So far the focus on spring tuning has been on replacing the recoil spring with a different weight. Only thing I'll add to spring tuning (to slow down a slide) is to try a "square bottom or small radius" Firing Pin Stop. I haven't personally tried it but there are lots of posts in different forums that praise its benefits.

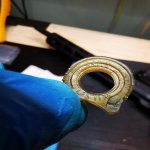

For example, without using a higher than standard power spring, say from 16 to 18 lbs/in spring (which will result in #1 answer above), a smaller radius or square bottom firing pin stop will slow down the rearward movement of the slide. This is an almost latent feature of the firing pin stop, which is the ability to tune or adjust slide velocity. The radius, or lack of it, slows down the slide because the square bottom will have less leverage to push back the hammer to #### it. John Moses Browning of course knew this.