Two most important aspects of gunsmith screwdriver are modifiable tip and improve torque transfer handle.

Blades are usually two sided and can be made out of almost any material needed/available at time. I will try to find a pic online.

In the mean time these from LeeValeey are almost perfect. They have wider handles and parallel tip with burnisher. This allows tip to grab screw at the bottom of the screw slot preventing slippage. With these long necks they are modifiable for years to come.

Real thing:

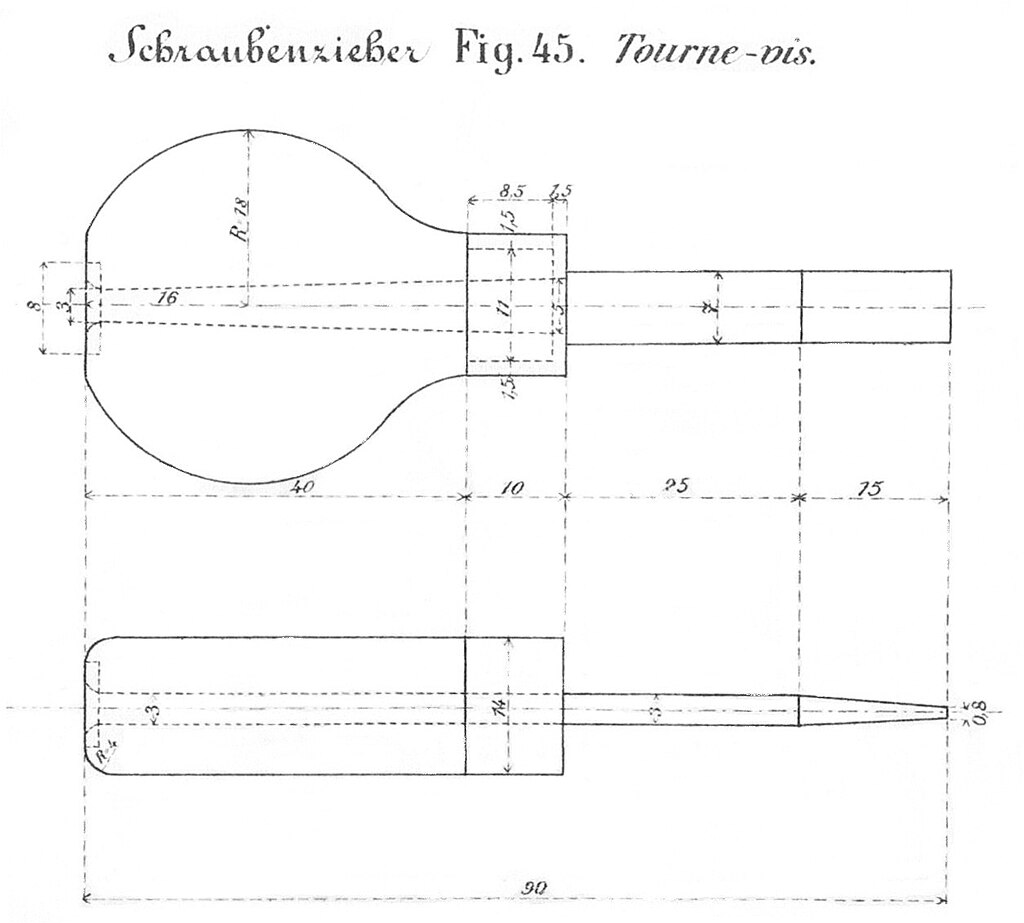

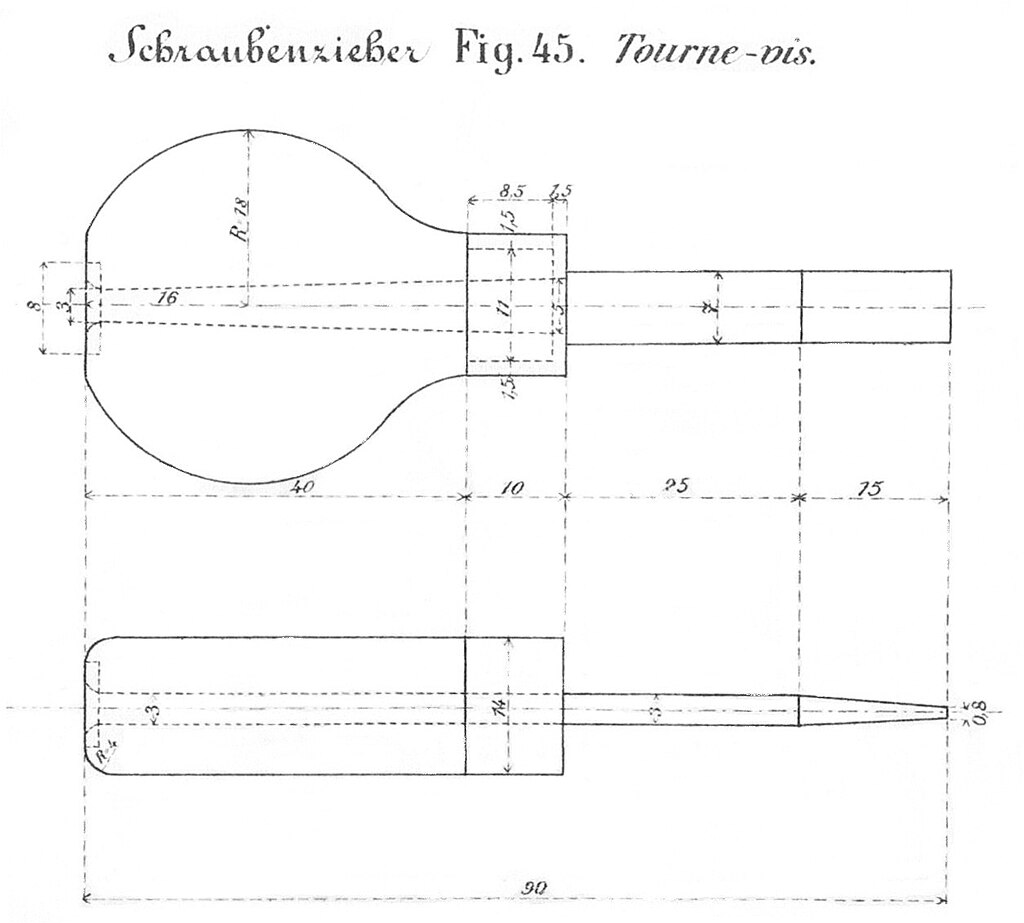

For those who would like to make their own here is blueprint for simple one.

Blades are usually two sided and can be made out of almost any material needed/available at time. I will try to find a pic online.

In the mean time these from LeeValeey are almost perfect. They have wider handles and parallel tip with burnisher. This allows tip to grab screw at the bottom of the screw slot preventing slippage. With these long necks they are modifiable for years to come.

Real thing:

For those who would like to make their own here is blueprint for simple one.

Last edited: