Wondering if anyone has encountered this?

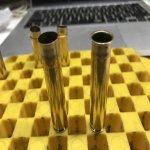

I make brass for my 9.3X57 rifle from 8X57 Mauser brass.

I initially bought a batch of Metalwerken brass and had no issues, other than a slightly thick neck near the shoulder.

I then tried WW Super (Winchester) brass and had no neck issue. The sizing die setting remained the same. However, the spent primers were protruding after the initial firing, and the case was shiny just above the base, which are indications that the cases are not headspacing properly. After the second load, the primers were OK but flat. After the third load, I experienced case separation above the case head.

I have not had this happen with any of the Metalwerken cases, only with the Winchester.

Is this true of all Winchester 8X57 brass, or did I just buy a batch that is sized slightly short?

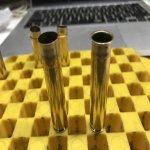

I make brass for my 9.3X57 rifle from 8X57 Mauser brass.

I initially bought a batch of Metalwerken brass and had no issues, other than a slightly thick neck near the shoulder.

I then tried WW Super (Winchester) brass and had no neck issue. The sizing die setting remained the same. However, the spent primers were protruding after the initial firing, and the case was shiny just above the base, which are indications that the cases are not headspacing properly. After the second load, the primers were OK but flat. After the third load, I experienced case separation above the case head.

I have not had this happen with any of the Metalwerken cases, only with the Winchester.

Is this true of all Winchester 8X57 brass, or did I just buy a batch that is sized slightly short?