^ looks identical to what I made. I wonder if those lead a gun as bad as mine did. Despite the modest report and recoil, and casting my 000 from water cooled COWW it was pretty bad. When I was still working on it I was going to try sourcing some plated shot. Shipping made it expensive enough that I just moved on though.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Duplex Bullets in a 357

- Thread starter Ganderite

- Start date

Burton Urnie

Regular

- Location

- Near Woodstock New Brunswick

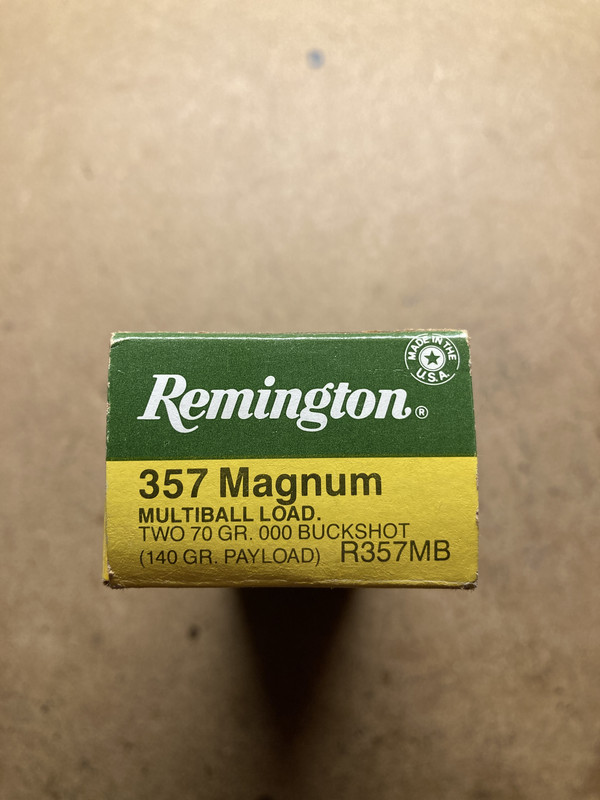

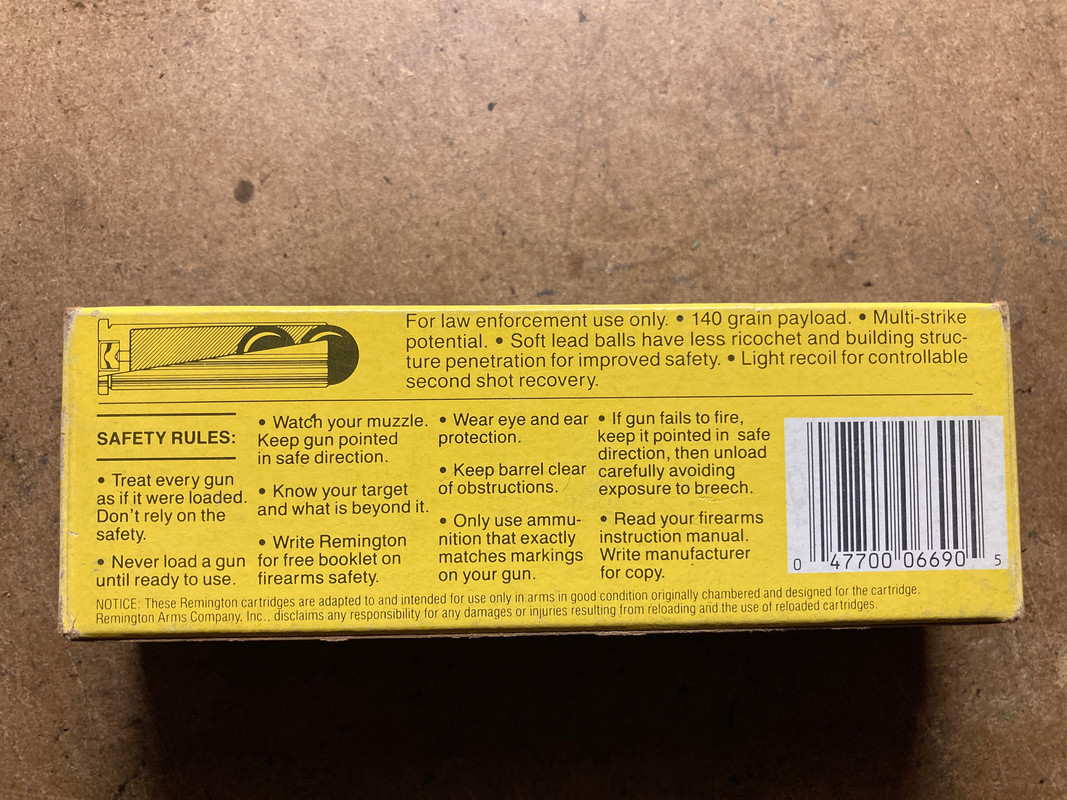

I have a couple boxes of these from years ago, never fired them.

They seemed interesting at the time.

Very cool find!

