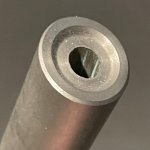

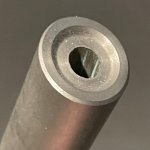

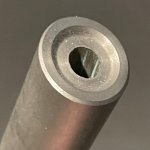

I would guesstimate that was a bead blasted, likely stainless of some kind, barrel blank that was set up for something with a separate recoil lug - like Remington 788 or Remington 700. For someone to want to "screw it in", you would likely want fairly accurate dimensions of those barrel tenon threads - external diameter and threads per inch, plus probably length of the threaded area. Some barrels like that may simply screw in snug and headspace appropriately - other barrels like that might take some fussing to get headspace, bolt face clearance, etc. to match up with any particular bolt and receiver. It appears to be more or less "straight" "tapered" profile, so if it was to replace a "skinnier" barrel, would likely need to scrape out the existing stock barrel channel for it to fit and clearance. My guess, anyway.

Your second picture shows what might be a serial number - suggesting that might be a factory take-off barrel, but they usually will have the maker's logo, also. Someone else may recognize that number series - I do not.

Would be more common, I think, to start with a rifled barrel blank - and a receiver with bolt - then measure and turn the tenon threads to fit that receiver, and chamber to headspace for that receiver and bolt. But sometimes can "get away" with using one that was set up for another rifle that is similar. It would surprise me, for example, if all Remington 700 receivers and bolts were precisely the same - but many are likely "close enough".

I have a "long chambered" McGowan barrel here, in 257 Roberts. It screws on snug to a Mauser 98 receiver, but barrel tenon is too long, so bolt won't close. That barrel nominally chambered 0.030" too deep - so idea was that one can peel off from rear end of barrel, peel off from barrel shoulder - to get to appropriate head space and bolt face clearance.

Your second to last picture is showing some blue/green streaks along the side of some rifling - as if that barrel had been fired - then some copper jacket material never cleaned out - and has since corroded. I am not sure. You do not see that on "new" or "clean" rifled barrels. There might or might not be markings on the very rear end of that barrel - around the chamber entrance - under that black crud - likely some solvent will dissolve and clean that stuff off? - is typical that the rifling twist rate is stamped on end of rifled barrel blank - that might still be there.

That "possibly" previously fired thing might be important - goes to the condition of the lands and freebore area in that barrel - I do not know how to look at that, except with a bore scope - must be other ways to do so, though. If that was a "home done" thing, might be concerned about whether that chamber is actually concentric with the bore, or not. That may or may not be of concern.