I won't be buying that thing because of the name, ha!i was thinking about the “crypto” might have to rethink that… i like what i see sofar!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sterling Arms R18 MK3

- Thread starter Horilka

- Start date

mmcintyre1220

CGN frequent flyer

- Location

- Tillsonburg, Ontario

Whatever IRG has been putting together has been in the making for 4 years. I have a feeling it won't be out until atleast next year AND the price is going to be high for what it is. Just a feeling, no info to support it.. IRG-PSA JAKL, WK-180 Gen 3.

Looks like I got a Kodiak interview mixed up with a Sterling interview. After reviewing the interview, their are differences like the bolt release and metal type that will prevent the Mk3 upper from fitting a Mark 2 lower, my bad. JR did say they can't skew too much away from the MK design, as some commonality is needed to use the existing FRT.

Minor, incremental improvement to an existing design is certainly permitted, the SAI R18 Mk3's new NR FRT entry being a case in point. Provided that the basic operating system remains Short-Stroke Piston, with a Bolt Carrier riding on dual Guide Rods with dual Operating Springs, the AR180B lineage is recognizable. Cosmetic changes to a firearm's appearance (eg. the angle of the Magazine Well's bottom edge), are not sufficient to garner a rejection. So long as the firearm's lineage is identifiable and the new version does not stray too far from the source material (eg. the same operating system), then an update ought to receive RCMP Lab approval. Of course there are implications associated with the coming into force of Bill C21 which must also be taken fully into account when designing a new or updated firearm for the (now unique) Canadian market.

In other news, I will be receiving my Mk3 pre-production Test Rifle in 2 days time, this Thursday afternoon. You can expect my Part 1 "Initial Impressions" Review to land here on CGN a few days after that.....

Last edited:

DaveMachine

CGN Ultra frequent flyer

- Location

- That one place with a cowboy complex

You mind running some 75-77gr match ammo through it? I wouldn't mind sending something I have on hand or making a small donation to the ammo fund.

Would you be able to include some maintenance tips/upkeep for it (specifically regarding the updated piston system)? I bought a mk2 and being new to firearms in general, most of my issues were from maintenance items that weren't included in the original manual (i.e. soak the **** out of your gas block in CLP every couple hundred rounds).

You mind running some 75-77gr match ammo through it? I wouldn't mind sending something I have on hand or making a small donation to the ammo fund.

I don't mind, after all it is not my rifle (yet)! Just kidding - If you provide factory match ammo, I will certainly do my utmost to properly group it for all to see. I believe that SAI is going to provide some bulk ammo for accuracy and reliability testing purposes, so there ought not be much of a need for an "ammo fund" this time around. I won't have an opportunity to fire the rifle immediately, so Part 2 of my Review (Accuracy and Reliability Testing) may have to wait until a few weeks after Part 1.

Would you be able to include some maintenance tips/upkeep for it (specifically regarding the updated piston system)? I bought a mk2 and being new to firearms in general, most of my issues were from maintenance items that weren't included in the original manual (i.e. soak the **** out of your gas block in CLP every couple hundred rounds).

I will consider adding a few specific tips to the post-firing component of my Accuracy and Reliability Testing Report, which will follow a few weeks after I publish my Part 1 - Initial Impressions of the R18 Mk3. Firearms maintenance is kind of a personal thing, in that everyone has their own method/sequence for cleaning, their own shortcuts/tips/tricks, and so on. That said, there are some specific things that should be paid attention to, and I will try to mention those in my Live Firing Report.

How does the steel carrier ride in Mk3 (or in Mk2) aluminum receiver? I suppose just on aluminum rails?In other news, I will be receiving my Mk3 pre-production Test Rifle in 2 days time, this Thursday afternoon. You can expect my Part 1 "Initial Impressions" Review to land here on CGN a few days after that.....

I don't recall any steel insert for rails. It would be visible on the sides of the upper as they usually have screws or some plate to keep it fixed in the aluminum.How does the steel carrier ride in Mk3 (or in Mk2) aluminum receiver? I suppose just on aluminum rails?

,How does the steel carrier ride in Mk3 (or in Mk2) aluminum receiver? I suppose just on aluminum rails?

No, you suppose wrong. The AR180B operating system is nothing like that of the CZ Bren 2, where the Bolt-Carrier rides on Receiver Rails. On the 180B and therefore the R18 Mk2 and Mk3, the Bolt-Carrier rides on 2 Guide Rods which also contain the Operating Springs (located behind the Carrier). The Operating Springs force the Bolt-Carrier forwards on the Guide Rods to feed a fresh cartridge and lock the breech after the Short-Stroke Gas System has forced the Bolt-Carrier and Bolt to the rear, ejecting the empty cartridge and cycling the action.

On the R18 Mk2, the Operating Springs were loose on the Guide Rod, sandwiched in place by the Rear wall of the Receiver and the Bolt-Carrier. On the Mk3, the greatly-reduced Bolt-Carrier and Springs are captive on the Guide Rods, forming a unitized assembly that closely resembles the (non-patented) SIG MCX internal operating system. If you watch the "Ballistically Speaking" TACCOM interview with JR Cox, owner/operator of "The Shooting Edge" retail store and indoor range in Calgary, as well as Rangeview Sports in Gormley, ON, the Mk3 operating system is discussed near the end of the show when the disasssembled rifle is introduced JR is the principal designer of the R18 Mks 2 and 3, with manufacturing and international sales managed by Sterling Arms International out of the UK.

I will have detailed photographs of the disassembled Mk3 when I receive a Test Rifle in 2 day's time. Expect to see Part 1 of my Review (Initial Impressions) within the next week.

Guide rods do not eliminate rails, they are mostly to guide springs, not carrier. Here's original AR180B design, it has rails. Try this - remove guide rods with spring and drop carrier into upper receiver. It should either slide forward and back on some kind of rails (most likely) or rattle in all direction (very unlikely). I saw the video you mentioned, I can't see how carrier is guided inside.

Regardless of design and used materials, take a note if there is wear after you finish testing rifle.

Regardless of design and used materials, take a note if there is wear after you finish testing rifle.

Last edited:

If you had some point to fix and hold front of the guides and if the guides were extending much further forward like MCX, you could possibly hang the carrier and move it on guides without touching walls. But it is clearly no the case with mk3, it appears to me that there is contact between carrier and upper walls.

There won't be any wear on the sides, top or bottom of the Bolt Carrier of the interior walls of the Upper Receiver because the two parts do not contact each other. The Bolt Carrier rides on the Guide Rods, not on some imaginary Receiver Rail.Guide rods do not eliminate rails, they are mostly to guide springs, not carrier. Here's original AR180B design, it has rails. Try this - remove guide rods with spring and drop carrier into upper receiver. It should either slide forward and back on some kind of rails (most likely) or rattle in all direction (very unlikely). I saw the video you mentioned, I can't see how carrier is guided inside.

Regardless of design and used materials, take a note if there is wear after you finish testing rifle.

View attachment 817474

Do you even have an original AR180? Because I do , and am looking at mine as we speak. Those "rails" you have circled are simply longitudinal ribs to both strengthen the Receiver wall and to give a place for dirt and fouling to accumulate. They have nothing whatsoever to do with guiding the Bolt Carrier. I can assure you that if I drop the Bolt Carrier into the Receiver without the Guide Rods, the Bolt will rattle all the way forwards. You need to listen and not automatically reject what you are told by those with the inside scoop on the details....

Here is a photo of the SIG MCX's unitized Bolt, Bolt Carrier, Operating Springs and Guide Rods. This is the same basic design followed by the Mk3's heavily-revised internals.

Last edited:

See my above post. If I am wrong and the Mk3 Bolt Carrier is fully guided by Bolt Carrier contact with the interior Upper Receiver walls, then I will be the first to admit it. However, that would represent a genuine change from the AR180 design, wherein the use of Steel Guide Rods avoided the need for machining of the Bolt Carrier's external surfaces and the interor walls, bottom and inside top of the Upper Receiver. The machining wasn't necessary because there was no physical contact between the Bolt Carrier and the Upper Receiver walls. The Guide Rods did exactly that - they guided the Bolt Carrier's movement within the Upper Receiver.If you had some point to fix and hold front of the guides and if the guides were extending much further forward like MCX, you could possibly hang the carrier and move it on guides without touching walls. But it is clearly no the case with mk3, it appears to me that there is contact between carrier and upper walls.

MCX rods are supported in front and the carrier hands on the rods

It apears that MK3 has only rear half of this arrangement and I'm not sure how you can suspend carrier on MK3 rods while it is moving back, the front T ends of the rods should hang free. But only looked at it for a moment in person.

It apears that MK3 has only rear half of this arrangement and I'm not sure how you can suspend carrier on MK3 rods while it is moving back, the front T ends of the rods should hang free. But only looked at it for a moment in person.

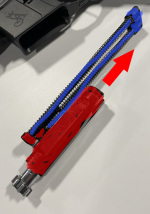

Parts in red should recoil back, blue should stay. So once you are going back the rods will stay, but they have no support in front and no part to hold them. Is it not?

The Guide Rods and Springs on the MCX are supported at the Front and Rear by the shape of the forged Upper Receiver, which narrows below the Guide Rods/Springs, providing a dedicated channel for them to reciprocate within.

Note that the SIG MCX uses a different concept than the R18 for its Bolt Carrier and Upper Receiver relationship. On the MCX the body of the Bolt Carrier is indeed guided by the curved walls of the Upper Receiver, just like an AR15 Bolt Carrier riding within the tubular walls of an AR Upper Receiver. The AR180 and by extension the R18 MK2 Bolt Carrier (a square block) is not guided by the Upper Receiver walls. The Carrier rides on those 2 Steel Guide Rods, and the Bolt Carrier does not contact the Receiver walls while moving back and forth during the operating cycle.

Note how in the photo below, the AR180 Upper Receiver walls do not conform to the shape of the Bolt Carrier, which instead rides on the Steel Guide Rods as opposed to any sort of rail or the Receiver walls themselves. Also note the empty space between the Bolt Carrier and the Upper Receiver walls. Once again, on the AR180 the Bolt Carrier does NOT make contact with the Upper Receiver until it is closed and locked against the Barrel Trunnion.

I believe that the R18 Mk3 still follows the AR180 design wherein the Guide Rod principally guides the Bolt Carrier within the Upper Receiver. The Bolt Carrier does not ride on an internal Upper Receiver Rail, nor does it bear against the Receiver walls themselves. I will be able to confirm this when I receive the pre-production Test Rifle on Thursday afternoon.

Last edited:

Yes, please do. You guessed right, I was trying to understand mk3 by looking at online videos - not the best source of information, because I don't own AR180B, nor do I have MCX. I am indeed curious how it is done in Mk3. As owlowl pointed out - for carrier to ride only on guide rods, they should be fixed in place at rear and front, like on MCX. From Mk3 pictures it doesn't look like they are supported in front. Looking forward for your initial impressions on the rifle, Mark.. I will be able to confirm this when I receive the pre-production Test Rifle on Thursday afternoon.