That would work as well.Just found this thread, great idea for using the comparator.

Rather than an o-ring to fill the space I drilled down into the red holder section with a .250 drill bit.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rim thickness gauge.

- Thread starter fugemall

- Start date

If you have a chronograph, see if your sorting translates into better velocity groupings as compared to a random box.

I have to say I was shocked when I chronoed 30 rounds of Lapua Long Range. ES of 20, SD of 5.6. Props to Lapua.

Compared to 20 rounds of SK Long Range Match. ES of 51, SD of 10.9

I have to say I was shocked when I chronoed 30 rounds of Lapua Long Range. ES of 20, SD of 5.6. Props to Lapua.

Compared to 20 rounds of SK Long Range Match. ES of 51, SD of 10.9

Muzzle velocity isn't the only thing that might see a change due to sorting. The intended goal of rim thickness sorting is to try to bring more consistency to the ignition of the priming compound by narrowing the variance of the energy imparted by the firing pin. Better ignition can affect things other than muzzle velocity, and doesn't necessarily have to change the muzzle velocity outcome to have an overall effect.If you have a chronograph, see if your sorting translates into better velocity groupings as compared to a random box.

I have to say I was shocked when I chronoed 30 rounds of Lapua Long Range. ES of 20, SD of 5.6. Props to Lapua.

Compared to 20 rounds of SK Long Range Match. ES of 51, SD of 10.9

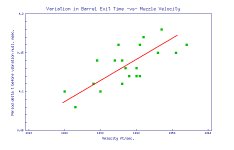

Here are 20 shots with their muzzle velocity graphed versus their muzzle exit timing relative to a certain portion of the vibration cycle. (Source: Geoffrey Kolbe) As you can see, there are several instances where shots with the same muzzle velocity had different muzzle exit delays. There are a few sources that can play a part in causing this variance. One of them is primer ignition, another is primer amount, and primer homogeneity. Powder ignition is affected by all those things. Powder burning behaviour is affected by that, and powder amount, and powder homogeneity, and bullet crimp pressure, and bullet-to-bore fitment (bore consistencty), and bullet lube type, and bullet lube amount, and bullet lube homogeneity. Variance in all of these things affects the amount of acceleration from one moment in time to the next. And that difference in acceleration is what's responsible for the variance we see in the bullet exit timing versus the muzzle velocity.

A bullet having a given muzzle velocity can experience a variety of differing acceleration from moment to moment to get to that velocity. And all of those variables play a part in the amount of acceleration the bullet is experiencing at any given moment. This is one of the reasons why two bullets with exactly the same muzzle velocity may not go through the same hole. Barrels are not static things. They are moving/vibrating once the firing cycle begins. So the timing of bullet exit plays a huge role in the ultimate launch angle. Change the exit timing, change the launch angle. How quickly the barrel is moving/vibrating determines how big of a change in launch angle there might be. If you want all shots to go through the same hole you need them all to have the same muzzle velocity and same launch angle, among other things, which also means the same exit timing. Having a consistent muzzle velocity is indeed important, but it is not the sole factor that determines how precise things will be within a group of shots.

Sorting by rim thickness can reduce variance in primer ignition. That has a knock-on effect for the remainder of the burning cycle. It does so by reducing the variance in energy received from the firing pin. If the firing pin is having to crush a varying amount of brass from shot to shot then that will introduce more shot variance than if it is having to crush a more consistent amount of brass from shot to shot.

Sorting by weight can reduce variance in all the various components, even when "You don't know what you're weighing." Experience disassembling way too many rounds than anyone ever should has shown me that the vast majority of the weight difference is just in the bullet itself. This doesn't change the fact that the brass contributes to the weight difference, and so does the primer compound, and so does the powder, and so does the bullet lube. But most of the difference is still due to that bullet, in large part simply because the bullet is also the heaviest thing. No, when you have two rounds that both weigh 51.2 grains you do not know if all of the brass is the same weight, or primer compound, or powder, or bullet, this is true. But it is also more likely that two rounds that weigh 51.2 grains will be more alike than a round that weighs 50.7 grains and one that weighs 51.9 grains. Take 5000 rounds of unsorted ammo from one lot number that vary between 50 and 53 grains and you'll have more variance on target than you will with 5000 rounds that all weigh 51.2 grains from the same lot number. You still won't know what you're weighing, sure, but you will have less variance in those rounds, and consequently you will also have less variance on target. Reducing variance in bullet weight will reduce variance in acceleration and muzzle velocity.

None of which negates the fact that the effect on results is still going to be smaller than what you get from simply buying better ammo, especially when matched to your rifle's behaviour. More consistent ammo isn't just about more consistent muzzle velocity. It is also about more consistent exit timing. More consistency in both of those things is required for better performance on target. More consistent muzzle velocity doesn't help all that much if you still have too much variance in launch angle due to exit timing variance.

Last edited:

I produce a 3d printed gauge that does a great job and has proven it self worth while. I have found it to be the cheapest way to squeeze extra accuracy out of cheap ammo. If your interested I can send you more info or even printable files.

I tried what you are doing long time ago.....

Sort cci std v by rim weight and then by rim thickness. Find a window of both and eliminate the outliers. Was doing it as a push back to european ammo never being in stock.

The weight sorting was in theory to measure powder charge, but after observation I feel that the weight difference is tied more to extra rim thickness (brass material) then powder charge.

To get rid of fliers and tighten group by about 15% I was having to get rid of half of the ammo.

It was taking me hours and would stress me out the night before a match if I had to sort.

IMHO just shoot cci stdv as is, knowing there will be fliers and a bigger group.

Got to pay to play, find a lot of sk, rws or elly that works and get a case (5000) for a seasons of ORPS or NRL 22. Then forget about ammo and work on shooting.

Spend your time practicing or dry firing instead of sorting poop..

Sort cci std v by rim weight and then by rim thickness. Find a window of both and eliminate the outliers. Was doing it as a push back to european ammo never being in stock.

The weight sorting was in theory to measure powder charge, but after observation I feel that the weight difference is tied more to extra rim thickness (brass material) then powder charge.

To get rid of fliers and tighten group by about 15% I was having to get rid of half of the ammo.

It was taking me hours and would stress me out the night before a match if I had to sort.

IMHO just shoot cci stdv as is, knowing there will be fliers and a bigger group.

Got to pay to play, find a lot of sk, rws or elly that works and get a case (5000) for a seasons of ORPS or NRL 22. Then forget about ammo and work on shooting.

Spend your time practicing or dry firing instead of sorting poop..

I hope to demonstrate this tmrw. I have a great solid load with 69gr SMK using one SSC powder, and have made test loads using a coarser stick powder in the same velocity range.….More consistent ammo isn't just about more consistent muzzle velocity. It is also about more consistent exit timing. More consistency in both of those things is required for better performance on target. More consistent muzzle velocity doesn't help all that much if you still have too much variance in launch angle due to exit timing variance.

looking forward to whatever I will see.

I'm interested to see what you've designed, just out of curiosity. I think the walls of my house have a coating of PLA.I produce a 3d printed gauge that does a great job and has proven it self worth while. I have found it to be the cheapest way to squeeze extra accuracy out of cheap ammo. If your interested I can send you more info or even printable files.