Here's a trick that's older than any of us:

1. take a mold with at least one driving band in which a gas check will fit. Plain-Base molds produce full-wadcutters, and gas-check molds produce semi-wadcutters;

2. insert a gas check upside-down in the driving band; and

3. pour.

I used the Lyman 358430 (194 gr, 0.360") and produced 96 gr and 66 gr FWC's. You could load two of the 96 gr and three of the 66 gr in a 357 Mag, four 66's in a 357 Max! Beware though that almost all of the bullet will be in the case body, so loads can't simply be for a 200 gr bullet. You can crimp the top bullet just above the gas check leaving 0.100" in the case. The 96 gr is 0.375" in length, and the 66 gr is 0.260". Three 66's would therefore be seated 0.620" into the 357 Mag case, using up about 50% of the available powder space. A powder like H4227, starting at 10.0 grs and stopping at abuot 1200 fps would seem to be a good fit.

1. take a mold with at least one driving band in which a gas check will fit. Plain-Base molds produce full-wadcutters, and gas-check molds produce semi-wadcutters;

2. insert a gas check upside-down in the driving band; and

3. pour.

I used the Lyman 358430 (194 gr, 0.360") and produced 96 gr and 66 gr FWC's. You could load two of the 96 gr and three of the 66 gr in a 357 Mag, four 66's in a 357 Max! Beware though that almost all of the bullet will be in the case body, so loads can't simply be for a 200 gr bullet. You can crimp the top bullet just above the gas check leaving 0.100" in the case. The 96 gr is 0.375" in length, and the 66 gr is 0.260". Three 66's would therefore be seated 0.620" into the 357 Mag case, using up about 50% of the available powder space. A powder like H4227, starting at 10.0 grs and stopping at abuot 1200 fps would seem to be a good fit.

Attachments

Last edited:

Brutus

CGN Ultra frequent flyer

Ganderite. You said here the plated Canpro did not group well with the lead SWC.

I believe it's the incompatibity two different bullet jacket material.

Example: if I shoot zinc jacketed Calhoon bullets in my 222 Remington and I switch back to normal copper jacketed bullets I must clean that barrel of all zinc deposits before shooting copper jacketed bullets.

Otherwise accuracy suffers badly.

I believe it's the incompatibity two different bullet jacket material.

Example: if I shoot zinc jacketed Calhoon bullets in my 222 Remington and I switch back to normal copper jacketed bullets I must clean that barrel of all zinc deposits before shooting copper jacketed bullets.

Otherwise accuracy suffers badly.

You can also buy the Speer shot capsules and put three .30 cal buckshot inside the capsules. In a revolver, if you pull the trigger six times you will have 18 holes in the target.

You can also cut brass brazing rod down to fit in the capsules and make your own flechette rounds.

You can also cut brass brazing rod down to fit in the capsules and make your own flechette rounds.

Ganderite. You said here the plated Canpro did not group well with the lead SWC.

I believe it's the incompatibity two different bullet jacket material.

Example: if I shoot zinc jacketed Calhoon bullets in my 222 Remington and I switch back to normal copper jacketed bullets I must clean that barrel of all zinc deposits before shooting copper jacketed bullets.

Otherwise accuracy suffers badly.

The CamPro bullets are 355, not 357, so may not be a real good choice. The pair of 357 SWC shot very well, all the way to 25 yards. The 95gr .355 bullet would only be good for close range anti-social shooting.

I did some testing of that. see below.

I loaded up all the 115 SWC bullets I had on hand as duplex loads in 357.

I had a few more cases to go in that 50 round box, so experimented with some 130 gr lead round nose bullets on top of the 95 gr 9mm CamPros. I knew these would not stick together at 25 yards, but tested them at 15 yards.

Good enough.

Since I have lots of these 130 gr lead bullets and lots of 9mm CamPros, I decided to do some duplex testing of 38Spl.

I tried some 130 Lead on top of CamPro. These worked with the stiffest load I cared to try - 7.4 gr of 2400 for 840 fps.

I also tried a pair of the plated 95 gr CamPros. Velocity was way down. Might have been some blow-by with that undersized bullet. I gave up on that.

The 130 lead RN on top of a CamPro seemed to work well.

I had a few more cases to go in that 50 round box, so experimented with some 130 gr lead round nose bullets on top of the 95 gr 9mm CamPros. I knew these would not stick together at 25 yards, but tested them at 15 yards.

Good enough.

Since I have lots of these 130 gr lead bullets and lots of 9mm CamPros, I decided to do some duplex testing of 38Spl.

I tried some 130 Lead on top of CamPro. These worked with the stiffest load I cared to try - 7.4 gr of 2400 for 840 fps.

I also tried a pair of the plated 95 gr CamPros. Velocity was way down. Might have been some blow-by with that undersized bullet. I gave up on that.

The 130 lead RN on top of a CamPro seemed to work well.

I found them on my shelf. had them for about 40 years. I think a buddy cast them. He used to shoot them in his basement range.

If I was keen I could find the mold and cast more. I have 100 lbs of Linottype sitting here.

If I was keen I could find the mold and cast more. I have 100 lbs of Linottype sitting here.