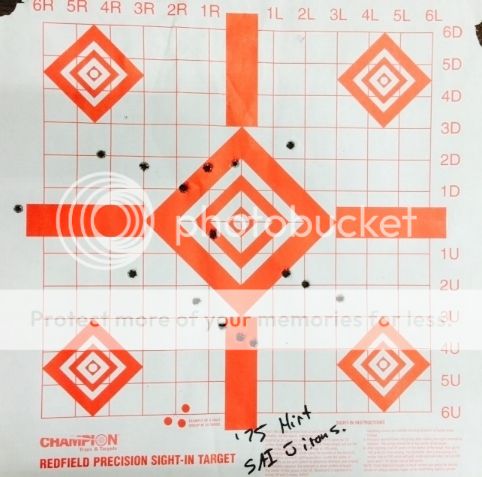

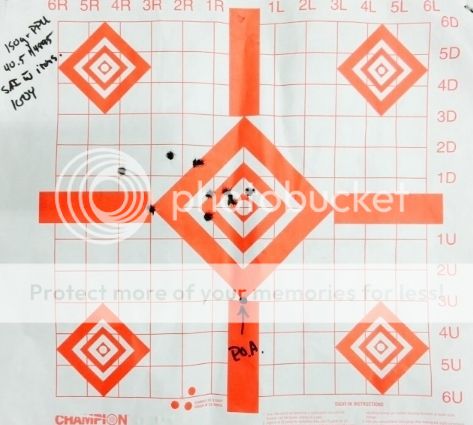

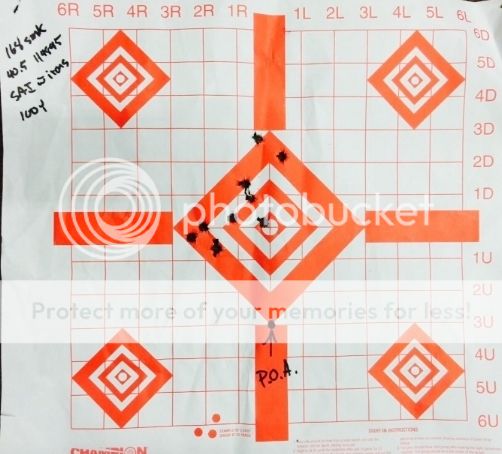

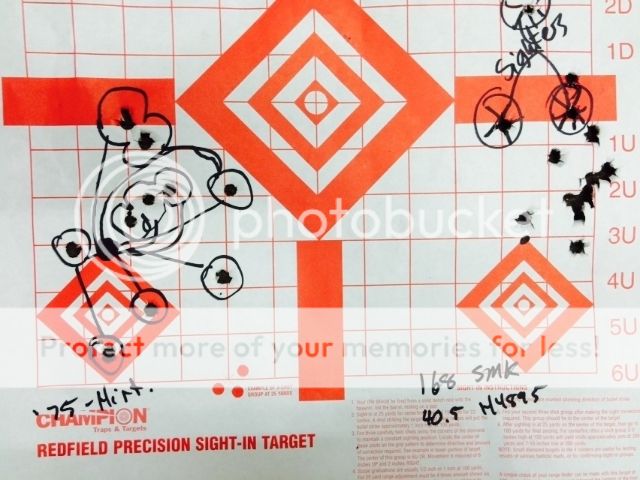

Shooting with the irons was a depressing affair on paper. I know I can shoot irons as I have a NM sight set on a tuned Nork and I can reliably hit coke cans and soup cans at 100 & 50% hits at 200y. Here are a few examples of how the M1A does with irons;

