Recently re-barreled a savage long action with a 30" JC Custom Barrel, 1" - .95" straight taper, and want to share my load development with you all, and hear your comments on my methods!

I had two suitable powders on hand H-1000, and H4831SC. Enough to load about 100 rounds each.

Using Berger 210 Grain VLD Bullets

COAL 3.579" (10 thou jump)

H4831SC

Starting load 66.5, working up in .3 grain increments to 69.8 grains (per the Berger Reloading Manual).

Started with new unfired PRVI brass, Body Sized, Neck Sized, Trimmed, and Chamfered, flash holes cleaned (this batch of brass had a number of brass with the flash hole partially obstructed).

Loaded 3 rounds of each powder weight

H1000

Starting load 71.5 grains, and working up in .3 grain increments to 74.8 grains (per the Berger Reloading Manual).

Used some fired brass (out of a different barrel), Body sized, Neck Sized, Trimmed, and Chamfered

Loaded 3 rounds of each powder weight

Range Day!

Jan 20/19, 10:40am, Clear Skies, -13C (w/o wind), Wind L-R ~20km/h (enough to blow targets and mitts of the shooting tables if they were not weighted down).

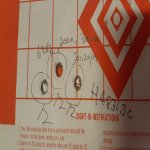

200m Target

Shooting from a Bench

Front Rest: Caldwell "The Rock", with stock stop to ensure consistent placement on the rest.

Rear Rest: Integrated Rear Adjustment Screw in my rifle stock

Notes:

Scope has been remounted, first time firing rifle since I replaced the barrel, and re-assembled the rifle.

All of the H1000 loads were difficult to close the bolt, at first I thought it was the bullet being jammed into the lands (I assumed I didn't get the jump correct), after trying a few rounds, looks like perhaps headspace was too tight for this older brass and was headspacing off of the shoulder, and not the belt.

H4831SC loads chambered fine, except for a couple of rounds (it was cold, and I chalked it up to as weather related).

No sticky bolt on ejection, only on chambering.

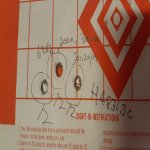

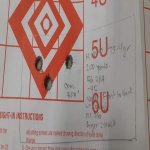

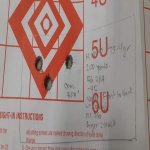

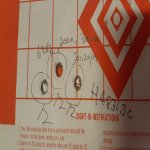

I would shoot 4 of the loads (12 rounds), at 4 targets (1 each), then walk down range, note each hit with a marker, and re-use the target. Typically I would use new targets each time, but this was quicker and less time with my hands out of my mitts, and the walking warmed me up.

Pictures!

I had two suitable powders on hand H-1000, and H4831SC. Enough to load about 100 rounds each.

Using Berger 210 Grain VLD Bullets

COAL 3.579" (10 thou jump)

H4831SC

Starting load 66.5, working up in .3 grain increments to 69.8 grains (per the Berger Reloading Manual).

Started with new unfired PRVI brass, Body Sized, Neck Sized, Trimmed, and Chamfered, flash holes cleaned (this batch of brass had a number of brass with the flash hole partially obstructed).

Loaded 3 rounds of each powder weight

H1000

Starting load 71.5 grains, and working up in .3 grain increments to 74.8 grains (per the Berger Reloading Manual).

Used some fired brass (out of a different barrel), Body sized, Neck Sized, Trimmed, and Chamfered

Loaded 3 rounds of each powder weight

Range Day!

Jan 20/19, 10:40am, Clear Skies, -13C (w/o wind), Wind L-R ~20km/h (enough to blow targets and mitts of the shooting tables if they were not weighted down).

200m Target

Shooting from a Bench

Front Rest: Caldwell "The Rock", with stock stop to ensure consistent placement on the rest.

Rear Rest: Integrated Rear Adjustment Screw in my rifle stock

Notes:

Scope has been remounted, first time firing rifle since I replaced the barrel, and re-assembled the rifle.

All of the H1000 loads were difficult to close the bolt, at first I thought it was the bullet being jammed into the lands (I assumed I didn't get the jump correct), after trying a few rounds, looks like perhaps headspace was too tight for this older brass and was headspacing off of the shoulder, and not the belt.

H4831SC loads chambered fine, except for a couple of rounds (it was cold, and I chalked it up to as weather related).

No sticky bolt on ejection, only on chambering.

I would shoot 4 of the loads (12 rounds), at 4 targets (1 each), then walk down range, note each hit with a marker, and re-use the target. Typically I would use new targets each time, but this was quicker and less time with my hands out of my mitts, and the walking warmed me up.

Pictures!

Attachments

Last edited: