300WSM, Norma brass, H4350 and 175gr LRX

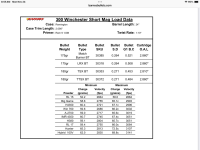

I worked up a load for the 175gr and followed the recommended starting and max load for h4350. I ended up with 66.8gr which was a pretty solid group (3 touching at 100yrd) but I noticed my brass had a little crack in it after an elk hunt. I never used this Norma brass with my previous load so not sure if that is the issue or if I am in fact overpressure even though I am under the Barnes 'Max'. I dropped the load down to 66.6gr to see if the cracks would go away and they are still present in some of the spent cases. The bolt is easy to lift up and I can't see any other signs of overpressure. Also the cracks only appear in 1 of every 3-5 shots.

My average vel is 3074fps but that is from a cheaper chrono and not a garmin.

thoughts?

I worked up a load for the 175gr and followed the recommended starting and max load for h4350. I ended up with 66.8gr which was a pretty solid group (3 touching at 100yrd) but I noticed my brass had a little crack in it after an elk hunt. I never used this Norma brass with my previous load so not sure if that is the issue or if I am in fact overpressure even though I am under the Barnes 'Max'. I dropped the load down to 66.6gr to see if the cracks would go away and they are still present in some of the spent cases. The bolt is easy to lift up and I can't see any other signs of overpressure. Also the cracks only appear in 1 of every 3-5 shots.

My average vel is 3074fps but that is from a cheaper chrono and not a garmin.

thoughts?