You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rem 700 firing pin spring

- Thread starter bigHUN

- Start date

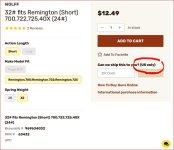

Wrong. That's just an option to check if you can ship to a specific state in the US. They will ship those springs to Canada. I tried checking out and it works.

If that was correct you couldn't buy anything from brownells.

If that was correct you couldn't buy anything from brownells.

Discussions on firing pin springs have come to the forefront recently. Shooters in the US are recommending to replace them with each barrel swap. We're a bit more limited for parts in the GWN, plus I believe that quality parts should not be changed out so soon. My opinion is that you should look at swapping out every third barrel in a competition rifle if you know you have a quality part like a Wolfe or Tubb. It's a consumable, just like your barrel.

Springs are an interesting variable ... 28# seems to be the main one used in the Rem 700 in competition, but there are other weights as well to consider. As always, test your spring replacement prior to using it in serious situations like hunting or competition. Ignition consistency in all temperatures to be encountered in use are important.

Springs are an interesting variable ... 28# seems to be the main one used in the Rem 700 in competition, but there are other weights as well to consider. As always, test your spring replacement prior to using it in serious situations like hunting or competition. Ignition consistency in all temperatures to be encountered in use are important.

Recently retired, a plenty of time on my plate. Also winter here, with about a meter snow in my backyard (just North of Toronto).Discussions on firing pin springs have come to the forefront recently.......As always, test your spring replacement prior to using it in serious situations like hunting or competition. Ignition consistency in all temperatures to be encountered in use are important.

My 3d printed tool is ready, waiting for delivery.

Also finishing the push force meter project.

No big problems only great solutionsJeez - talk about 'blah' for 'no real problem, "just tinkering" - 47 posts

Can we just have a conversation? Just anything. What else you would talk about? Always about a blue sock guy, efhim....

All we have questions and opinions and why not spend some leasure time together

Why is a sad face Buck1950?

honestly

if you don't like it you don't read it....and don't waste your time replying.

As the saying goes sometimes nothing said is better than mean or insulting comments. Its not hard to read a question and pass without answering.

Maybe this new year has caused me to become a grumpy older man; being older is the keyword.

I also think I post too much; winter may have something to do with that or not.

honestly

if you don't like it you don't read it....and don't waste your time replying.

As the saying goes sometimes nothing said is better than mean or insulting comments. Its not hard to read a question and pass without answering.

Maybe this new year has caused me to become a grumpy older man; being older is the keyword.

I also think I post too much; winter may have something to do with that or not.

Last edited:

I've purchased Gretan complete firing pin assemblies from Brownells before, liked everything except the shroud, aluminum and not quite the same color, just used the Remington shroud on them.

Couple benefits, firing pin body is polished up nice and smooth, cocking piece is milled and not MIM or whatever Remington makes them out of.

You will need a tool to disassemble the firing pin spring. Not sure I would trust that 3D plastic affair for this job lol.

Now I just take the OEM assemblies apart and polish the pin body myself, doesn't cost anything, the pins are rough and sharp as hell on the flutes, not sure it does anything except make me feel better lol.

Couple benefits, firing pin body is polished up nice and smooth, cocking piece is milled and not MIM or whatever Remington makes them out of.

You will need a tool to disassemble the firing pin spring. Not sure I would trust that 3D plastic affair for this job lol.

Now I just take the OEM assemblies apart and polish the pin body myself, doesn't cost anything, the pins are rough and sharp as hell on the flutes, not sure it does anything except make me feel better lol.

For years I am designing and 3d printing final and usable prototype parts on contract, also for my airgun and biking accessories and tools.... Not sure I would trust that 3D plastic affair for this job lol....

All I am using engineering resins (several Brands), and this one in picture above is for example hard-tough ABS like, machinable (mill, drill, tap) and not brittle.

I printed in this colour just because this was left in the machine from last time.

Another way to disassemble the striker assembly is to get/make a spacer and drop it into the bolt body. Then you start screwing the striker into the body and let the bolt take itself apart.

Shamelessly stole that from Guntech.

Shamelessly stole that from Guntech.

My street mailbox is buried deep after the snow plowers passed several times through the street, and today my postman lady ring at the door  and delivered me this package smiling... she knew she made my day

and delivered me this package smiling... she knew she made my day

The comparison visually shows a smaller cross section but more (reversed left hand) coils on new string, also just trying by hand the new assembly is considerably higher power. I need to pull out my press force meter from a box, I will definitely compare the two assemblies just for my own interest.

The comparison visually shows a smaller cross section but more (reversed left hand) coils on new string, also just trying by hand the new assembly is considerably higher power. I need to pull out my press force meter from a box, I will definitely compare the two assemblies just for my own interest.

Finally today I had some lousy time and measured the two springs.

21.16 lbs for old spring vs 26.67 lbs the new.

And considerably harder to close the bolt. I lubed the metal to metal with PTFE oil.

Until Spring weather I won't visit my range to test.

21.16 lbs for old spring vs 26.67 lbs the new.

And considerably harder to close the bolt. I lubed the metal to metal with PTFE oil.

Until Spring weather I won't visit my range to test.

With an old spring closing the bolt was not really easy.

With a new spring now it is even harder. The gun sitting on rest and shooting from a Bench this is not really a convenient.

Not seeing any tricks how could I make that bolt easier to handle?

With a new spring now it is even harder. The gun sitting on rest and shooting from a Bench this is not really a convenient.

Not seeing any tricks how could I make that bolt easier to handle?

You can have an experienced 'smith' adjust the amount of 'c o c k on closing" and reduce how firmly the 'notch' holds the cocking piece in place.

This requires grinding on the cocking piece and on the rear of the bolt and this alteration also affects the trigger in that future triggers may require re-fitting.

This requires grinding on the cocking piece and on the rear of the bolt and this alteration also affects the trigger in that future triggers may require re-fitting.

Last edited:

Adjust....meaning machining the closing slot either on bolt or the action pocket?You can have an experienced 'smith' adjust the amount of 'c o c k on closing" and reduce how firmly the 'notch' holds the cocking piece in place.

A closer look with a high power jewellers loupe and I see some slight seizing marks on the "head" if I can call it in that way from my non educated language ...

My mind is telling me that would be better to disassemble the barrel from the action?

Nothing to do with the barrel and action...Adjust....meaning machining the closing slot either on bolt or the action pocket?

A closer look with a high power jewellers loupe and I see some slight seizing marks on the "head" if I can call it in that way from my non educated language ...

My mind is telling me that would be better to disassemble the barrel from the action?

This requires grinding on the cocking piece and on the rear of the bolt and this alteration also affects the trigger in that future triggers may require re-fitting.