Yes, if you want to try to match the tensile strength of your lead alloy to the chamber pressure you think you'll be getting with your load. Doing that, along with the fit of your cast bullets in the ball seat portion of your chamber goes a long way towards developing high quality cast bullet loads for rifles.Are there advantages to quenching cast lead bullets?

Ken Mollohan and Tom Gray explored this for years as Cast Bullet Association benchrest competitors and hunting with cast bullets, and I think Ken wrote a piece on it for Lyman for one of the editions of their cast bullet manual.

For me, the best way to heat treat (as well as powder coat bullets) is to put the bullets base down in one of those silicon mini icecube trays, and from there into the oven, and after that you can drop the tray with all the bullets into a water bath in a five gallon pail or whatever you wish. These will fit up to at least .35 caliber bullets, which is the largest I cast for.

You get consistent heating and cooling results, versus doing it one bullet at a time with some other method.

From my notes and pieces of information I saved while Ken was mentoring me through learning to develop high quality cast rifle loads:

HEAT TREATING WHEELWEIGHTS

Heat treating wheel weight alloy is both controllable and predictable i.e.: it is possible to

heat treat wheel weight bullets and predict the final hardness to be achieved.

Hardness does not begin to increase until the quench temp (after a ½ hr heat soak) reaches a

minimum of 420deg. F. as measured with a digital thermometer shaded from direct radiant heat.

Temperature vs. Resulting Hardness

410 - 12 BHN

420 - 15 BHN

430 - 17 BHN

440 - 23 BHN

450 - 29 BHN

Conclusions:

Exceeding 450 did not cause any significant increase in hardness. 460 deg is very

close (meaning too close) to the plastic deformation stage of bullet alloy.

Common BHN measurements:

Pure lead: 5 BHN

40-1 Lead-tin: 8.5 BHN

30-1 Lead-tin: 9 BHN

20-1 Lead-tin: 10 BHN

16-1 Lead-tin: 11 BHN

10-1 Lead-tin: 11.5 BHN

Wheel weights: 8-13 BHN (alloy composition varies)

Lead/linotype: 15 BHN (half and half)

Linotype: 22 BHN

Lyman No. 2 15 BHN

Heat treated W-W 25-35 BHN (varies with heat treatment and age)

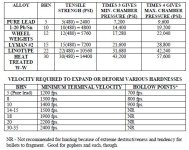

OPTIMAL HARDNESS FOR CHAMBER PRESSURE OF LOAD

Tensile strength of lead/lead alloys = BHN x 480 (480 is metallurgy factor for lead)

Best bullet performance is usually when the reload’s chamber pressure is between 3 and

4 times the BHN of the bullet alloy.