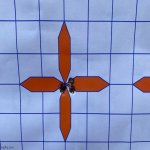

I just developed a load for a 300WM that was putting shot after shot into the same ragged hole.

I used 1F RP brass from factory ammo for my test loads, and didn't bump the shoulders back. They chambered fine, and no signs of pressure right up to max in my test loads.

I always use 0F RP brass for my hunting loads. My 0F brass is .016 to .018 different on my headspace gauge from the test loads.

Would this affect POI to any degree? Or would the near instantaneous case swell upon firing negate any pressure change?

Before I load up a pile of rounds with my most accurate load for hunting season, I'd like to hear your thoughts.

Of course, I'll be hitting the range again just to be sure (even though my test loads ended up dead on the bullseye). Thanks!

I used 1F RP brass from factory ammo for my test loads, and didn't bump the shoulders back. They chambered fine, and no signs of pressure right up to max in my test loads.

I always use 0F RP brass for my hunting loads. My 0F brass is .016 to .018 different on my headspace gauge from the test loads.

Would this affect POI to any degree? Or would the near instantaneous case swell upon firing negate any pressure change?

Before I load up a pile of rounds with my most accurate load for hunting season, I'd like to hear your thoughts.

Of course, I'll be hitting the range again just to be sure (even though my test loads ended up dead on the bullseye). Thanks!