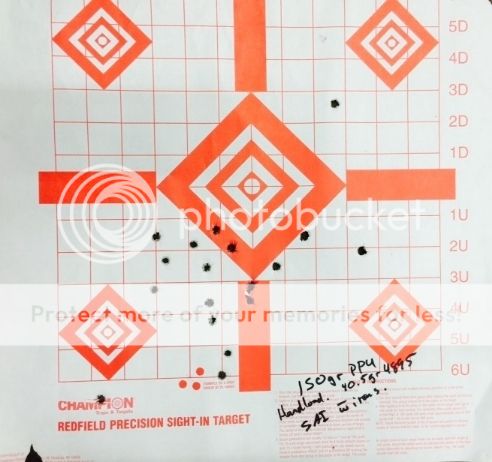

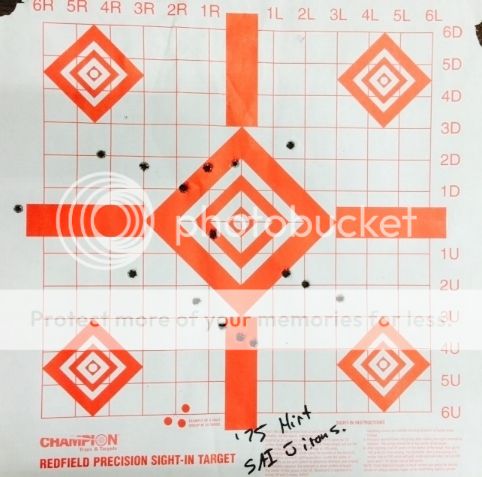

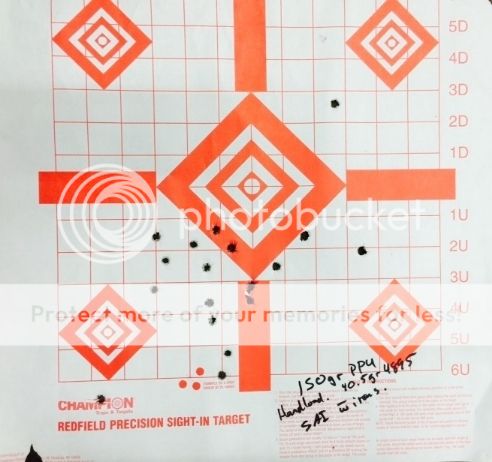

So then I decided to scope it and see what it can do. I slapped (I didn't really just "slap" it on.... I was at the bench for about 2-3 hrs getting it set "just right") on a scope (Redfield Revolution 4-12x40) and went to the range!

Honestly I was both surprised and disappointed.... I was surprised that it confirmed what I already thought.... 1) The irons were NFG (The front sight was marked NM 062 so it was probably OK). 2) The Hirtenburger ammo is OK, but my Handloads are better! 3) The rifle actually had some promise to be a shooter with some tweaking.... (I really honestly believe that something can be done about the vertical stringing)..... I guess I was disappointed that the rifle needed tweaking, for $2300 after taxes and shipping I was really expecting something better... At the same time I find my “Zen” at the bench futzing with these things!

So bag it, I’m doing it!

Now this is where it gets very very interesting...... I have in the past done the “local welding shop Timmy’s XL-DD tig welding”..... NEVER AGIAN!!!!! Here’s why....

I printed out a step by step guide (from a post by 45acpking) and gave it to the welder; I don’t think he read it.... I had a jig made up by a high school shop teacher I know, it wasn’t perfect, but it did the trick! it kept the gas system from twisting like a pretzel from over penetration and too much heat..... The gas system above is useable, just ugly....

So I am going to send off the gas system to somebody.... Casey at Tac-ord gets the nod from 45ACP King and Tactical teacher, so plan on sending it to him.

Now I’m thinking bedding.... I have done many many bolt guns. Never done an M-14.... Then TonyBen releases his videos on bedding.....

http://www.canadiangunnutz.com/forum/showthread.php/1259573-M14-M1A-M305-Glass-bedding-video-series-**All-parts-done!!**

Well f-this! That’s too much work and way too much time and effort..... But nobody this side of the border I talked to or emailed would do it...... Not even Casey at Tac-ord.

I almost scrapped the whole idea and sold the rifle! lol

Then I watched Tony’s videos again..... And then a 3rd time. And then I subscribed to his YouTube channel and watched every single video he has made, some of them 2 or 3 times! I then re-discovered all the stickies in the MBR forum.....

Long story longer..... I decided that if it was going to get done, I had to do it myself!

This is when the $$$ starts to flow.....

I packed up the gas cylinder and shipped it off to Tac-ord ($12.50 postage) ($91 for the work and return postage... Worth Every Penny!)

Ordered up a NM Flash hider and a NM rear sight from SPCamno (CGN member) $80 & $150 and shipping

Gas shims from Tactical teacher ($1 ea, so I ordered up a bunch)

NM Spring op-rod guide and 1million round spring from the parts bin ($39 iirc) from S&J hardware iirc....

Then since I’m ordering a bunch of parts and tools from Brownelles (different thread/story), I order up a Springfield NM hooded aperture..... $45.99 USD... (Oh, and something I didn’t know.... It needs to be fitted! It will not just drop in) and a set of sight protectors ($12 USD front and $12 USD Rear) so all in about $100 CDN.

So at this point I’m at $490...... I already have the devcon and plastercine as well as the tungoil etc. (I’ll get there)....

First off, let’s blow this pig apart and see what is actually wrong.....

The op-rod guide is a bit loose, so it will need to be knurled (peened actually cuz I’m too cheap to pay for a knurler)

The gas system key-ways will have to be peened so that there is no side to side play

The bolt roller impacts the receiver

The FH has some rotational movement so that will have to be peened as well

And what’s this, the barrel is slightly under indexed! (By like 3 degrees, easy fix with the barrel and action blocks.... But really SAI, Really...) 3 degrees is actually in spec, before I got my Starret angle finding gauges my level would have been saying “it’s good”!

The stock front ferule impacts hard onto the front band

The op-rod guide touches the stock

The hand guard is cheap flimsy plastic and touches everything! The stock, the receiver, the oprod..... (Add up another $20 for a USGI fibreglass hand guard from the parts bin)

The guide rod retaining pin will have to be shortened (for the bedding)

*** At this point, the savy will notice that these are all things us Chinese/Nork/Poly rifle "tweakers" have been doing for years!***

So I start to work.... But the gas system is in the mail to ON for welding... I’ll do what I can...

First off let’s relieve that front stock ferule. It does just pop right off! (Very little effort) I very carefully scribe the stock where the shoulder will have to get re-located to and use my calibrated mark 1 eyeball use my thumb as a guide and a hack saw to carefully cut the stock along the scribed line about 1/8” deep. And another 1/8th, and another 1/8th.... then I use the same saw to cut in using the old ferule “nub” as a guide and nibble off pieces of walnut to form a new shoulder in the stock. Once the rough shape is formed I very carefully use a rough file and sandpaper to get the final shape. I then cut the “nub” so that will be covered by the metal ferule. I rough up both surfaces and mix up some devcon and glue the 2 together!

Once that dries/cures I set the action back into the stock and mark where material needs to be taken out to clear the op-rod guide. Spin up the Dremel and have at ‘er!

Next up, clearance the front ferule for gas system clearance. (Same Dremel and sanding drum)

At this point I’m looking at my stock liner and thinking “uff-da”... Stock liner screwdrivers I have, the right size for this... I ain’t got..... I wind up taking an old flat head screwdriver thats been retired from my day job.... 30 min later (with a file no less) I have a perfectly fitted stock line screw driver!

I follow the instructions to the letter in Tony’s video, the stock liner get a good trimming.... I remove the finish where needed on the interior of the stock where the liner is going to go and hogg out the area the bedding compound is needed for the receiver legs. Then I bed in the stock liner using Devcon.

Disclaimer****

I was taking pictures through all of this but somehow my phone “lost” a bunch of pictures.... Some of the pictures that got “lost” were work related and really buggered me up at work, but that’s a different story altogether! But sorry, I haven’t any pics of this whole process!

****

At this point I’m at a standstill..... To continue I need a welded gas system.... But, then I remember that “chewed up” Nork system.... Why the heck not!

So I decided to bed the rifle using the “extra” gas system, I’m taking a gamble that the one I will be using will hook-up correctly, (as it turns out it works out perfectly)

I removed absolutely every single part from the barrelled action. ABSOLUTLY every single part, even the Bolt stop!

To make a fulcrum I take a bastardized version of Tonyben's idea (the coat hanger method is a no go for me I don’t want damage that pretty walnut). I took a piece of spruce 2x4, whittled away at it with a knife and a belt sander. Shaped it just right, wrapped it in electrical tape and used plastercine to “hold” it just right in the forend.

I used minwax wax for a release agent, which works very well, but doesn’t work as well as Tonyben’s recommended aerosol release agent (it can leave dimples or voids in the bedding).

I didn’t tape off the stock as I was planning on re-finishing it anyway (that may or may-not have been a mistake, but it worked fairly well in the end)

I used a Dremel, a file and a ¼” chisel to relieve the stock where bedding was to go.

Installed the fulcrum

Re-applied release agent (to make sure I got everything coated 2 or 3x)

Mixed up a goodly amount of Devcon

Took a deep breath and set to work!

The first result was “ok” but not too terribly good, lots of voids and pockets.

The second time I did a skim coat..... Still not good enough...

The 3rd time..... Good enough! (or at least good enough I could live with it!)

Over the next couple of days, as the bedding is curing, I re-jigger the Op-rod guide pin and put all the bits and pieces back onto the receiver.

And wait, "oh I'll paint in the markings etc." and wait, "hmm I'm going to white fill the sight marks etc." and wait.... the gas system isn’t back from Tac-ord yet, the NM hooded aperture isn’t here yet, and the stock hasn’t “dried” yet.....

Oh yeah... The stock.... Originally the ejector was dinging up the stock pretty bad and I though the oil finish could have been done better (fussy I know) so after bedding the stock and letting it cure for 3 days I sanded down the stock with 120 then 200 grit sand paper. Then I re-finished the stock using “Watco Danish Oil”. The way I was taught to use this stuff works really well. The first rifle stock I ever did was 20yrs ago, and this type of finish is still holding up after 20+ hunting seasons! First coat of oil was applied with a cotton rag, let stand (hang actually) in the warm +30c garage (its summer in SK) for about an hour, then re-apply another coat. But the second coat is “sanded in” using 400 grit wet-dry automotive paper. I do that twice a day (in the morning before work and in the evening after supper) for 2 days (4 applications). Then I switch to 600grit automotive wet-dry paper for 3 days (6 applications). Then a final heavy coat of oil finish is applied let stand for 2-3 days. Wipe off excess with a clean dry cotton rag/cloth (I have a gross of old, used “laundered” baby diapers). Let dry for a week. It should be dry to the touch and satin smooth! (there is a lot of waiting in between coats etc.)

Well just yesterday the Gas system came back from Tac-Ord! An absolutely beautiful job! I am very impressed! I finally got the rifle re-assembled last night. (The parts from Brownelles came in last week). I took some of pics as the assembly went along.

Well folks, if you’re still here, this is the pay off!

Unfortunately there are not any “after” groups just yet..... It's pissing rain, I don't feel like getting wet today! Hopefully Monday.... My schedule between Family and Hunting season is pretty full up.... I’m hoping I can get an afternoon off to go shoot some groups before Halloween! Ugh.... I'll probably have to mount up the Hi-Lux scope mount again... I really wish Basset would ship to Canada!

****Update****

Sept 6th 2015-09-06

I managed to sneak outta the house this morning....

I woke up at 6, not a creature was stirring!

The range has a "no noise" bylaw, so no shooting till 8am. I was at the bench at 8:01!

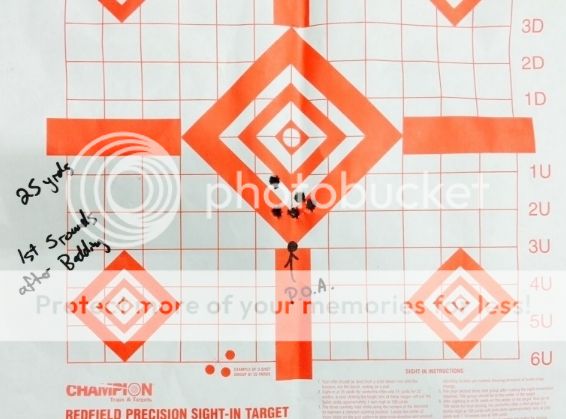

I managed OK groups, but it's hard to really shoot well when the air temp is cool (+6 to +9c) and the wind is gusting to 35-48 kph! (And of course I forgot my jacket) I was only able to spend 90min at the range, so just the irons today. At least it didn’t take long for the barrel to cool between groups!

The plan is to mount up a scope and try this again on a different day..... Hopefully before I head to Elk Camp on Friday after work....

I believe the pics will speak for themselves!

Final update Post # 13. Dec 4th 2015

The problem was (not really a problem) the rifle shot only “passably” well. I have a tuned Nork that I have $1000 into that shot half the size groups with cheap Nork ammo! At the m-14 boot strap clinic in May it really brought the point home.

http://www.canadiangunnutz.com/forum/showthread.php/1142830-2015-Saskatoon-amp-Area-M14-Bootstrap-Clinic-May-23rd-amp-24th

For quite a while I was bouncing back and forth about what to do..... Spend a few bucks and do some upgrades (probably in the neibourhood of $500). Finally I decided to just see what was up with the rifle.

Shooting with the irons was a depressing affair on paper. I know I can shoot irons as I have a NM sight set on a tuned Nork and I can reliably hit coke cans and soup cans at 100 & 50% hits at 200y. Here are a few examples of how the M1A does with irons;

So then I decided to scope it and see what it can do. I slapped (I didn't really just "slap" it on.... I was at the bench for about 2-3 hrs getting it set "just right") on a scope (Redfield Revolution 4-12x40) and went to the range!

Honestly I was both surprised and disappointed.... I was surprised that it confirmed what I already thought.... 1) The irons were NFG (The front sight was marked NM 062 so it was probably OK). 2) The Hirtenburger ammo is OK, but my Handloads are better! 3) The rifle actually had some promise to be a shooter with some tweaking.... (I really honestly believe that something can be done about the vertical stringing)..... I guess I was disappointed that the rifle needed tweaking, for $2300 after taxes and shipping I was really expecting something better... At the same time I find my “Zen” at the bench futzing with these things!

So bag it, I’m doing it!

Now this is where it gets very very interesting...... I have in the past done the “local welding shop Timmy’s XL-DD tig welding”..... NEVER AGIAN!!!!! Here’s why....

I printed out a step by step guide (from a post by 45acpking) and gave it to the welder; I don’t think he read it.... I had a jig made up by a high school shop teacher I know, it wasn’t perfect, but it did the trick! it kept the gas system from twisting like a pretzel from over penetration and too much heat..... The gas system above is useable, just ugly....

So I am going to send off the gas system to somebody.... Casey at Tac-ord gets the nod from 45ACP King and Tactical teacher, so plan on sending it to him.

Now I’m thinking bedding.... I have done many many bolt guns. Never done an M-14.... Then TonyBen releases his videos on bedding.....

http://www.canadiangunnutz.com/forum/showthread.php/1259573-M14-M1A-M305-Glass-bedding-video-series-**All-parts-done!!**

Well f-this! That’s too much work and way too much time and effort..... But nobody this side of the border I talked to or emailed would do it...... Not even Casey at Tac-ord.

I almost scrapped the whole idea and sold the rifle! lol

Then I watched Tony’s videos again..... And then a 3rd time. And then I subscribed to his YouTube channel and watched every single video he has made, some of them 2 or 3 times! I then re-discovered all the stickies in the MBR forum.....

Long story longer..... I decided that if it was going to get done, I had to do it myself!

This is when the $$$ starts to flow.....

I packed up the gas cylinder and shipped it off to Tac-ord ($12.50 postage) ($91 for the work and return postage... Worth Every Penny!)

Ordered up a NM Flash hider and a NM rear sight from SPCamno (CGN member) $80 & $150 and shipping

Gas shims from Tactical teacher ($1 ea, so I ordered up a bunch)

NM Spring op-rod guide and 1million round spring from the parts bin ($39 iirc) from S&J hardware iirc....

