As the bullets get heavier the powder used is reduced to keep the peak pressure under control. So using 158gn data isn't a good idea.

You say you have Titegroup. Well Hodgdon makes Titegroup and Hodgdon has an online reloading data center

http://www.hodgdonreloading.com/

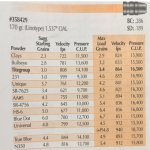

And if you navigate to the 38Spl loads you'll find that there is data for a 170 gn option. And if you compare the loads for Titegroup between 158 and the 170 you'll see that the max for 158 is 3.8 and the max for 170 is 3.6. And even that slight difference causes the pressure for the 170 to be higher than for the 158. If you're loading 177's I'd tend to go even lighter than 3.6 as a max. Based on the .2 grain difference seen in this change for 177's I'd be inclined to consider 3.4gns of Titegroup as a maximum. And even with that I'd want to sneak up on the 3.4gns inspecting the primers closely for any signs of pressure forming in the pockets of the casings. It's one thing for .357's to square up the edges of the primers but we really do not want to see that in a .38 Special. Particularly if it's a snub nose that is specifically chambered for .38Spl and not really rated even for +P.