Hi all,

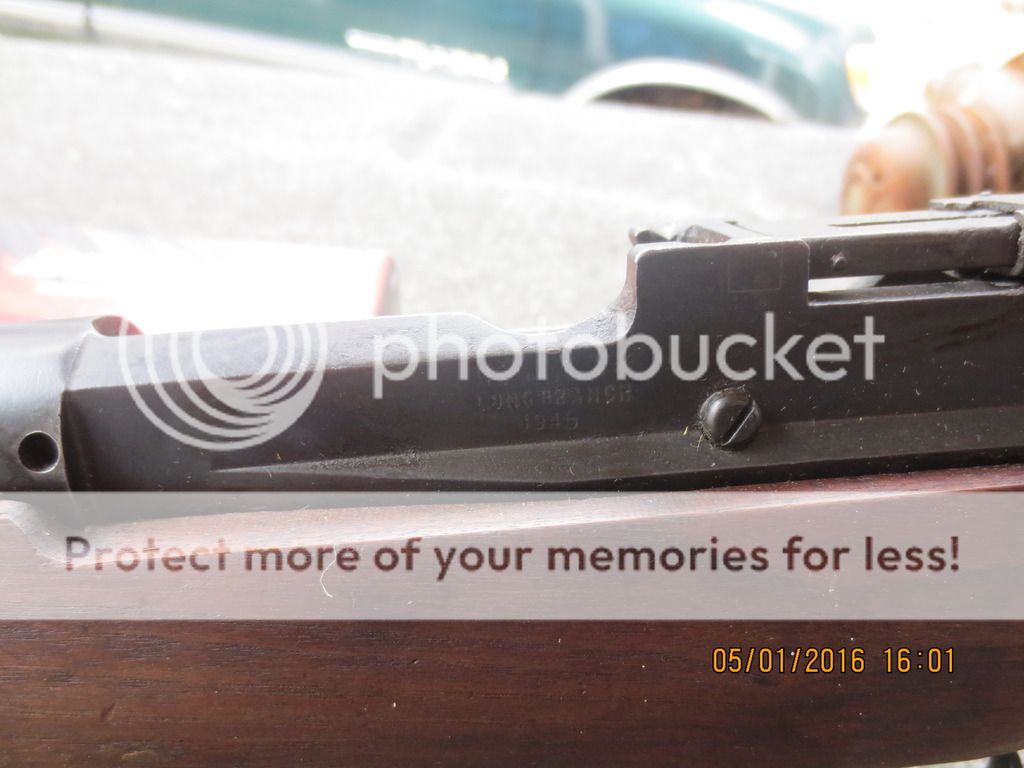

I recently picked up a Long Branch 1945 made rifle, and it is turning into a bit of a project. Would be interested to hear any info you folks might share about this one, as I am not a super knowledgeable guy on their markings, etc.

First of all, the stock is super clean, and very nice walnut. L marked butt, which is good for a big knuckle dragger like me. Top pieces do not look like they match. Wondering if a stock this nice is a replacement or maybe NOS? Finish is in super shape and there were actually traces of very old cosmoline outside and inside the action. Someone had cleaned it and fired it, but not very thoroughly and the bolt was a little gummy to work. I removed what remained.

Bore and rifling are super crisp and new looking.

Bolt body and mag match the rifles serial number. Cocking piece, safety do not seem to.

Strangely the front sight is the shortest one they make (-.3) marked. And the rifle seems to shoot very high at 100 yards. I say seems to because I only fired two factory Remington rounds. The second one produced a lot of smoke, and it turns out it had a pierced primer. I packed the rifle up and went home.

Guessing my first move here should be picking up a headspace gauge before messing with anything else? Bolt has a No 2 bolt head that looks visually in great shape, and is .634 in length according to my caliper. I have a hard time seeing a rifle this nice having excess headspace.

Anyway, here are some pics. Thanks in advance for whatever intel you fellows can provide!

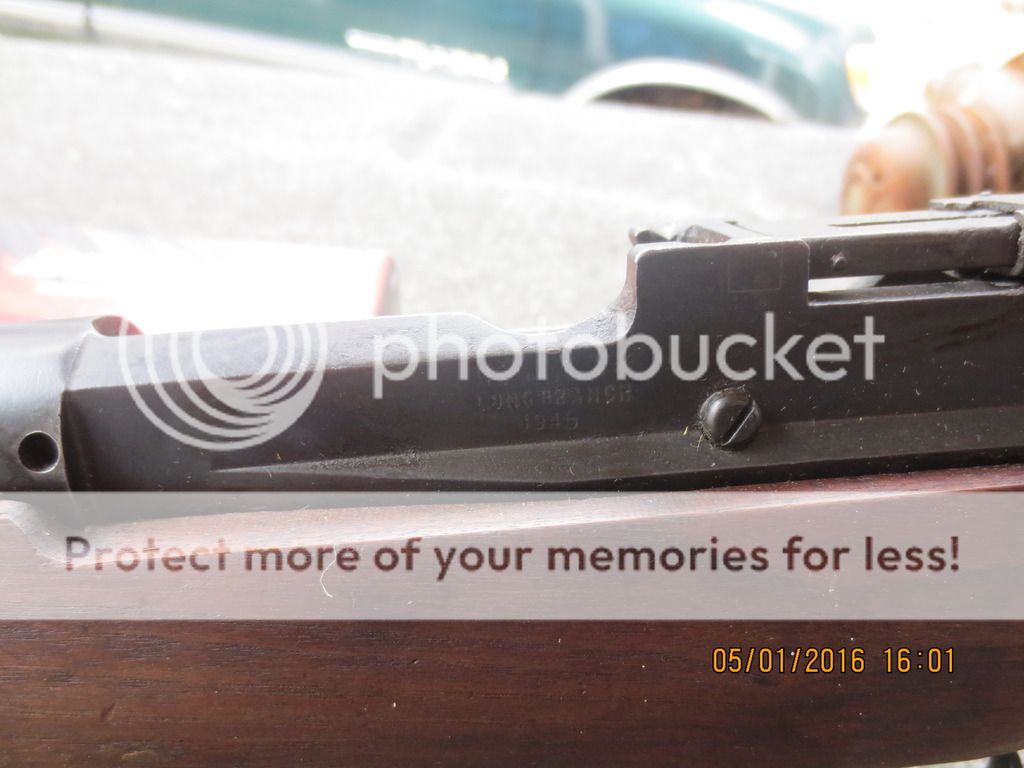

I recently picked up a Long Branch 1945 made rifle, and it is turning into a bit of a project. Would be interested to hear any info you folks might share about this one, as I am not a super knowledgeable guy on their markings, etc.

First of all, the stock is super clean, and very nice walnut. L marked butt, which is good for a big knuckle dragger like me. Top pieces do not look like they match. Wondering if a stock this nice is a replacement or maybe NOS? Finish is in super shape and there were actually traces of very old cosmoline outside and inside the action. Someone had cleaned it and fired it, but not very thoroughly and the bolt was a little gummy to work. I removed what remained.

Bore and rifling are super crisp and new looking.

Bolt body and mag match the rifles serial number. Cocking piece, safety do not seem to.

Strangely the front sight is the shortest one they make (-.3) marked. And the rifle seems to shoot very high at 100 yards. I say seems to because I only fired two factory Remington rounds. The second one produced a lot of smoke, and it turns out it had a pierced primer. I packed the rifle up and went home.

Guessing my first move here should be picking up a headspace gauge before messing with anything else? Bolt has a No 2 bolt head that looks visually in great shape, and is .634 in length according to my caliper. I have a hard time seeing a rifle this nice having excess headspace.

Anyway, here are some pics. Thanks in advance for whatever intel you fellows can provide!