Holy #### Todd!!!

I really F'ed up, I didn't see my typo!!

I am so sorry , I'm loading 80 grains, what a screw up.

Hah! Well better a typo on cgn than in your reloading notebook!

Holy #### Todd!!!

I really F'ed up, I didn't see my typo!!

I am so sorry , I'm loading 80 grains, what a screw up.

8 more , Speer 180sp.

3.472” And 3.472” the Last 6 were 3.475” to 3.477”.

Apart come the dies , again , see if I can drill the seater out at bit at the point.

to rule out your press, put a dial indicator on the ram in top position. Check for repeatability with and without bullet.

You can also put dial indicator on the die, see if the die moves when seating the bullet.

I think most likely its the seating stem. Maybe drill out the centre of the stem or invest in a competition seating die.

Seems way better no?

I would guess the relation between the bullet shape/tip vs seating stem is the problem...

2-3-4 thou between std bullets seems reasonable to me... and way better than your long bullets...

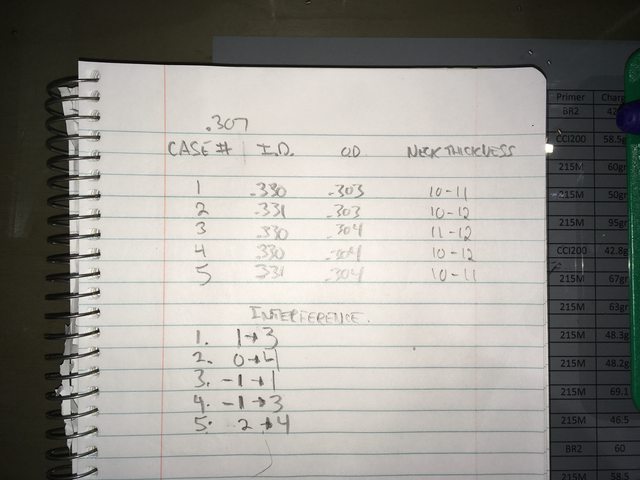

I would guess ... too much neck tension.

If you have a way to adjust the neck sizing, go with a net 1 to 1.5 thou squeeze after it comes out of the sizing die.

If the sized brass has upwards of 3 to 5 thou neck tension, that is likely the problem... plus runout may not be ideal either.

Finally, you may have donuts at the base of the case neck which affects the depth the bullet can travel in. Expand with a mandrel and outside neck turn.

If the brass has been fired a few times, anneal the case necks as well.

sounds like a neck tension issue.....

Jerry

Kelly a couple thoughts here. Incase I missed it, did you pull your seater stem and drop a bullet in? With basic Lee seaters anything with a high BC contacts the stem too high up the bullet where inconsistencies in the bullet greatly affect seating depth. Even when measuring BTO. I switched my 308 to a Forster BR seater rather than send bullets to Lee for a custom stem. This almost solved the issue for me. Which brings me to thought number two. My press is a Lee Breechlock Challenger and with the Forster BR die set up according to the instructions (mainly, backed out so that the shell holder does not touch the die at the top of the stroke) I still had variations in seating depth. I found that by varying pressure on the press handle affected seating depth by over 5 thou. The linkage had enough flex in it's topout stops to make seating depth as well as shoulder setback an inconsistent affair. Readjusting my BR seater to just lightly kiss the shell holder solved the issue and bullets were seating to within the .0005" claimed resolution of my crappy tire calipers every time. Also, I tried drilling a Lee seater but ended up giving up on it and learned that the Forster seated right off the ogive so was opened right up to nearly bullet diameter. I suspect opening your seater that far, if possible, and ensuring you are not experiencing any press linkage flex on top out will eliminate this issue as it did for me. Sorry, I missed which press and dies you are using but hopefully this can help you out.

Dear Mr Kelly, I have suffered from the same thing for years. I found some useful tips to try in this thread. I’m pretty sure it’s my equipment because this issue of mine spans several different caliber s and bullets. I have spent many hours banging my head on the table trying to find consistency.... I feel your pain lol.

Measure off the ogive instead of COAL. see if that makes a difference. But, it's not uncommon amongst bullet manufacturers to throw bullets off different production lines where different dies are making bullets into one lot, instead of keeping one lot together off of one production line.

You already have shown that the length of the bullets is within your acceptable range. Try measuring the bullets alone in your seating stem. Ensure you keep the bullets in the same relative alignment to the stem by perhaps laying them in a “v” block and measuring OAL of stem and bullet. When you have sorted them into batch’s load a similar batch and check for cartridge OAL.