You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Feeding a 45-70

- Thread starter The Suisider

- Start date

- Location

- British Canuckistan

yes it does, only so much powder will stick to the surface and when it "melts" it creates a very uniform coating

and by melt...you mean once it's been fired or during a portion of the application? I thought there was a post about how it was done, but I'm not seeing it now...so how do you coat them in powder? does it involve heat?

and by melt...you mean once it's been fired or during a portion of the application? I thought there was a post about how it was done, but I'm not seeing it now...so how do you coat them in powder? does it involve heat?

The dry powder is sprayed on the lead bullets where it "clings" electrostatically (think static cling). The bullets with the dry powder are then put in a low-temperature oven and heated to the point where the plastic powder melts and flows evenly over the bullet. The temperature used is lower than the melting temperature of the lead alloy used to cast the bullets.

and by melt...you mean once it's been fired or during a portion of the application? I thought there was a post about how it was done, but I'm not seeing it now...so how do you coat them in powder? does it involve heat?

https://www.canadiangunnutz.com/forum/showthread.php/1240412-Powder-Coating

vagrantviking

CGN Ultra frequent flyer

- Location

- Southern Alberta

and by melt...you mean once it's been fired or during a portion of the application? I thought there was a post about how it was done, but I'm not seeing it now...so how do you coat them in powder? does it involve heat?

https://www.canadiangunnutz.com/forum/showthread.php/1240412-Powder-Coating

Beat me to it!

unstableryan

CGN Ultra frequent flyer

- Location

- Beautiful Okanagan Valley

In the beginning, I bought one box of leverevolution rounds because I had to shoot it before the dies came in. They are ok, but I don't like them and the brass is shorter than normal and not as good as any other brass. I have a huge bag of them that non-reloaders have given me because they know I'm a 45/70 guy. I have played with making them into small game shot shells, etc with mixed success.

I do also have about 400 brass that are probably on their 4th to 6th reload. I started buying bullets and loading, then buying cast bullets and loading and now casting bullets, powdercoating and loading. I would hunt nearly anything with a hard cast 340 or 405 at 1300-2000 fps.

I can get it down to about 12 cents a round using unique/trail boss and home cast and they would still kill a deer like the old black powder rounds killed bison. I'm not factoring propane or electricity for the pot, or my time, but when I can go out and blast of 50 and not feel a bit bad about it, it's worth it. Even my loads at 1500-1800 are more like 30 cents a round. Buy cheap, stack deep.

Reload at first to make it cheaper, then you realize you can make it more versatile, then after a while you realize you can make them better.

I do also have about 400 brass that are probably on their 4th to 6th reload. I started buying bullets and loading, then buying cast bullets and loading and now casting bullets, powdercoating and loading. I would hunt nearly anything with a hard cast 340 or 405 at 1300-2000 fps.

I can get it down to about 12 cents a round using unique/trail boss and home cast and they would still kill a deer like the old black powder rounds killed bison. I'm not factoring propane or electricity for the pot, or my time, but when I can go out and blast of 50 and not feel a bit bad about it, it's worth it. Even my loads at 1500-1800 are more like 30 cents a round. Buy cheap, stack deep.

Reload at first to make it cheaper, then you realize you can make it more versatile, then after a while you realize you can make them better.

nowarningshot

CGN Ultra frequent flyer

This has certainly turned out to be an informative thread!

Does powder-coating produce consistent thickness of coating on the bullets? Interesting idea.

One further point.

When powder coated, you still need to size them. Most likely a lee press mounted through die. But you can run them in your lubersizer without lube

Another thread running right now on Hornady ftx bullets. Personally im not a fan. Running a smaller bullet isn't turning a 45/70 into a 270. The old trapdoor load was i believe 405 bullet at 12 or 1300ft/sec. Basically a 22lr velocity, for a bullet 10x the size. Under a hundred yards, kills by a large initial hole and penetrating vs hydrostatic shock with bottlenose cartridges. Modern rifles can push well past trapdoor, 1800-2000 and more. Some claim to be able to push towards 458win mag performance. Imagine that hurts on both ends.

unstableryan

CGN Ultra frequent flyer

- Location

- Beautiful Okanagan Valley

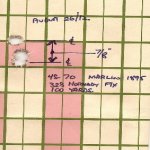

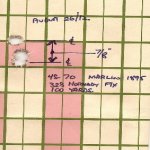

I usually size 9mm and .357 bullets after powder coating. My microgroove marlin 45/70, i usually just coat and load. Works for me.