It won't do much with cupro-nickel, it's much harder than most copper alloys or lead.I’ve found the Big 45 metal cleaner works amazing on really bad bores. It looks like a steel put scrubber except it’s a soft alloy, wrap a little around a bore brush and maybe 10 passes through might remove the raised deposits.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

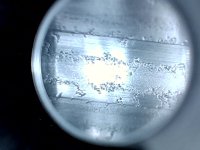

What kind of fouling is this mess?

- Thread starter Hitzy

- Start date

I've tried it without much success. I believe its general purpose was as a lubricant, rust inhibitor, and to nullify corrosive primer issues.Maybe some Swiss Waffenfett grease would do the trick, I think that's all they used with the K31's and they only saw cupro-nickle projectiles.

Rarely come across a K31 with a fouled up mess of a bore like this Dane M58 lol.

If I can't scrub it out, I'll send it to one of you guys with the electrode set up, I'm not that committed to building one lol.

Soaking it with some carb-out, see if that does anything, then I'll wrap a bit of chore boy around a brush and do some JB scrubbing, I'll try the blue with some kroil, see if that works a bit faster then the red.

The Swiss had, and still have stringent cleaning regimens.

Every nation in the world used cupro-nickel jackets for military bullets at one point. They all went away from them for the same reasons.

Cupro-nickel isn't a real issue if it's taken care of properly.

Don't worry too much about JB pore base making the patches black. They'll always come out that way. I've tried them on unused barrel blanks and they come out looking the same. As long as you are making progress I'd keep going.

Chris.

Chris.

The JB Blue did some work, never tried it, was still new in the wrap.

Instructions say oil the bore, then do the JB patch over a brush 20 strokes, red says 100 strokes, so obviously a little finer and milder.

Only did one go, super messy with the oil, the patch disintegrated lol. Took a bunch of dry patches just to get it cleaned out after.

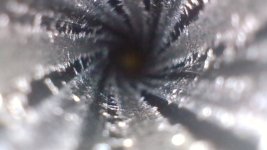

Lands are coming along now, grooves are still ugly but it's going to come clean I'm sure now.

Instructions say oil the bore, then do the JB patch over a brush 20 strokes, red says 100 strokes, so obviously a little finer and milder.

Only did one go, super messy with the oil, the patch disintegrated lol. Took a bunch of dry patches just to get it cleaned out after.

Lands are coming along now, grooves are still ugly but it's going to come clean I'm sure now.

Attachments

Have one of the Outers units. Works well when needed. - dan

Yeah, crown is good, I shot it several years ago with some hand loads, but only 20 rounds, was ringing the 6" gong at 100m steady which is about the extent of my eyes these days so i considered it accurate lol.Hate to say it, but that looks like pitting. Unpitted areas are getting shiny. I'd just shoot it and expect it will take a bit more cleaning because the pitting will pick up fouling.

Nice sharp crown?

Still scrubbing, using a slightly tighter brush, getting lots of stuff out of the grooves now.

The first 1/3 and last 1/3 of the bore are the worst, the middle is cleaning up decent.

Tried the bore scope without the mirror to see if it was pitting or fouling still raised, it's still raised alot, can't tell with the side view as well.

About to throw the bore scope in the trash though, this is way more scrubbing then I bargained for lol.

Plus the app is giving me pop up adds blocking the view and pictures every 10 seconds now, teslong bore scope, pain in the ass more then it's useful lol.

OP,

Lubricate the bore w/ bore solvent- MC7 Shooter's Choice.

Balistol is useless schit.

With a bore guide & 1 size larger bore brush attached to an over length cleaning rod.

Chuck the cleaning rod in a cordless drill.

Run on slow speed & feed thru the bore.

Reversing the process back to the chamber.

Make 2-3 passes.

Clean the carbon out w/ 3-4 wet solvent soaked patches followed by a dry patch.

No rod damage or tennis elbow issues.

A chamber brush of larger diameter will clean the chamber in the same manner.

Lubricate the bore w/ bore solvent- MC7 Shooter's Choice.

Balistol is useless schit.

With a bore guide & 1 size larger bore brush attached to an over length cleaning rod.

Chuck the cleaning rod in a cordless drill.

Run on slow speed & feed thru the bore.

Reversing the process back to the chamber.

Make 2-3 passes.

Clean the carbon out w/ 3-4 wet solvent soaked patches followed by a dry patch.

No rod damage or tennis elbow issues.

A chamber brush of larger diameter will clean the chamber in the same manner.

Agreed.I hate the thought of anything spinning crap in a rifled barrel... working on the sharp edges of the grooves... I wouldn't do it to anything I owned.

maple_leaf_eh

CGN Ultra frequent flyer

Do the sights look like this?This is in an.old S&L M58 target rifle in 6.5x55, those ones built on K98 receivers, Garand type sights, cut down K98 stock, finally getting around to cleaning it up after way too many years sitting in the safe.

https://www.canadiangunnutz.com/for...8-otterup-ejector-and-bolt-stop-help.2112659/

I like it, even if the bore is crusty.

Looks like pitting and the polished Smooth part looks like lead. I have bores that look like this that pretty much stay that way no matter what I do, although mostly they shoot ok. Also a pitted bore you can never get all the carbon out, there is always more hidingThe JB Blue did some work, never tried it, was still new in the wrap.

Instructions say oil the bore, then do the JB patch over a brush 20 strokes, red says 100 strokes, so obviously a little finer and milder.

Only did one go, super messy with the oil, the patch disintegrated lol. Took a bunch of dry patches just to get it cleaned out after.

Lands are coming along now, grooves are still ugly but it's going to come clean I'm sure now.

No drill, just the JB on a patch over a brush.Those last pics look odd to me. How are you scrubbing? That stuff hanging radially really looks odd. Did you do the cordless drill thing?

The bore scope focus is pretty narrow with the mirror removed, but yeah, it's like stalagmites or something.

Doesn't the brush rotate and follow the rifling?No drill, just the JB on a patch over a brush.

The bore scope focus is pretty narrow with the mirror removed, but yeah, it's like stalagmites or something.

With it looking like that I'd take a naked bronze brush and scrub it with some solvent, maybe even a little of the JB in it, making sure the brush is tight enough and chasing the rifling....

Then I'm thinking I'd shoot a few cup-n-core bullets through it to get some copper fouling and see how that cleans. Might show a little more of what's going on....Doesn't the brush rotate and follow the rifling?

With it looking like that I'd take a naked bronze brush and scrub it with some solvent, maybe even a little of the JB in it, making sure the brush is tight enough and chasing the rifling....

With the amount of fouling I see in those pics, I would be using something much more aggressive than JB's.

How to clean cupro-nickel fouling: Cleansing-compositions.-A liquid for removing cupro-nickel fouling from rifle barrels consists of potassium bi-chromate and chromic anhydride dissolved in water.

-----------------------------------------------------------------------------------------------------------

This was one of Townsend Whelan's cleaners, it is highly recommended to use this solution outdoors or have some sort of mechanical ventilation.

JB's isn't hard enough to remove the nickel.

Ammonia, only dissolves the copper, appx 75% but leaves the nickel, appx 25%, bonded to the steel of the barrel.

You're very lucky, there wasn't rust in that bore.

One of the things I often see stated from back in the day, when cupronickel fouling is left in the bore, rust almost always accompanies it, because of the electrolytic reaction of the three metals, with any moisture, including airborne.

I've used the above solution. I don't remember the exact mix ratio, but 50-50 rings a bell. BE CAREFUL if you go this route. It will dissolve plastic, finish on wood, and skin.

How to clean cupro-nickel fouling: Cleansing-compositions.-A liquid for removing cupro-nickel fouling from rifle barrels consists of potassium bi-chromate and chromic anhydride dissolved in water.

-----------------------------------------------------------------------------------------------------------

This was one of Townsend Whelan's cleaners, it is highly recommended to use this solution outdoors or have some sort of mechanical ventilation.

JB's isn't hard enough to remove the nickel.

Ammonia, only dissolves the copper, appx 75% but leaves the nickel, appx 25%, bonded to the steel of the barrel.

You're very lucky, there wasn't rust in that bore.

One of the things I often see stated from back in the day, when cupronickel fouling is left in the bore, rust almost always accompanies it, because of the electrolytic reaction of the three metals, with any moisture, including airborne.

I've used the above solution. I don't remember the exact mix ratio, but 50-50 rings a bell. BE CAREFUL if you go this route. It will dissolve plastic, finish on wood, and skin.