Interested in this thread. Been sidetracked but I got a roll of fiberon pet cf17 I earmarked for printing stock on my new Henry. If I come back in a month and there's no tale of plastic splinter in the face man I'll feel very confident doing my project!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

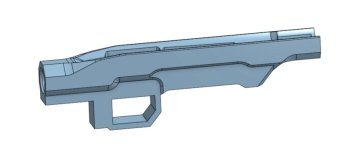

3D Printing R700 Stock

- Thread starter dubious

- Start date

Any tip on maintaining dimensional accuracy while annealing? Not keen on breathing in carbon fiber while post processingPETG-CF and PA6-CF with annealing are 100% up to the strength and heat specs, hell PLA-CF would probably be fine too. The problem is see with making a stock is print volume. Usually capped at 10" unless you have access to really expensive industrial printers.

Slightly talking out my ass up there. I don't know the best way to anneal the PA6-CF.Any tip on maintaining dimensional accuracy while annealing? Not keen on breathing in carbon fiber while post processing

A few months ago I did a deep dive on the strengths of the above mentioned filaments here at work. Along the way we found that PLA-CF surpassed our strength requirements and exceeded my person expectations. We have a few guys at our gun club creating mounts, covers, mag releases, baseplates, and followers out of simple PLA. So the comment of "PETG-CF and PA6-CF with annealing are 100% up to the strength and heat specs" is purely based on the theoretical specs listed here: https://bambulab[DOT]com/en/filament-guide, what others have done, and anecdotal evidence.

That's looking pretty good, did you remix the front to remove the hand guard attachment spot?

I never did download the file pack, what kind of hardware does the build sheet call out?

The design looks like it uses a trapped castle nut for stock mounting, I would want to swap/remix that to picatinny for my purposes.

I'm mostly waiting for you to beta test the magazine system for me

Yeah I didn't want to have multiple pieces, and given my use (10" barrel) I thought it would be more appropriate anyways. I had reached out to the ThingUniverse OP and he got back to me almost instantly with info, and even sent me other STLs related to the project including a super short forend with picatiny rail, but ended up just chopping and merging to get a shorty nose.

The guy also sells the full hardware kit including the action pillars

https://www.hurleywelding.com/product-page/hurleywelding-r700-sa-chassis-hardware-kit

But shipping to Canada is expensive, so just decided to include the pillars into the stock, should be fine given my use (300 blackout). Even out of PLA I think it'll be fine. The print above is in 50% infill, but I've been tweaking the design, and have a bunch of internal parts now around certain areas (pillars, recoil plate, trigger guard, buffer tube) that will be 100% infill in my next print.

I've got a Bergara 6.5 so I might through it in just for fun and see how the stock manages. I might also do some destructive testing on the original one I printed just to see how strong it is

For the Mag I need to order roll pins and find some springs, but quick testing seems to be positive...

Following. I've been looking for a reason to buy a 3d printer. - dan

Last edited:

Depending on the price I'm interested!Still need a bit of hardware, but it's coming together! Y'all think anyone is interested in buying some of these? I'm thinking about ordering hardware but it only comes in bulk... I'll also be adding a front swivel sling stud for a sling / bipod...View attachment 958517

Cool, thanks. Didn't thinked about that.Would like to try this out but, my printer as 220x 220 x 250mm height...

Don't think I could trim this model to fit.

What is your printer size?

I ordered the hardware and a bunch more PLA including supports so I don't have all the defect from the supports. I'll probably print a few and sell them off for pretty cheap ($50+shipping?) just to help me break even.

Think I might start a new design of my own, this ones was a mess because I had to build it from an STL, so lot's of just adding planes and modifying one surface at a time. Might copy the MDT chassis

Think I might start a new design of my own, this ones was a mess because I had to build it from an STL, so lot's of just adding planes and modifying one surface at a time. Might copy the MDT chassis

Last edited:

Keep us appraised of how it goes. Very interesting topic. - danI ordered the hardware and a bunch more PLA including supports so I don't have all the defect from the supports. I'll probably print a few and sell them off for pretty cheap ($50+shipping?) just to help me break even.

Think I might start a new design of my own, this ones was a mess because I had to build it from an STL, so lot's of just adding planes and modifying one surface at a time. Might copy the MDT chassis

These needs to be rounded on top to fit the rounded receiver.

Could be done with sand paper wrap on an appropriate size wood dowel.

Any updates on this project? I just unpacked an Elegoo Centauri Carbon printer, so I'm dangerous now...Also, update on the new design, still need to work on the handle mount and the mag release

View attachment 966473

Mark