Morning,

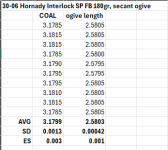

I’ve been trying to zero in on a good load for my 223 and have found a promising combination. I noticed however, that the cartridge lengths seem to float by approximately 0.03” with my set up.

I think this is enough of a difference to make a difference as I can see the spread of my groups change. To improve consistency, is this a matter of one particular piece of equipment’s slop or does this variation signal a host of poor tolerance combinations?

I’ve been using annealed Winchester neck turned brass. I should shell out for premium brass but I’ve been saving that as I continue to tinker. I realize that my thrifty side may be trying to make a silk purse out of a pigs ear but I’ve the time currently to explore my hobby and see how my efforts impact my rifles performance.

I’m using a Hornady LNL Classic single stage press with a Redding set of dies with a micrometer seater, Hornady ELD-M bullets, a Mitutoyo caliper with a Hornady Bullet comparator with a 223 insert to measure. Since the evaluation of the ammunition is on paper and seems to align with the final length measurements, I’m certain that at least the caliper is reliable and dependable.

To remedy this I suppose I could shell out for better equipment and components. I have also simply tried to seat the bullets taller and then incrementally bump them shorter by making minor adjustments to the micrometer. Is the 30 thousandths variation common with other set ups? Is the consistency a matter of improving all the equipment and components or is there a single change which will assist me?

Thank you for sharing your knowledge.

I’ve been trying to zero in on a good load for my 223 and have found a promising combination. I noticed however, that the cartridge lengths seem to float by approximately 0.03” with my set up.

I think this is enough of a difference to make a difference as I can see the spread of my groups change. To improve consistency, is this a matter of one particular piece of equipment’s slop or does this variation signal a host of poor tolerance combinations?

I’ve been using annealed Winchester neck turned brass. I should shell out for premium brass but I’ve been saving that as I continue to tinker. I realize that my thrifty side may be trying to make a silk purse out of a pigs ear but I’ve the time currently to explore my hobby and see how my efforts impact my rifles performance.

I’m using a Hornady LNL Classic single stage press with a Redding set of dies with a micrometer seater, Hornady ELD-M bullets, a Mitutoyo caliper with a Hornady Bullet comparator with a 223 insert to measure. Since the evaluation of the ammunition is on paper and seems to align with the final length measurements, I’m certain that at least the caliper is reliable and dependable.

To remedy this I suppose I could shell out for better equipment and components. I have also simply tried to seat the bullets taller and then incrementally bump them shorter by making minor adjustments to the micrometer. Is the 30 thousandths variation common with other set ups? Is the consistency a matter of improving all the equipment and components or is there a single change which will assist me?

Thank you for sharing your knowledge.

Last edited: