You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My first reload

- Thread starter MissNoone

- Start date

I do have a Bullet Comparator just not a headspace.the method of finding oal with the glued-in bullet is fine also, as long as the measurement used is to the ogive and not the tip

fancy Hornady tool works but there are other methods with tool on the bench also

Well, I did not force/jam anything. The "DUMMY ROUND" I made was placed inside the action, then I slowly moved it forward in with my index finger till it stopped, then closed the bolt with little to no issue when locked.If you took a fully prepped case and stuck a bullet into it and forced it closed with the bolt I would bet you are jammed well beyond the start of the lands. For under 20 bucks you can get a Hornady oal gauge.

Not an idiot, just careless. We don't know how much we don't know when we start something new. Mistakes and bad assumptions are ok if you're building a bird house, but not if you're reloading....I thought I could just swap out powders. But again, I was just being an idiot.

You should get a loading manual and study the first chapters where they explain the basic how and whys of reloading. It's boring but worth the effort.

Even if nothing else good comes from this thread, learning that different powders aren't interchangeable is a major piece of knowledge, as is learning to be cautious.

mactroneng

CGN Ultra frequent flyer

- Location

- SW Ontario

That COAL determination is definitely wonky... both the fact that your measurement is almost certainly jammed into the lands at least a bit, and because COAL is not indicative of ogive as others have mentioned.

I came up with a method myself, which is based on this method but doesn't involve removing the barrel. I get very repeatable measurements from it and haven't had any issues:

Prelim: Buy a tool to measure ogive if you don't have one (ensure it is steel not aluminium or anything softer). I already had one because using as a baseline for seating depth is infuriatingly all over the place.

1) Get 1 piece of brass sized.

2) Remove your bolt and insert the empty brass into your chamber, seating it with a light tap from your finger (not a tool of any kind). Lower a dowel in behind it and mark it somewhere where you can repeatedly reference to the gun (ex. back end of the receiver where you took the bolt out).

3) Insert a bullet in the brass to a length you are reasonably certain is too long (or if using a mag-fed gun, the max that will fit in the mag as you're not going beyond that even if you don't run up against the lands... I highly recommend this for mag-fed guns as the first time I did this for a gun I wasted a lot of time getting a measurement then realized completed rounds were too long for the mag so it didn't matter. But still useful to continue if you ever change bullets).

4) Gently lower the case + bullet into the chamber until it stops and apply the light tap (finger only, no tools!) as in Step 2. Gently lower your dowel on top of it. This will give you can idea how much further in to seat the bullet.

5) Seat the bullet in further according to what you think makes sense.

6) Repeat Steps 4 and 5 until your mark on the dowel is at your reference point on the gun you used in Step 2. Record this ogive measurement.

7) Seat your bullet 20 thou deeper and re-insert, it should be able to fall out freely when you overturn the gun.

8) Re-insert the bullet+case but press the case in there this time. Unless your chamber is dirty the case+bullet should still fall out when you overturn the gun, or at worst give it gentle shake.

The key to the above method is not to force the case into the chamber until you've completed up to and including Step 7. I've been wary of any methods that involve trying to close the bolt to see if the length is good, too easy to jam it in the lands.

I came up with a method myself, which is based on this method but doesn't involve removing the barrel. I get very repeatable measurements from it and haven't had any issues:

Prelim: Buy a tool to measure ogive if you don't have one (ensure it is steel not aluminium or anything softer). I already had one because using as a baseline for seating depth is infuriatingly all over the place.

1) Get 1 piece of brass sized.

2) Remove your bolt and insert the empty brass into your chamber, seating it with a light tap from your finger (not a tool of any kind). Lower a dowel in behind it and mark it somewhere where you can repeatedly reference to the gun (ex. back end of the receiver where you took the bolt out).

3) Insert a bullet in the brass to a length you are reasonably certain is too long (or if using a mag-fed gun, the max that will fit in the mag as you're not going beyond that even if you don't run up against the lands... I highly recommend this for mag-fed guns as the first time I did this for a gun I wasted a lot of time getting a measurement then realized completed rounds were too long for the mag so it didn't matter. But still useful to continue if you ever change bullets).

4) Gently lower the case + bullet into the chamber until it stops and apply the light tap (finger only, no tools!) as in Step 2. Gently lower your dowel on top of it. This will give you can idea how much further in to seat the bullet.

5) Seat the bullet in further according to what you think makes sense.

6) Repeat Steps 4 and 5 until your mark on the dowel is at your reference point on the gun you used in Step 2. Record this ogive measurement.

