For they that are interested.

The PRIME CONTRACTORS of the MP40 were;

- Erma Erfurter Machinenfabrik B.Geipel Gmbh, Erfurt; Early MP38/MP40 code:"27", late code: "ayf".

- Steyr Daimler Puch, A.G.Werk, Steyr, Austria; early code:"660", late code:"bnz".

- C.G.Haenel, Waffen-u Fahrradfabrik, Suhl; Early code:"122", late code:"fxo".

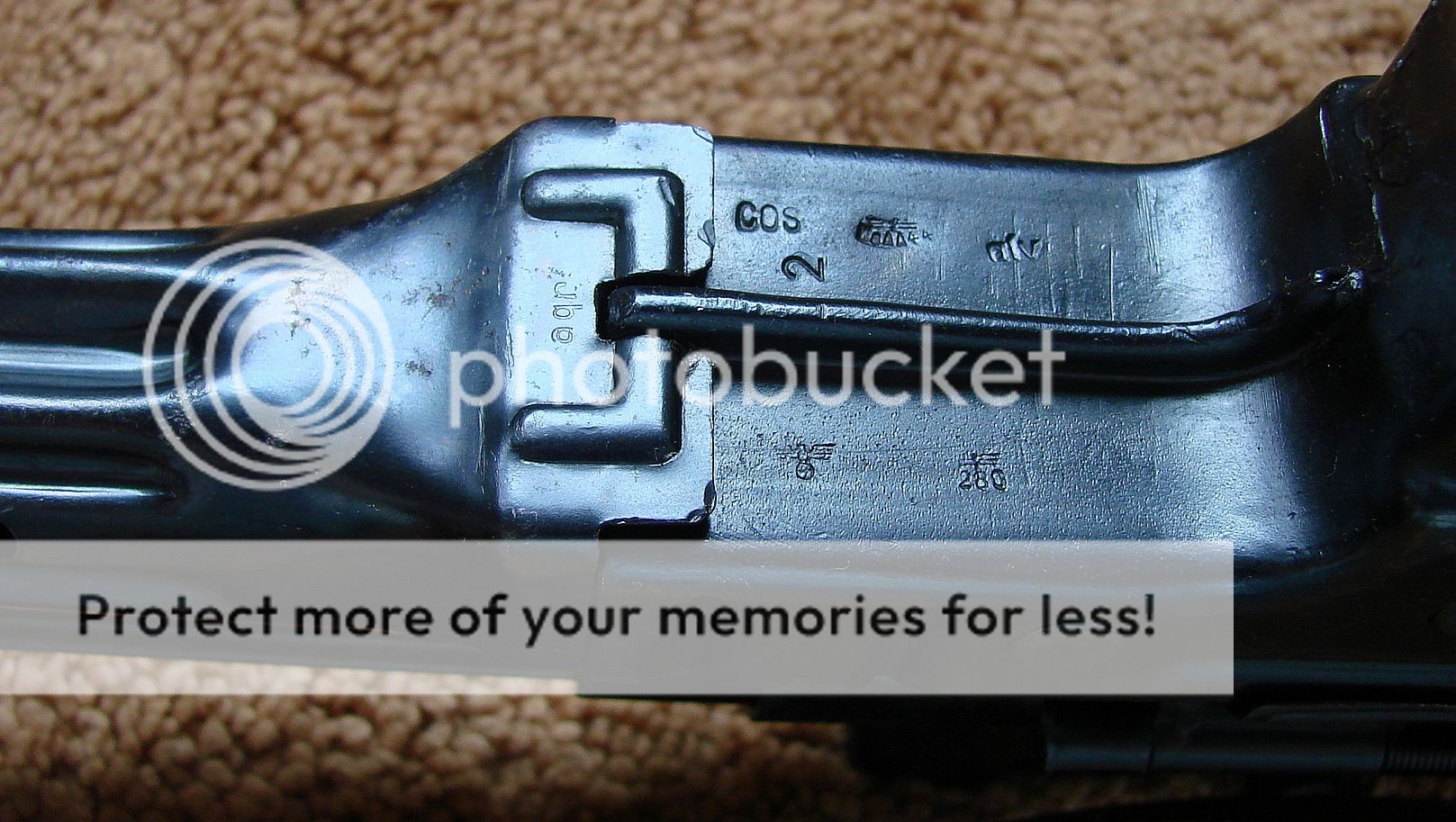

The SUBCONTRACTORS that furnished the MP40's PRIME CONTRACTORS with parts and subassemblies stamped their (subcontractor's) letter codes and inspector's Waffenamt-marks on the parts that they supplied. The parts were then shipped to the PRIME CONTRACTOR'S factory for assembly.

