Wallenstein

CGN Ultra frequent flyer

- Location

- Not the Fraser Valley

I have reloaded a set of once fired Federal cases, with CCI Large Rifle Primers and IMR 4895 powder (49 gr) and 147 gr FMJ Spire Point bullets.

I had checked case length before and after seating the bullets.

Following Lyman 50th Ed instructions.

The cartridges all loaded into my bolt action, but a couple of cases needed a bit of a push. They fired fine and ejected without any issue.

The results were about a 2 inch drop and an inch to the right of centre at 100 yds.

The right of centre could be just me though, I have noticed that I get that result with different rifles and may be down to me flinching or trigger control, especially once I have been through about 50 rds.

On cleaning the rifle I noticed some marks on the bolt face, round circular. The rifle has a couple of hundred rounds through it and this was the first re-loaded ammo I shot in it. Previously it had Barnaul and Federal through it. I can't be 100% sure the markings on the bolt face are new though.

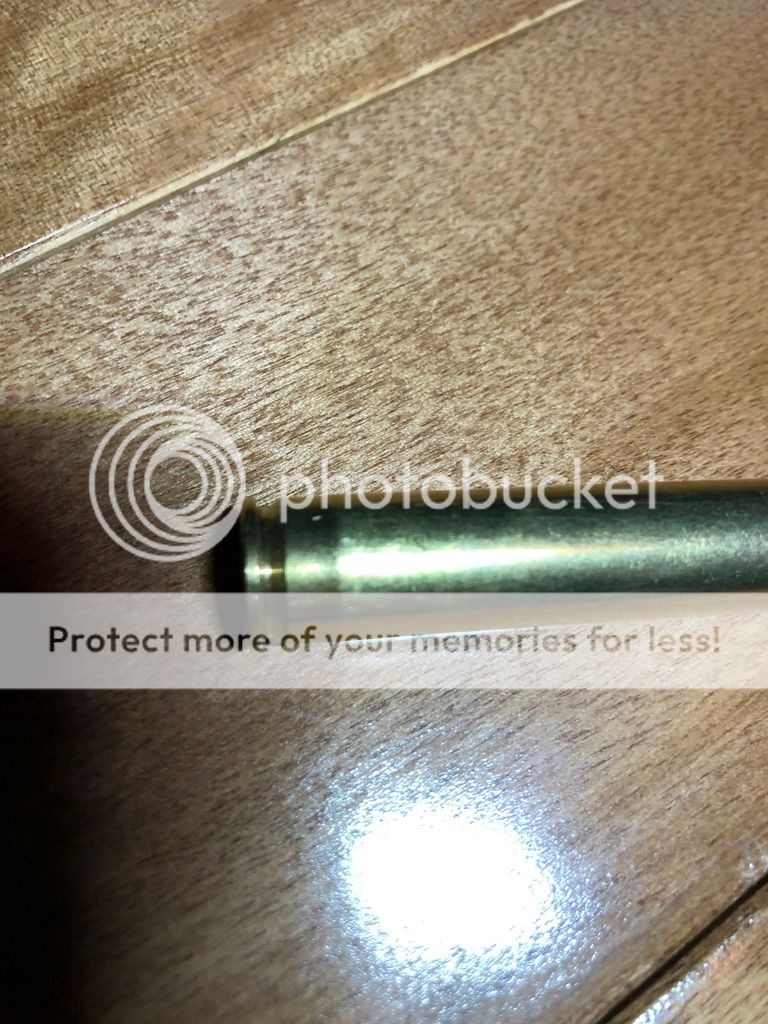

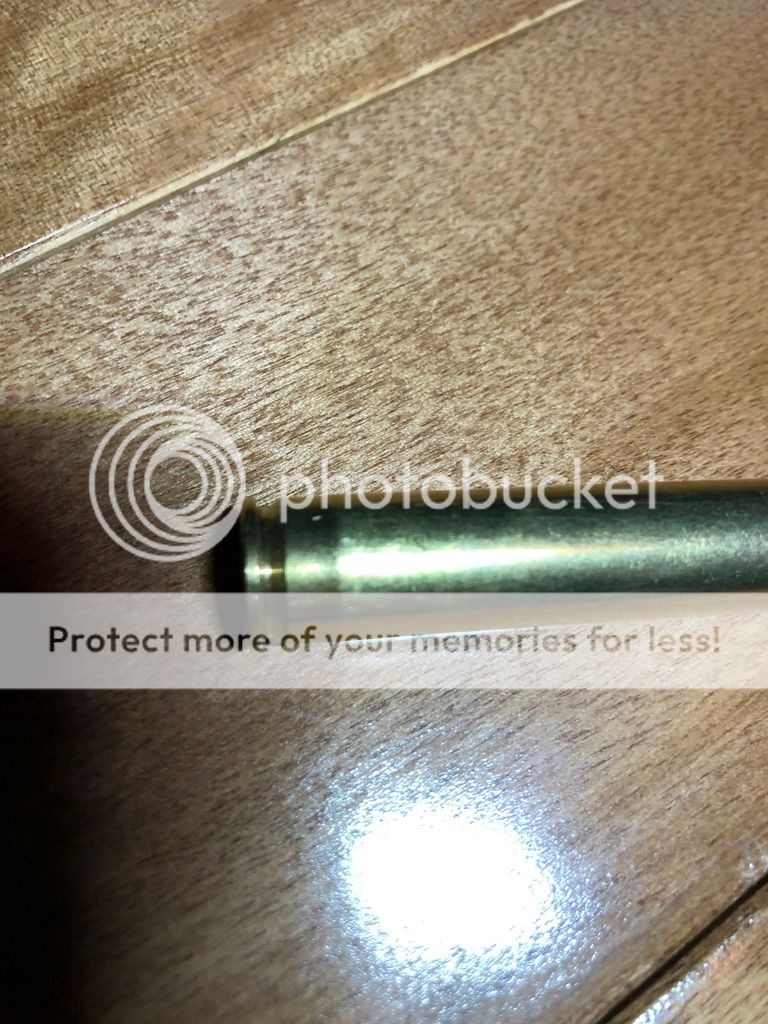

The brass looks as in the pictures below.

Is the shiny part towards the lower end of the brass and / or the Primer condition indication of an issue such as headspace and / or powder load ?

I had checked case length before and after seating the bullets.

Following Lyman 50th Ed instructions.

The cartridges all loaded into my bolt action, but a couple of cases needed a bit of a push. They fired fine and ejected without any issue.

The results were about a 2 inch drop and an inch to the right of centre at 100 yds.

The right of centre could be just me though, I have noticed that I get that result with different rifles and may be down to me flinching or trigger control, especially once I have been through about 50 rds.

On cleaning the rifle I noticed some marks on the bolt face, round circular. The rifle has a couple of hundred rounds through it and this was the first re-loaded ammo I shot in it. Previously it had Barnaul and Federal through it. I can't be 100% sure the markings on the bolt face are new though.

The brass looks as in the pictures below.

Is the shiny part towards the lower end of the brass and / or the Primer condition indication of an issue such as headspace and / or powder load ?

Last edited: