You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Challenge - Guess That Brass!

- Thread starter Re3iever

- Start date

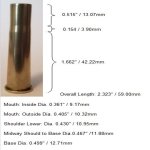

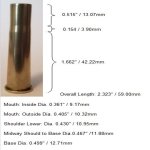

this is a tough one but I think someone tried to make some 43 mauser brass. the numbers are a bit off but very close to 43 mauser

These have been fired in their current configuration and the neck diameter .405" is much smaller than Mauser .465"

- Location

- Western Manitoba

I no longer have 45-70 reloading stuff to measure, but if the nose of neck expander enters can be re-sized back to 45-70 easily enough. Else might need to use the COW method to blow them back out. Likely help if you can anneal them first - else might loose a small percentage without annealing.

vagrantviking

CGN Ultra frequent flyer

- Location

- Southern Alberta

My first thought was 33 WCF but Ruger's numbers are a better match.

Unless you really need to convert back to 45-70 I'd look for a buyer. Someone would be excited to get those. They've been stretched a bit so might have thin necks or fail quickly as 45-70.

Unless you really need to convert back to 45-70 I'd look for a buyer. Someone would be excited to get those. They've been stretched a bit so might have thin necks or fail quickly as 45-70.

Wonder if it maybe for 11x60 necked down cartridge.

https://en.wikipedia.org/wiki/11×60mm_Mauser

Specifications 11x60

Bullet diameter .446 in (11.3 mm)

Neck diameter .465 in (11.8 mm)

Shoulder diameter .510 in (13.0 mm)

Base diameter .516 in (13.1 mm)

Rim diameter .586 in (14.9 mm)

Case length 2.37 in (60 mm)

https://en.wikipedia.org/wiki/11×60mm_Mauser

Specifications 11x60

Bullet diameter .446 in (11.3 mm)

Neck diameter .465 in (11.8 mm)

Shoulder diameter .510 in (13.0 mm)

Base diameter .516 in (13.1 mm)

Rim diameter .586 in (14.9 mm)

Case length 2.37 in (60 mm)

Looks to me like they have been partially (mostly) reformed to .38-70. All that remains is reaming the necks. All externally measured lengths and ODs look good. Pushing the (nominal) 0.015 thick .45-70 necks down to 0.403 OD has made the brass 0.022 thick there resulting in the 0.361 neck ID which is too small. It would have to be reamed to 0.376 or so to finish them up to .38-70 nominal. That might be why they haven't been finished. Just a guess but finding an old die to do the full length resizing might have been easy, but finding a proper reamer to open up the neck ID might not have been? Then again 0.376 is only 0.001 over a 3/8" drill bit so something should have been able to be cobbled up to work and that would end up giving an almost perfect 0.378-0.375 = 0.003/2 = 0.0015 neck tension.

fingers284

CGN Ultra frequent flyer

- Location

- Alberta Cowboy Ranges

My bet would be that someone was trying to make 38-56 using common reloading dies and they just need an expander ball of .375 or so to have a bit of mouth tension.