Then since I’m ordering a bunch of parts and tools from Brownelles (different thread/story), I order up a Springfield NM hooded aperture..... $45.99 USD... (Oh, and something I didn’t know.... It needs to be fitted! It will not just drop in) and a set of sight protectors ($12 USD front and $12 USD Rear) so all in about $100 CDN.

So at this point I’m at $490...... I already have the devcon and plastercine as well as the tungoil etc. (I’ll get there)....

First off, let’s blow this pig apart and see what is actually wrong.....

The op-rod guide is a bit loose, so it will need to be knurled (peened actually cuz I’m too cheap to pay for a knurler)

The gas system key-ways will have to be peened so that there is no side to side play

The bolt roller impacts the receiver

The FH has some rotational movement so that will have to be peened as well

And what’s this, the barrel is slightly under indexed! (By like 3 degrees, easy fix with the barrel and action blocks.... But really SAI, Really...) 3 degrees is actually in spec, before I got my Starret angle finding gauges my level would have been saying “it’s good”!

The stock front ferule impacts hard onto the front band

The op-rod guide touches the stock

The hand guard is cheap flimsy plastic and touches everything! The stock, the receiver, the oprod..... (Add up another $20 for a USGI fibreglass hand guard from the parts bin)

The guide rod retaining pin will have to be shortened (for the bedding)

*** At this point, the savy will notice that these are all things us Chinese/Nork/Poly rifle "tweakers" have been doing for years!***

So I start to work.... But the gas system is in the mail to ON for welding... I’ll do what I can...

First off let’s relieve that front stock ferule. It does just pop right off! (Very little effort) I very carefully scribe the stock where the shoulder will have to get re-located to and use my calibrated mark 1 eyeball use my thumb as a guide and a hack saw to carefully cut the stock along the scribed line about 1/8” deep. And another 1/8th, and another 1/8th.... then I use the same saw to cut in using the old ferule “nub” as a guide and nibble off pieces of walnut to form a new shoulder in the stock. Once the rough shape is formed I very carefully use a rough file and sandpaper to get the final shape. I then cut the “nub” so that will be covered by the metal ferule. I rough up both surfaces and mix up some devcon and glue the 2 together!

Once that dries/cures I set the action back into the stock and mark where material needs to be taken out to clear the op-rod guide. Spin up the Dremel and have at ‘er!

Next up, clearance the front ferule for gas system clearance. (Same Dremel and sanding drum)

At this point I’m looking at my stock liner and thinking “uff-da”... Stock liner screwdrivers I have, the right size for this... I ain’t got..... I wind up taking an old flat head screwdriver thats been retired from my day job.... 30 min later (with a file no less) I have a perfectly fitted stock line screw driver!

I follow the instructions to the letter in Tony’s video, the stock liner get a good trimming.... I remove the finish where needed on the interior of the stock where the liner is going to go and hogg out the area the bedding compound is needed for the receiver legs. Then I bed in the stock liner using Devcon.

Disclaimer****

I was taking pictures through all of this but somehow my phone “lost” a bunch of pictures.... Some of the pictures that got “lost” were work related and really buggered me up at work, but that’s a different story altogether! But sorry, I haven’t any pics of this whole process!

****

At this point I’m at a standstill..... To continue I need a welded gas system.... But, then I remember that “chewed up” Nork system.... Why the heck not!

So I decided to bed the rifle using the “extra” gas system, I’m taking a gamble that the one I will be using will hook-up correctly, (as it turns out it works out perfectly)

I removed absolutely every single part from the barrelled action. ABSOLUTLY every single part, even the Bolt stop!

To make a fulcrum I take a bastardized version of Tonyben's idea (the coat hanger method is a no go for me I don’t want damage that pretty walnut). I took a piece of spruce 2x4, whittled away at it with a knife and a belt sander. Shaped it just right, wrapped it in electrical tape and used plastercine to “hold” it just right in the forend.

I used minwax wax for a release agent, which works very well, but doesn’t work as well as Tonyben’s recommended aerosol release agent (it can leave dimples or voids in the bedding).

I didn’t tape off the stock as I was planning on re-finishing it anyway (that may or may-not have been a mistake, but it worked fairly well in the end)

I used a Dremel, a file and a ¼” chisel to relieve the stock where bedding was to go.

Installed the fulcrum

Re-applied release agent (to make sure I got everything coated 2 or 3x)

Mixed up a goodly amount of Devcon

Took a deep breath and set to work!

The first result was “ok” but not too terribly good, lots of voids and pockets.

The second time I did a skim coat..... Still not good enough...

The 3rd time..... Good enough! (or at least good enough I could live with it!)

Over the next couple of days, as the bedding is curing, I re-jigger the Op-rod guide pin and put all the bits and pieces back onto the receiver.

And wait, "oh I'll paint in the markings etc." and wait, "hmm I'm going to white fill the sight marks etc." and wait.... the gas system isn’t back from Tac-ord yet, the NM hooded aperture isn’t here yet, and the stock hasn’t “dried” yet.....

Oh yeah... The stock.... Originally the ejector was dinging up the stock pretty bad and I though the oil finish could have been done better (fussy I know) so after bedding the stock and letting it cure for 3 days I sanded down the stock with 120 then 200 grit sand paper. Then I re-finished the stock using “Watco Danish Oil”. The way I was taught to use this stuff works really well. The first rifle stock I ever did was 20yrs ago, and this type of finish is still holding up after 20+ hunting seasons! First coat of oil was applied with a cotton rag, let stand (hang actually) in the warm +30c garage (its summer in SK) for about an hour, then re-apply another coat. But the second coat is “sanded in” using 400 grit wet-dry automotive paper. I do that twice a day (in the morning before work and in the evening after supper) for 2 days (4 applications). Then I switch to 600grit automotive wet-dry paper for 3 days (6 applications). Then a final heavy coat of oil finish is applied let stand for 2-3 days. Wipe off excess with a clean dry cotton rag/cloth (I have a gross of old, used “laundered” baby diapers). Let dry for a week. It should be dry to the touch and satin smooth! (there is a lot of waiting in between coats etc.)

Well just yesterday the Gas system came back from Tac-Ord! An absolutely beautiful job! I am very impressed! I finally got the rifle re-assembled last night. (The parts from Brownelles came in last week). I took some of pics as the assembly went along.

Well folks, if you’re still here, this is the pay off!

Unfortunately there are not any “after” groups just yet..... It's pissing rain, I don't feel like getting wet today! Hopefully Monday.... My schedule between Family and Hunting season is pretty full up.... I’m hoping I can get an afternoon off to go shoot some groups before Halloween! Ugh.... I'll probably have to mount up the Hi-Lux scope mount again... I really wish Basset would ship to Canada!

****Update****

Sept 6th 2015-09-06

I managed to sneak outta the house this morning....

I woke up at 6, not a creature was stirring!

The range has a "no noise" bylaw, so no shooting till 8am. I was at the bench at 8:01!

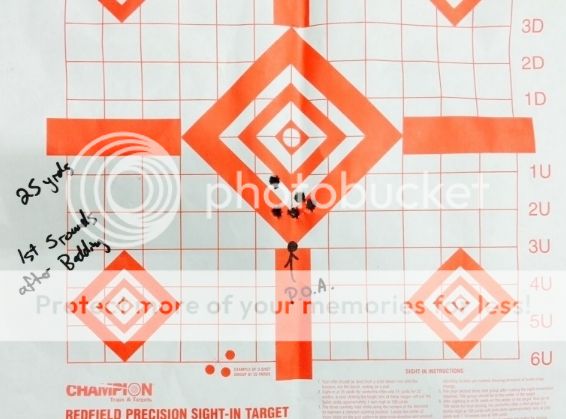

I managed OK groups, but it's hard to really shoot well when the air temp is cool (+6 to +9c) and the wind is gusting to 35-48 kph! (And of course I forgot my jacket) I was only able to spend 90min at the range, so just the irons today. At least it didn’t take long for the barrel to cool between groups!

The plan is to mount up a scope and try this again on a different day..... Hopefully before I head to Elk Camp on Friday after work....

I believe the pics will speak for themselves!

Final update Post # 13. Dec 4th 2015

Well....

To bring this post back from the edge of extinction! lol

It was a forecasted to be balmy +6 today (unheard of in South Sask)..... With winds gusting from the SE @ 35k (that's "normal").... I had the day off, so what the heck, let's go to the range!

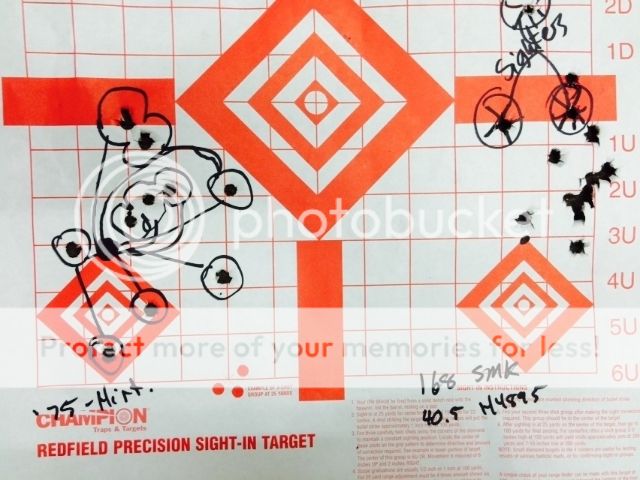

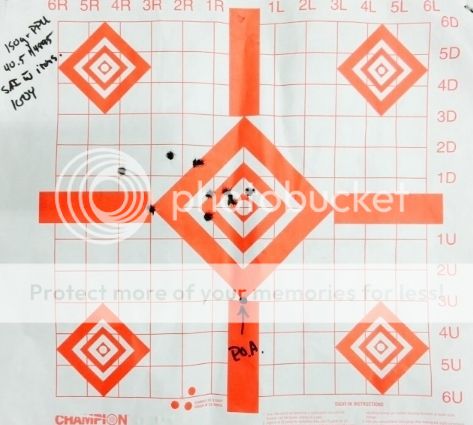

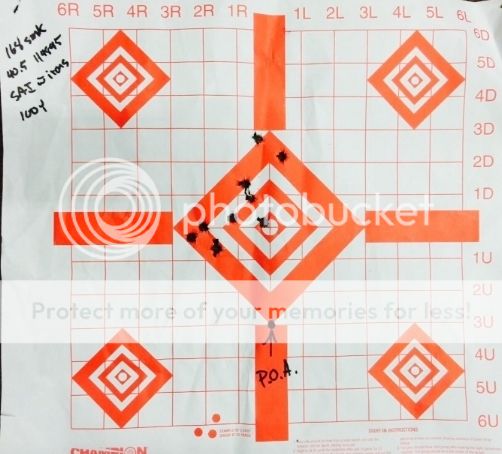

I've been playing with the '75 hirt that I got from Marstar (the berdan primed stuff). I figure if I can make up some "Mexican Match Ammo", it would be a "good" thing. I pulled 100 rnds and weighed the charges and weighed the projectiles and made up 4 10 round test groups that straddle the average charge weight. I also picked out 40 projectiles that were with-in 1% of the average projectile weight. There were only 65 projectiles (out of 100) that were with-in 3% of the mean projectile weight. I also took 10 pieces of primed brass and loaded up my "go-to" 168 SMK load.....

Here is the result!

Honestly I was hoping for better.

Next up I had loaded up 4 different types of brass with my "go-to" SMK load.... As you can see from the groups, I built the load with FC brass.... Big surprise the other types of brass didn't do as well....

Conclusion;

I have taken a M1A from a "solid" 8 inch gun, to a "solid" 5 inch gun (with any ammo you want) with a 2.5" (with my standard SMK load) honest to goodness "brag".....

$500 and a whole Schwack of time to cut the groups in half...... I'm pretty happy with that.....

I am going to continue down this particular rabbit hole, looking to hit 1.5"..... With-out swapping the barrel....

Next bit of "experimentation" will be with a Schuster adjustable gas plug..... We will see if that does anything! That will have to be a different thread....

Thanks for reading fellas!

Cheers!

Last edited: