You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Please remove

- Thread starter HUNTERROD

- Start date

The thimble is missing, i was told guns in this batch were unassembled when stored. The barrel was ordered as 24" , gun was used as a hunting carbine.

The tang area, ill add pics...yesterday it was next to impossible to load pictures

...i wish they'd find an easier way. Ive been wanting an entry thimble but

...i wish they'd find an easier way. Ive been wanting an entry thimble but

Not sure what would fit or where to look . to bad in canada we have nobody importing kits/parts etc...

Really think it would be a big boost to black powder.

The tang area, ill add pics...yesterday it was next to impossible to load pictures

...i wish they'd find an easier way. Ive been wanting an entry thimble but

...i wish they'd find an easier way. Ive been wanting an entry thimble butNot sure what would fit or where to look . to bad in canada we have nobody importing kits/parts etc...

Really think it would be a big boost to black powder.

Attachments

Last edited:

Attachments

Last edited:

Should be able to get an entry pipe that could be adapted - the rifle was probably assembled using commercial parts. If not, one would have to be made.

As a Hawken, it looks really odd with the short barrel. May make it handy for hunting, but spoils the classic Hawken appearance.

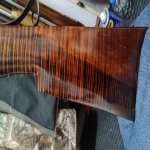

Beautiful piece of maple!

What is the story with the trade gun in the top picture?

As a Hawken, it looks really odd with the short barrel. May make it handy for hunting, but spoils the classic Hawken appearance.

Beautiful piece of maple!

What is the story with the trade gun in the top picture?

Nice rifle, my guess is the barrel could be a GRRW. The entry thimble is easily replaced. TOW or other suppliers will have the part. I would seriously consider fixing the nipple / hammer alinement. If you wish to sell it I think you would do much better with a longer barrel. Always good to see nice muzzleloaders.

I dont have any way to address the alignment

, no shops near by, dont have the luxury of having oskar near by or steve around anymore i dont really wanna sell, unless i found a flintlock 45 long rifle

Or a flint 45 cal hawken/plains type gun. I still have the 50cal thompson steve and i built, have a lyman 50cal hawken, a 58 cal zoli Mississippi rifle and a David Dolliver trade gun built in 1998. Signed. Id like a smaller bore gun

, no shops near by, dont have the luxury of having oskar near by or steve around anymore i dont really wanna sell, unless i found a flintlock 45 long rifle

Or a flint 45 cal hawken/plains type gun. I still have the 50cal thompson steve and i built, have a lyman 50cal hawken, a 58 cal zoli Mississippi rifle and a David Dolliver trade gun built in 1998. Signed. Id like a smaller bore gun

I dont have any way to address the alignment

, no shops near by, dont have the luxury of having oskar near by or steve around anymore i dont really wanna sell, unless i found a flintlock 45 long rifle

Or a flint 45 cal hawken/plains type gun. I still have the 50cal thompson steve and i built, have a lyman 50cal hawken, a 58 cal zoli Mississippi rifle and a David Dolliver trade gun built in 1998. Signed. Id like a smaller bore gun

I would have to agree with Wayne on the nipple, it does look like it may not be threaded all the way in, if not that would help a little with the alignment. You would still need a bit of a bend on the hammer. (you should be able to do that pretty easy with a propane torch. (MAPP or Oxy/Acetylene would be easier)

The other thing you can do is use a centre cutting end mill to cut the inside face of the hammer to the right angle.

Double check the twist on that barrel? If it was a custom order - being that short, it might have a faster twist for bullets. (as opposed to round ball - Rice will do a custom twist)

Seen all those parts before -- it's either Petatonica River or Track kit parts ... the entry pipe will be the same on both. just grab the part and cut/file to the inlet you have. Probably a much easier job than inletting a new thimble

Nice wood!

As to value? Well, getting the parts up here is going to be $1100ish CDN if you get hit with duty, add another couple hundred. Then either paying someone or your time to build one.

I would love to tell you $2,000.00 - $2,500.00, but I can't.

I would hope break even on your trade is at least $800.00, I don't think I would take less than $1,000.00. so $1,000.00 - $1,500.00 on the high end. Lean more towards the high end if that barrel has a fast twist & hope you find the right guy on the right day.

I appreciate that sean, i wish oskar was still a 15 min drive. Away, unfortunately hes moved, also hes a very dear friend, and i know wayne as well. Oskar and i worked on plenty of projects together, he case colored a few for me also.the rifling in this barrel is

Very heavy...deep.. It points extremely fast, the gent was using it as a bush gun..so compact eas key and keeping weight down id guess. I collect sxs shotguns

With twist/damascus barrels mainly.

Very heavy...deep.. It points extremely fast, the gent was using it as a bush gun..so compact eas key and keeping weight down id guess. I collect sxs shotguns

With twist/damascus barrels mainly.

It points extremely fast, the gent was using it as a bush gun..so compact eas key and keeping weight down id guess.

I'll bet!! that's a full 12-14" off a traditional length barrel ... anything under .54 36-38" will be pretty beastly to lug around.

vagrantviking

CGN Ultra frequent flyer

- Location

- Southern Alberta

That's beautiful wood and quality parts. It would probably be getting close to $1500 in parts reproduce it but, as mentioned, the market here would make it difficult to sell for that. Might be a little easier with 30 inch or longer barrel and a round ball twist.

Shame about the hammer alignment but its fixable. Sounds like you know some of the right people who can lend advice and help get it sorted out. Going to be fun on the range!

Shame about the hammer alignment but its fixable. Sounds like you know some of the right people who can lend advice and help get it sorted out. Going to be fun on the range!

The hammer is not offset barely at all it strikes nipple gd..the nipple is fully seated , its an L&R lock

What Wayne & I are suggesting is that the hammer is hitting the rim of the nipple (it is, we can see it

1. You could have ignition issues - a square hit by the hammer seals up the nipple, hitting the rim like that allows some gasses to blow out the front/sides so "possible ignition reliability issues"

2. The hammer will eventually bend and mushroom the nipple, making the angle worse, and when it starts to deform you won't be able to get a cap on there. A properly seated cap actually helps keep the nipple from mushrooming. (as will a titanium nipple

I don't remember having to offset or bend the hammer on any of the Hawkens I've done - it is possible the hole for the nipple was drilled at a bad angle too....

put a couple layers of masking tape over the nipple and drop the hammer on it - the mangled bits of tape will tell you exactly how the hammer contacts the nipple - in reality it looks like the nipple is making contact right in the corner of the cup ... i.e. it is hitting both front and rear lips of the nipple at the same time. not optimal, but it appears to work. if that's the case leave it unless it starts mangling nipples. (i.e. carry a couple extra nipples)