7) Seat your bullet 20 thou deeper and re-insert, it should be able to fall out freely when you overturn the gun.

8) Re-insert the bullet+case but press the case in there this time. Unless your chamber is dirty the case+bullet should still fall out when you overturn the gun, or at worst give it gentle shake.

The key to the above method is not to force the case into the chamber until you've completed up to and including Step 7. I've been wary of any methods that involve trying to close the bolt to see if the length is good, too easy to jam it in the lands.

Last edited:

it is quite frustrating when I read here and you guys disagree with what the Internet says I watched so many Youtubers, read so many articles that said that I should have my bullet as Close as possible to the lands and even touching it would not be a bad thing. I have ordered an overall length gauge I'll have it here next week sometime and I will compare my dummy round to another dummy round and see the difference.Loading them into the lands is a no no regardless (you mention 0.010 to 0.020, I would prefer 0.020 but that's just me).

- Location

- Nova Scotia

Well you punished yourself enough. Chalk this to learning. Glad you posted it before you went to the range. But reloading is one of those activities you need its full attention. Also stuff like crimp can cause issues. Too much and it can build up pressure more. Still have alot to learn.It's because I was being an idiot, reading the wrong load data, and I wasn't using my brain. And for some reason, I thought I could just swap out powders. But again, I was just being an idiot.

- Location

- Nova Scotia

Cannot always trust what you read on the internet. Like you cannot trust people behind gun counters to being correct either. I have loads, that OAL dictates pressure and no pressure signs and all it takes is a few thou difference. Some powders peak performance is at max.it is quite frustrating when I read here and you guys disagree with what the Internet says I watched so many Youtubers, read so many articles that said that I should have my bullet as Close as possible to the lands and even touching it would not be a bad thing. I have ordered an overall length gauge I'll have it here next week sometime and I will compare my dummy round to another dummy round and see the difference.

I remember reading a post here on this thread as someone saying that I didn't mention my resizing data. so here it is

I did resize using the following die set.

I used the Hornady Match Grade .300 Winchester Magnum die set and resized the cases with a .332 collet insert. I arrived at this choice based on the sizing instructions from the Hornady website; I calculated the difference and determined this was the appropriate insert.

Once I finished that, I used the Belted Magnum Collet Resizing Die to resize the bottom of the casing just above the belt. This step was necessary because none of my casings would fit into the chamber before resizing. After using this die, I was able to fill my magazine and run all five rounds without any issues. I could even load the empty prepped casing and, with my fingers, remove the magazine, push the rounds back into the chamber, and then gently tip the rifle to let the casing fall out.

I did resize using the following die set.

I used the Hornady Match Grade .300 Winchester Magnum die set and resized the cases with a .332 collet insert. I arrived at this choice based on the sizing instructions from the Hornady website; I calculated the difference and determined this was the appropriate insert.

Once I finished that, I used the Belted Magnum Collet Resizing Die to resize the bottom of the casing just above the belt. This step was necessary because none of my casings would fit into the chamber before resizing. After using this die, I was able to fill my magazine and run all five rounds without any issues. I could even load the empty prepped casing and, with my fingers, remove the magazine, push the rounds back into the chamber, and then gently tip the rifle to let the casing fall out.

First thing Miss, your not an idiot! You came seeking information before you pulled the trigger, and we all thank you for that!!

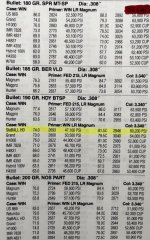

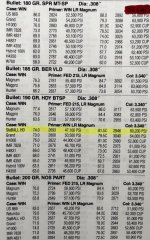

This sheet was taken from the 2024 Hodgdon Reloading annual manual. I think I would have chosen a different powder to start off with,something like 4831 or one of the 4350's with more data behind them.

Max ovl for the Speer 180gr is listed at 3.285 so that is where I would start -for now.

It looks like the 300 Win mag is right on the bottom of usability of HD as 190gr is the starting weight for projectiles while other calibers like the 300 prc have data as low as 150gr and 30 Nosler at 130gr.

Data for HD with a 190gr soft point of 'similar' construction to the Speer shows starting loads of 74.0 to a max of 81.5gr. I think I'd be comfortable starting at 74.0 with your 10gr lighter bullet and work up from there.

This sheet was taken from the 2024 Hodgdon Reloading annual manual. I think I would have chosen a different powder to start off with,something like 4831 or one of the 4350's with more data behind them.

Max ovl for the Speer 180gr is listed at 3.285 so that is where I would start -for now.

It looks like the 300 Win mag is right on the bottom of usability of HD as 190gr is the starting weight for projectiles while other calibers like the 300 prc have data as low as 150gr and 30 Nosler at 130gr.

Data for HD with a 190gr soft point of 'similar' construction to the Speer shows starting loads of 74.0 to a max of 81.5gr. I think I'd be comfortable starting at 74.0 with your 10gr lighter bullet and work up from there.

- Location

- Saskatoon Saskatchewan

Im glad you asked here before firing the reloads. You're not an idiot. Just need more information. You actually dont need a coal gauge. You can find your max coal by taking a piece of fired brass, dabbing a small amount of crazy glue inside the neck and gently chambering it in your rifle with the bullet you have chosen inserted in the case neck. Sometimes you have to but a bit of a dent right at the case mouth to hold the bullet firmly.

Let the dummy round sit in the chamber until the glue has time to dry and gently extract it. I like to but a bit of case lube on the bullet so it doesn't easily stick in the leade.

You now would have a dummy round to measure the length to your lands for THAT bullet. The olive measurement will change from bullet to bullet. This will be your max coal to lands and you should seat your bullets at a length less than that.

Let the dummy round sit in the chamber until the glue has time to dry and gently extract it. I like to but a bit of case lube on the bullet so it doesn't easily stick in the leade.

You now would have a dummy round to measure the length to your lands for THAT bullet. The olive measurement will change from bullet to bullet. This will be your max coal to lands and you should seat your bullets at a length less than that.

- Location

- WMU248 near Edmonton

I load 300WM along with about 30 other cases and have been doing so for over 2 decades.

I see you sorted out your powder and have some load data to work with (I use IMR4831 myself with a 200grn Nosler Acubond) but choosing powder is a bit of voodoo and black magic. I try to use a slower powder that results in a maximum fill rate for the case without getting into compressed loads.

measuring for your COL is something else, I use a similar method, dummy round chambered and that gives you your maximum chamber to the lands, then back it off 0.030" my reloads (Savage 10) are also over published book max COL, and my limiting factor is what fits in the magazine. So over max COL is not an issue but you need to have a bit of a lead (0.030" is recommended) to allow the bullet to 'jump'. If the bullet is placed against the lands there is a bit more resistance and this delays the bullet slightly and in doing so you have a slightly higher chamber pressure. This will effect your maximum loads.

With my load I have worked up a load that is slightly over the book maximum and launches a 200grn bullet at 2960FPS and is a consistent 1.5" group, but that took a while to work up to, and is only good in my specific rifle.

also your going above and beyond with your case prep

I tumble clean, remove primers, neck size, check length (trim if required) tumble clean again, new primers, powder, seat bullet, crimp. The crimp (lee factory crimp die) is an optional step but I do it for hunting ammo that can be treated roughly and anything with a heavy recoil and 30-30 that uses a tube mag. There are lots of opinions on crimping

I see you sorted out your powder and have some load data to work with (I use IMR4831 myself with a 200grn Nosler Acubond) but choosing powder is a bit of voodoo and black magic. I try to use a slower powder that results in a maximum fill rate for the case without getting into compressed loads.

measuring for your COL is something else, I use a similar method, dummy round chambered and that gives you your maximum chamber to the lands, then back it off 0.030" my reloads (Savage 10) are also over published book max COL, and my limiting factor is what fits in the magazine. So over max COL is not an issue but you need to have a bit of a lead (0.030" is recommended) to allow the bullet to 'jump'. If the bullet is placed against the lands there is a bit more resistance and this delays the bullet slightly and in doing so you have a slightly higher chamber pressure. This will effect your maximum loads.

With my load I have worked up a load that is slightly over the book maximum and launches a 200grn bullet at 2960FPS and is a consistent 1.5" group, but that took a while to work up to, and is only good in my specific rifle.

also your going above and beyond with your case prep

I tumble clean, remove primers, neck size, check length (trim if required) tumble clean again, new primers, powder, seat bullet, crimp. The crimp (lee factory crimp die) is an optional step but I do it for hunting ammo that can be treated roughly and anything with a heavy recoil and 30-30 that uses a tube mag. There are lots of opinions on crimping

Last edited:

Actually, just recently watched a YouTuber talk about not to crimp unless your bullets have that crimp line forgot what it’s called. Or is that not entirely correct?The crimp

OK, so I decided I’m going to load my horny 168BTHP by the data that I have. Now, do I need to subtract the 5% from the lowest amount?

The lowest is 72grn at 2700fps, 74.8grn 2800fps, 77.5grn 2900fps, 80.3grn 3000fps 83grn 3100fps and the max is 85.8grn 3200fps.

If I don’t need to subtract the 5% should I just then load five of each group?

The lowest is 72grn at 2700fps, 74.8grn 2800fps, 77.5grn 2900fps, 80.3grn 3000fps 83grn 3100fps and the max is 85.8grn 3200fps.

Last edited:

What are you gonna do if the ammo you load to the lands is LONGER then your magazine lenght - Just shoot Single Shotit is quite frustrating when I read here and you guys disagree with what the Internet says I watched so many Youtubers, read so many articles that said that I should have my bullet as Close as possible to the lands and even touching it would not be a bad thing. I have ordered an overall length gauge I'll have it here next week sometime and I will compare my dummy round to another dummy round and see the difference.

I could, but I do measure each cartridge as I complete them. for now as been suggested I’m going to follow exactly what the date says, and then work from there.What are you gonna do if the ammo you load to the lands is LONGER then your magazine lenght - Just shoot Single Shot

Not at all Correct - It called a Cannelure or Crimping groove - Lots of Bullets do not have one . Some bullet manufactures use this groove as a guide to bullet seating deapth !Actually, just recently watched a YouTuber talk about not to crimp unless your bullets have that crimp line forgot what it’s called. Or is that not entirely correct?

So should I readjust my seat guy so that I apply a crimp? Right now I backed it off about a half a turn.Not at all Correct - It called a Cannelure or Crimping groove - Lots of Bullets do not have one . Some bullet manufactures use this groove as a guide to bullet seating deapth !

Loading into the lands is a commonly accepted practice.it is quite frustrating when I read here and you guys disagree with what the Internet says I watched so many Youtubers, read so many articles that said that I should have my bullet as Close as possible to the lands and even touching it would not be a bad thing. I have ordered an overall length gauge I'll have it here next week sometime and I will compare my dummy round to another dummy round and see the difference.

IMO the position of the bullet can be:

Jumping to the lands

At the lands

Touching the lands

Soft jam in the lands

Hard jam in the lands

The lands dont start at a 90° angle to the bore. They start at some angle like 15 or 30° so it is a gradual transition from freebore diameter(bullet diameter generally) to the smaller diameter rifled portion of the bore.

Therefore... theres a very fine line between being at the lands -.001", in the lands .001", soft jammed in the lands .010", or hard jammed into the lands .040" which is basically cramming the bullet tight into the angle.

Unless you know the cartridge and components and reamer(think repeatable and known target rifle and knowing a particular bullet likes .010 soft jam and the cartridge, reamer, and components will NOT be excessive pressure) it is best to be jumping to the lands some amount(longer free bores are machined into heavy cartridges to reduce pressure and run any off the shelf factory ammo rain snow or shine friday afternoon vs monday ammo). Establish your velocity and pressure signs before attempting to be at in or jammed into the lands.

There are more consequences to being in the lands than there are benefits if you dont have an idea of what the combination will do.

It is very easy to be .001" in the lands or .040" into the lands due to the gradual start of the rifling depending on the method used to find the lands. To confidently say exactly where the lands start is an accomplishment on its own.

Id wager a small bet that load development in a 300 win mag should start well off the lands.

Ultimately, the lands is a fine tuning aspect of hand loading and the start of the rifling is continually eroding and moving further away everytime you pull the trigger. It only gets measured once. You could simply hard jam a bullet, remove .050" off that base to ogive measurement, and shoot. It's not critical at this point. If you decide to try say 80gr of powder hard jammed in the lands, you should already know that the rifle does not have pressure signs at a jump, at, touching, and soft jammed in the lands.

Most manuals say DO NOT go below the lowest charge listed.OK, so I decided I’m going to load my horny 168BTHP by the data that I have. Now, do I need to subtract the 5% from the lowest amount?

The lowest is 72grn at 2700fps, 74.8grn 2800fps, 77.5grn 2900fps, 80.3grn 3000fps 83grn 3100fps and the max is 85.8grn 3100fps.

If I don’t need to subtract the 5% should I just then load five of each group?

Unless I missed it, I'm curious as to what firearm your using and if you've already sighted it in with factory ammo? If so loading the above charges in 3 0r 5 rounds are ok, just that 30 rounds can make for a long day-even 18 can be punishing!