SUBCONTRACTORS OF PARTS AND SUBASSEMBLIES:

- Gebrueder Merz, Werz Werk, Frankfurt, Main; "cos".

- National Krupp Registerierkassen, GmbH, Berlin; "cnd".

-Steyr-Daimler Puch AG Werk Graz; "kur".

In 1943, the total production of MP40s was 234,311 guns, which included total allocation to the Heer, Luftwaffe, and Kreigmarine.

The gun had a cyclic rate of fire of approximately 500 RPM utilizing an open bolt action, and was reputed to be one of the most reliable, accurate, and effective submachine guns of the Second World War. The slower rate of fire resulted in better shooter control when compared to many of the other sub-guns of this period.

The MP40 magazines were made of formed sheet metal, as was the follower, and had a normal maximum 32 round capacity of 9mm Parabellum ammunition. The magazine was a double-stack, single-feed design. Shown below is one of the later more common examples of this magazine, marked MP38u.40.

Manufacturers of MP40 magazines, their codes, and common Waffenamt-Marks are indicated below:

-"kur 98e”, Steyr,Warsaw. WaA815

-"ayf", Erma Werk, WaA280

-"kur",Steyr, WaA815

-"bte", Frankisch Eisenwerk, WaA839,WaA088

-"gqm", Loch & Hartenberger ,WaA164,WaA54,WaA98

-"fxo", Heanel, WaA387,eagle 37

-"122", Haenel (early), WaA280, WaA387, eagle/#37

-"MP41", Haenel, H enclosed in a circle.

-Steyr-Daimler Puch AG Werk Graz; "kur".

This MP40 was assembled by Erma-Werke--- code 'ayf' in 1943.

Some examples of MP40 magazine markings.

The PRIME CONTRACTORS of the MP40 were;

- Erma Erfurter Machinenfabrik B.Geipel Gmbh, Erfurt; Early MP38/MP40 code:"27", late code: "ayf".

- Steyr Daimler Puch, A.G.Werk, Steyr, Austria; early code:"660", late code:"bnz".

- C.G.Haenel, Waffen-u Fahrradfabrik, Suhl; Early code:"122", late code:"fxo".

The SUBCONTRACTORS that furnished the MP40's PRIME CONTRACTORS with parts and subassemblies stamped their (subcontractor's) letter codes and inspector's Waffenamt-marks on the parts that they supplied. The parts were then shipped to the PRIME CONTRACTOR'S factory for assembly.

SUBCONTRACTORS OF PARTS AND SUBASSEMBLIES:

- Gebrueder Merz, Werz Werk, Frankfurt, Main; "cos".

- National Krupp Registerierkassen, GmbH, Berlin; "cnd".

-Steyr-Daimler Puch AG Werk Graz; "kur".

In 1943, the total production of MP40s was 234,311 guns, which included total allocation to the Heer, Luftwaffe, and Kreigmarine.

The gun had a cyclic rate of fire of approximately 500 RPM utilizing an open bolt action, and was reputed to be one of the most reliable, accurate, and effective submachine guns of the Second World War. The slower rate of fire resulted in better shooter control when compared to many of the other sub-guns of this period.

The MP40 magazines were made of formed sheet metal, as was the follower, and had a normal maximum 32 round capacity of 9mm Parabellum ammunition. The magazine was a double-stack, single-feed design. Shown below is one of the later more common examples of this magazine, marked MP38u.40.

Manufacturers of MP40 magazines, their codes, and common Waffenamt-Marks are indicated below:

-"kur 98e”, Steyr,Warsaw. WaA815

-"ayf", Erma Werk, WaA280

-"kur",Steyr, WaA815

-"bte", Frankisch Eisenwerk, WaA839,WaA088

-"gqm", Loch & Hartenberger ,WaA164,WaA54,WaA98

-"fxo", Heanel, WaA387,eagle 37

-"122", Haenel (early), WaA280, WaA387, eagle/#37

-"MP41", Haenel, H enclosed in a circle.

-Steyr-Daimler Puch AG Werk Graz; "kur".

This MP40 was assembled by Erma-Werke--- code 'ayf' in 1943.

Some examples of MP40 magazine markings.

Last edited: