Rick you seem intent on proving headspace in straight wall rimless cases somehow doesn’t rely on the case mouth being prominently and squarely available to rest upon the front of the chamber and headspace the cartridge. It doesn’t take a long post to explain that it certainly does.

Right back at ya: You seem determined to convince people there is no way that a roll crimped pistol cartridge can properly headspace in a pistol - but on the other hand a taper crimp does. Or in a rifle if you prefer to narrow it down to that.

What makes you so certain that a) everybody trims every single one of their straight walled cases to exactly the same length? And b), if you actually do that, whatever your chosen length, when you chamber your reloads (no matter what kind of crimp you applied, if any) that in fact "the case mouth is prominently and squarely resting upon the front of the chamber" to headspace the cartridge?

It would be magical if every single chamber cut for straight walled cartridges measured exactly the same distance from the back to the front edge of each and every chamber. No differences whether the chambering reamer was new or worn, no differences from variations from barrel to barrel in the chambering machinery. Exactly the same - so all you have to do to get headspacing right is trim all your cases to the length specified in your reloading manual to get that case mouth/chamber edge contact for headspacing.

Nothing personal, but if you want to cling to that belief without bothering to even try the alternative, if that works for you, I am never going to tell you that you must stop doing that. Nor am I going to order you to break out a borescope and confirm that all your straight walled cases, however they're crimped, are in fact firmly seated against the forward edge of the chamber in order to be properly headspaced.

If you do in fact have a look and discover that they are short of the front edge of the chamber, what then?

How many reloaders of straight walled cases ensure that all their cases are trimmed to be the specified maximum trim to length for the cartridge to ensure the case mouth is properly butting against the front edge of the chamber for proper headspacing with every single round?

What if there is .003" +/- variation of that individual reloaders' trimmed cases from specified trim to length because few actually bother ensuring all their cases are the same length to a thou or two?

And what if SAAMI tells you to trim your cases .010" SHORT of the maximum case length? Assuming your chamber is precisely cut to SAAMI spec, when you start with cases that are already .010+" short of touching the front edge of the chamber, there's more variation than what you want to believe exists between a taper crimp, roll crimp, Lee Factory Crimp, etc.

In other words, whether you crimp or not, SAAMI's guidance to the publishers of reloading manuals is to have you trim your brass so that it is well short of ever touching the front edge of the chamber.

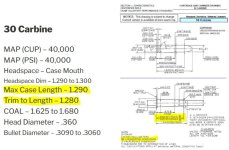

Maximum headspace dimension: 1.300"

Minimum headspace dimension: 1.290"

Trim to length dimension: 1.280"

In the old math, that's .020" shorter than a maximum chamber, .010" short of a minimum chamber.

You see any contact between the case mouth and the front edge of the chamber to obtain consistent headspacing in those dimensions?

When we start also stake crimping and asphalting bullets for civilian use because the crimp we choose to use when reloading .30 Carbine isn't sufficient, then pointing us at the .30 Carbine might be a bit persuasive. For now it is merely instructive in how following trim to length specifications from SAAMI leave your case mouth well short of contacting the front edge of the chamber for precise headspacing.