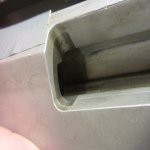

Someone previously true the lugs on the bolt/action and get carried away?

This is certainly a possibility and gets my vote....it would be nice to know the history of the firearm and if it is the product of DIY or a Factory QC issue.

Someone previously true the lugs on the bolt/action and get carried away?

Someone previously true the lugs on the bolt/action and get carried away?

No..........

This is certainly a possibility and gets my vote....it would be nice to know the history of the firearm and if it is the product of DIY or a Factory QC issue.

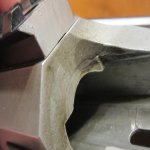

If you are the original owner that might be an option but at this stage it isn't worth the effort.

Nice work guys.

I've never used "sheet" type silver solder. Never heard of it until now.

I have had a 'roll' of it since 1970... it started out about 10 feet long and is an inch across and about 7 thou thick. I have 6 feet of it left. A little goes a long way.