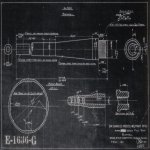

View attachment 498601[/QUOTE]

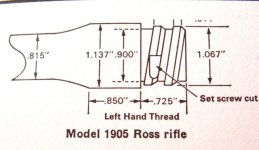

This is an excellent resource for those going forward. It is becoming increasingly hard to find a barrel maker/gunsmith who is comfortable with threading in a barrel for Ross. This should help them! Do you by chance also have one for the 1905 style quick thread?

This is an excellent resource for those going forward. It is becoming increasingly hard to find a barrel maker/gunsmith who is comfortable with threading in a barrel for Ross. This should help them! Do you by chance also have one for the 1905 style quick thread?