You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How bad is my Bore?

- Thread starter RP22

- Start date

Blastattack

CGN Ultra frequent flyer

- Location

- Winnipeg MB

How does it shoot? If it shoots well, then the condition is irrelevant.

Alright after 5 days of cleaning I finally have a pretty clean bore. There are still a few copper streaks and bit of a carbon ring but it is a vast improvement from where I started.

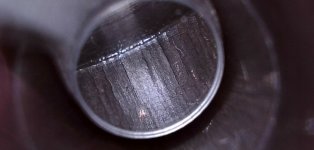

For reference, Here is the as found bore.

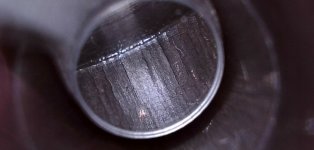

And here is the as left bore after cleaning.

Here was my process.

The comment about getting the barrel HOT really intrigued me so using a funnel I poured a full kettle of boiling water down the barrel and got it very hot, too hot to touch. then a patch of hoppes (I don't recommend hoppes but it is the solvent I have on hand), then went at it with a bronze brush. I really think the heat helped here, there was so much crap coming out the brush was frothy. Then patched all that crap out with hoppes. Then a shot of wipe out down the barrel and left it for approx 12 hours.

The next morning I patched out the wipe out and got very blue patches. Another shot of wipe out and another 12 hours.

I did 4 rounds of Wipe out, checking progress with the scope every time. Copper was certainly being removed.

After the 4th round I went in with a bronze brush again to hit the carbon, patching out again with hoppes.

Then another 2 rounds of wipe out.

By this time the JB Bore Paste and Kroil had arrived. I followed the instructions and did 10 full barrel passes with a patch wrapped bronze brush. Then flushed out with hoppes. As you might expect this really got the remaining copper to move and the throat was getting shiny too. I did 10 more full passes with the JB and called the barrel good.

After that I just went after the carbon ring with JB and patches wrapped around an over sized brush.

Conclusions:

Wipe Out is fantastic. I'm sure the other copper solvents I tried were working but Wipe Out is so easy and safe. I'll be using this exclusively from now on.

Hoppe's 9 - I basically used hoppes here as a flushing agent and tried to use it up. Not going to be buying more.

Heated Barrel - Seems to help, shouldn't come as a surprise I suppose. Everything else in the world is washed with warm water. This is obviously messy, I had scope and stock removed for this whole process.

JB Bore Paste - I needed it in this application to get that hard carbon ring out in my opinion. The wipe out may have gotten it over time but it would have taken a loooong time.

The result of all this effort is a clean (er) bore. I have yet to shoot it and see how it groups, maybe I destroyed it and this was a complete waste if time. I can't get to the range for a couple weeks so I will have to leave you all in suspense until then. I appreciate all the comments and recommendations so far. I've probably offended most of you but curiosity has got the better of me in this case and I need to see it through and see if/how performance is impacted.

Stay tuned.

For reference, Here is the as found bore.

And here is the as left bore after cleaning.

Here was my process.

The comment about getting the barrel HOT really intrigued me so using a funnel I poured a full kettle of boiling water down the barrel and got it very hot, too hot to touch. then a patch of hoppes (I don't recommend hoppes but it is the solvent I have on hand), then went at it with a bronze brush. I really think the heat helped here, there was so much crap coming out the brush was frothy. Then patched all that crap out with hoppes. Then a shot of wipe out down the barrel and left it for approx 12 hours.

The next morning I patched out the wipe out and got very blue patches. Another shot of wipe out and another 12 hours.

I did 4 rounds of Wipe out, checking progress with the scope every time. Copper was certainly being removed.

After the 4th round I went in with a bronze brush again to hit the carbon, patching out again with hoppes.

Then another 2 rounds of wipe out.

By this time the JB Bore Paste and Kroil had arrived. I followed the instructions and did 10 full barrel passes with a patch wrapped bronze brush. Then flushed out with hoppes. As you might expect this really got the remaining copper to move and the throat was getting shiny too. I did 10 more full passes with the JB and called the barrel good.

After that I just went after the carbon ring with JB and patches wrapped around an over sized brush.

Conclusions:

Wipe Out is fantastic. I'm sure the other copper solvents I tried were working but Wipe Out is so easy and safe. I'll be using this exclusively from now on.

Hoppe's 9 - I basically used hoppes here as a flushing agent and tried to use it up. Not going to be buying more.

Heated Barrel - Seems to help, shouldn't come as a surprise I suppose. Everything else in the world is washed with warm water. This is obviously messy, I had scope and stock removed for this whole process.

JB Bore Paste - I needed it in this application to get that hard carbon ring out in my opinion. The wipe out may have gotten it over time but it would have taken a loooong time.

The result of all this effort is a clean (er) bore. I have yet to shoot it and see how it groups, maybe I destroyed it and this was a complete waste if time. I can't get to the range for a couple weeks so I will have to leave you all in suspense until then. I appreciate all the comments and recommendations so far. I've probably offended most of you but curiosity has got the better of me in this case and I need to see it through and see if/how performance is impacted.

Stay tuned.

- Location

- Western Manitoba

If you are going to mess about heavy duty cleaning - especially if your barrel does not have front sight - or has 1/2" or so ahead of front sight - consider to find length of automotive heater hose that snuggly slides over that - I think I used 5/8" diameter - maybe 2" long - I use a hose clamp to tighten that up to be more or less "fluid proof" against the barrel - then used a wine bottle "plug" - apparently made for those that feel the need to store partial bottle of opened wine - as if that ever would happen around here!!! - so the "plugs" had never been used - another hose clamp on it, and I had an "cap" for end of barrel, that did not drip. I would set barrelled receiver vertical in soft jaw vice - muzzle down - fill barrel with "juice" - right to rear end of the chamber - and leave soak for over night, or several days - let that "juice" work away at whatever grunge in there - versus a "bung" which would prevent juice from getting at last part of rifling and grooves before the muzzle. I have done so with acetone, evaporust, paint thinner, ATF, brake cleaner, etc. - one "dripped" after a time, so I now set a metal can on floor under the muzzle to catch any drips - most stuff does not develop drip, though, if it was not dripping initially.

That's exactly what I envisioned as well. I was going to get some hose and a cheap valve but couldn't be bothered running out to the hardware store. I used a foam ear plug to bung the bore but without a way to bleed the air out you're right, you end up with an air pocket at the end. I know for next time though, that's a great idea.If you are going to mess about heavy duty cleaning - especially if your barrel does not have front sight - or has 1/2" or so ahead of front sight - consider to find length of automotive heater hose that snuggly slides over that - I think I used 5/8" diameter - maybe 2" long - I use a hose clamp to tighten that up to be more or less "fluid proof" against the barrel - then used a wine bottle "plug" - apparently made for those that feel the need to store partial bottle of opened wine - as if that ever would happen around here!!! - so the "plugs" had never been used - another hose clamp on it, and I had an "cap" for end of barrel, that did not drip. I would set barrelled receiver vertical in soft jaw vice - muzzle down - fill barrel with "juice" - right to rear end of the chamber - and leave soak for over night, or several days - let that "juice" work away at whatever grunge in there - versus a "bung" which would prevent juice from getting at last part of rifling and grooves before the muzzle. I have done so with acetone, evaporust, paint thinner, ATF, brake cleaner, etc. - one "dripped" after a time, so I now set a metal can on floor under the muzzle to catch any drips - most stuff does not develop drip, though, if it was not dripping initially.

- Location

- Western Manitoba

I do not think you will end up with an air pocket or bubble down there - any air will likely just float up through the fluid as you pour it in there - at least with the muzzle pointed down - but, so far as I can imagine, any thing inserted as a "bung" has to be snug to the rifling and grooves right at the bung - meaning the juice will not soak there - will be no contact, between the barrel and the "juice", right there, if a "bung" is used - and that may not often matter - but it might, if there is crap right there, at the muzzle.