Hi everyone! I just wanted to share my project. Hope this is the right spot.

I will say first things first, I spoke with the CFO at TACCOM and confirmed that 3d printing accessories/furniture is legal.

I've always loved the Spas12 from JP and Terminator. Then of course I found out we weren't allowed to own one. Years later my mind creative mind started putting this together over the last few months. I bought a Maverick 88, as I figured it looked close enough to the Spas12 and starting working on it. I used a program called Meshmixer and taught myself how to use it for this project. I modelled some parts and sent them off for printing. Of course they weren't even close to usable lol. I quickly realized I needed to invest in my own 3d printer to make this project affordable. Hundreds of $$$ later, I was able to change the design as required and print at will with PLA.

Eventually I've reached what I have now as seen in the photos.

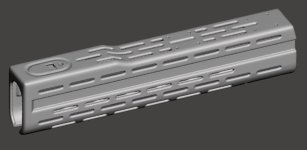

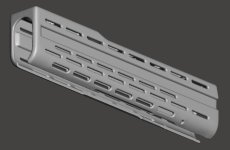

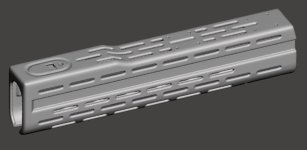

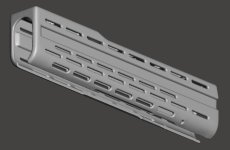

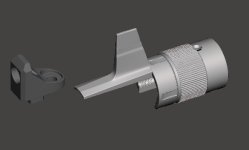

The heatshield is held onto the barrel with a clamp type system. I added a pad on the heatshield so that a aluminum block can be used to clamp the barrel, and insulate the polymer heatshield from the heat of the barrel.

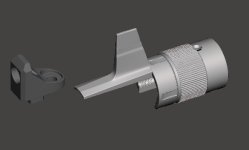

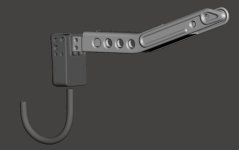

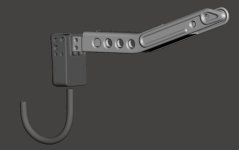

The foregrip mounts to a action slide. I designed it so that I can print just the action slide should it break/require a redesign.

I currently have nylon filament on the way to print what should be functional parts. I'm new to 3d printing and 3d design work, so I'm learning everything as I go, but feel like I've started to see my vision come together and wanted to share.

Let me know what you think.

I will say first things first, I spoke with the CFO at TACCOM and confirmed that 3d printing accessories/furniture is legal.

I've always loved the Spas12 from JP and Terminator. Then of course I found out we weren't allowed to own one. Years later my mind creative mind started putting this together over the last few months. I bought a Maverick 88, as I figured it looked close enough to the Spas12 and starting working on it. I used a program called Meshmixer and taught myself how to use it for this project. I modelled some parts and sent them off for printing. Of course they weren't even close to usable lol. I quickly realized I needed to invest in my own 3d printer to make this project affordable. Hundreds of $$$ later, I was able to change the design as required and print at will with PLA.

Eventually I've reached what I have now as seen in the photos.

The heatshield is held onto the barrel with a clamp type system. I added a pad on the heatshield so that a aluminum block can be used to clamp the barrel, and insulate the polymer heatshield from the heat of the barrel.

The foregrip mounts to a action slide. I designed it so that I can print just the action slide should it break/require a redesign.

I currently have nylon filament on the way to print what should be functional parts. I'm new to 3d printing and 3d design work, so I'm learning everything as I go, but feel like I've started to see my vision come together and wanted to share.

Let me know what you think.