So I’ve finally got the bits and pieces that I need to try removing the factory barrel from my Tikka T3 Varmint. I’ve watched a couple of YouTube videos out there for suggestions and thought I was good to go.

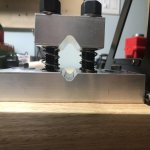

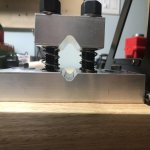

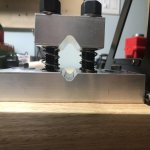

I put the barrel in my barrel vice and immediately ran into what I suspected would be a problem. I bought the barrel vice here on CGN. You can see from the pictures that the barrel channel isn’t really round. I used some drywall tape (YouTube video suggestion) and clamped my barrel into the vice. A combination of the barrel taper and the edges on the barrel channel resulted in a spinning barrel and some scuff marks on my barrel to boot. Any suggestions on how to get a better bite / more friction to keep the barrel from spinning?

Here are some pics of my setup if that helps.

I put the barrel in my barrel vice and immediately ran into what I suspected would be a problem. I bought the barrel vice here on CGN. You can see from the pictures that the barrel channel isn’t really round. I used some drywall tape (YouTube video suggestion) and clamped my barrel into the vice. A combination of the barrel taper and the edges on the barrel channel resulted in a spinning barrel and some scuff marks on my barrel to boot. Any suggestions on how to get a better bite / more friction to keep the barrel from spinning?

Here are some pics of my setup if that helps.

Attachments

-

07D2D41D-FA7B-49F1-88C0-72F4683222C0.jpg62.3 KB · Views: 706

07D2D41D-FA7B-49F1-88C0-72F4683222C0.jpg62.3 KB · Views: 706 -

461FD26A-252B-497B-BE9F-EB66F950EAEB.jpg53.5 KB · Views: 706

461FD26A-252B-497B-BE9F-EB66F950EAEB.jpg53.5 KB · Views: 706 -

BDC9E53A-20CB-49CB-9F56-FFC7B0F50352.jpg32.9 KB · Views: 703

BDC9E53A-20CB-49CB-9F56-FFC7B0F50352.jpg32.9 KB · Views: 703 -

2C48FC45-A7CD-4643-A1AB-F189335E162F.jpg42.9 KB · Views: 704

2C48FC45-A7CD-4643-A1AB-F189335E162F.jpg42.9 KB · Views: 704 -

5CC6B9B4-22D2-43E9-AC8A-46278CE09E49.jpg59.7 KB · Views: 704

5CC6B9B4-22D2-43E9-AC8A-46278CE09E49.jpg59.7 KB · Views: 704