Ok and powder coating how toxic is that as melting lead is gonna take some PPE but the casting is that gonna require ventilators aswell?Yes, whereabouts are you? as with all things reloading associated a close by mentor that has "been there done that" can save a fistfull of dollars and casting is one of the things that folks have been trying to perfect for 150 yrs and frustration kills a lot of enthusiasm for the operation before a lot of people realize any success.

i will offer up two things that made casting a very viable part of my shooting world....the other casting bible forum- Castboolits is invaluable to a starter...plan on reading for a few hours but will save days of frustration

...and Powder coating make it all worthwhile, almost daily I thank Augie Doggy for introducing me to PC'ing over 10 yrs ago...it just make the whole operation worth while.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help getting started

- Thread starter Milsurp26

- Start date

You won't get lead fumes until past 900° or so, which is WAY too hot for casting. Most of the nasy smelling stuff is crap off of the wheel weights ( if that's what you are using) like oil, old coolant and general road grime. Lead pipe has whatever was flowing through it and roof flashing will probably have lots of icky tar. Cotton clothing, leather boots, welding gloves and a full face shield are good ideas when handling molten alloy just in case the tinsel fairy (dragon actually) makes an appearance. Avoid synthetic clothing.

Some powder coat powders are TGIC based, which can be nasty, so some sort of fume hood over your toaster oven is a good idea. Nitrile gloves and an N95 mask are fine when coating the cast bullets. Nothing is needed after the PC'd bullets are baked and cooled.

Auggie D.

Some powder coat powders are TGIC based, which can be nasty, so some sort of fume hood over your toaster oven is a good idea. Nitrile gloves and an N95 mask are fine when coating the cast bullets. Nothing is needed after the PC'd bullets are baked and cooled.

Auggie D.

I have been casting for several calibers for a long time. Just started powder coating last winter. I see now that’s the way to go. I use LEE bottom pour pots and almost all LEE molds. I just bought a mold for my .32WS and 8x57 rifles from Arsenal. I always enjoy casting and the added step of powder coating is a pleasure also. I use wheel weights and sometimes a bit of linotype added. I recently bought a .22 caliber gas check maker. Another rabbit hole.

Yes, I agree. Yet another hole, to pour money into. Started casting for 41 swiss, next came the .311 setup for SKS SVT & 303 Brit. Today I got my .308 dia 170 gr flat nose for 30.30. New tires getting mounted tomorrow, so I'll try throwing some of those, while I'm without my veh. As a bonus I asked for and received permission to grab the used lead WW in their scrap bucket.

quinnjoblow

CGN Regular

- Location

- East of Toronto

I just use a single burner electric hotplate( bought it new at NoFrills for $15) and an old stainless steel pot to process my lead. Keep it at a low simmer and stir occasionally. Just like my Kraft dinner

Wheel weights work very well on their own. While not especially hard, they cast fairly well and with powder coating, their performance level is extended. An extra bit of tin can be helpful in Loverin style bullets with lots of grooves. These bullets also like lots of heat.Are you folks typically adding 50/50 solder to the wheel weights? What are your thoughts on straight 16:1 or 20:1 if used in mild loads in a rifle?

You can, but would be a waste of the 50/50.Are you folks typically adding 50/50 solder to the wheel weights? What are your thoughts on straight 16:1 or 20:1 if used in mild loads in a rifle?

@ 20:1 you gain 0.1 Brinell

@ 16:1 you gain 0.2 Brinell

The tin in the 50/50 would be more useful for other applications. Tin's main purpose is to reduce the surface tension of the lead to help with mold fill out.

20:1 COWW

| Tin % | Antimony % | Arsenic % | Copper % | Silver % | Lead % | Weight | Est. Hardness |

| 2.86% | 2.86% | 0.24% | 0.00% | 0.00% | 94.0% | 21.0 | 12.1 |

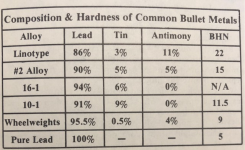

I was reading through my old Lyman "Cast Bullet Handbook" and it gives this information:You can, but would be a waste of the 50/50.

@ 20:1 you gain 0.1 Brinell

@ 16:1 you gain 0.2 Brinell

The tin in the 50/50 would be more useful for other applications. Tin's main purpose is to reduce the surface tension of the lead to help with mold fill out.

20:1 COWW

Tin % Antimony % Arsenic % Copper % Silver % Lead % Weight Est. Hardness 2.86% 2.86% 0.24% 0.00% 0.00% 94.0% 21.0 12.1

I was asking about the 50-50 because I thought it would make the casting process easier. I have access to "pure" lead and to wheel weights and, like the OP, trying to sort out what I need. This is also from the same book:

And this doesn't make sense to me as per the previous chart #2 alloy has 5% antimony. WW have 4% and 50/50 has none. And adding 1 pound of 50/50 for every 9 pounds of WW can become expensive.

Last edited:

I was reading through my old Lyman "Cast Bullet Handbook" and it gives this information:

View attachment 877218

I was asking about the 50-50 because I thought it would make the casting process easier. I have access to "pure" lead and to wheel weights and, like the OP, trying to sort out what I need. This is also from the same book:

View attachment 877221

And this doesn't make sense to me as per the previous chart #2 alloy has 5% antimony. WW have 4% and 50/50 has none. And adding 1 pound of 50/50 for every 9 pounds of WW can become expensive.

Wheel weight composition is different for each manufacturer and has changed over time

Values I use are from an X-ref sample

Go find yourself a pewter mug at a benevolent fund or goodwill, usually $3-5 ( I have found some as low as $1)

20:1 COWW/pewter

| Tin % | Antimony % | Arsenic % | Copper % | Silver % | Lead % | Weight | Est. Hardness |

| 4.88% | 3.14% | 0.24% | 0.07% | 0.00% | 91.7% | 21.0 | 12.9 |

want more hardness? water quench themThanks for the information!

To be perfectly honest I don't know if I do. I am just starting out - waiting for various stuff to arrive. Will start with mild loads for .44 Mag/SPL and 45 Colt - both for rifles. So mild loads for plinking - just want to avoid leading as much as possible. I understand hardness is a factor and I also may try poly shot buffer with a hole punched piece of copy paper between the powder and buffer. I spoke with a fellow who said that works very well for him.want more hardness? water quench them

Last edited: