tenringbound

CGN frequent flyer

- Location

- Atlantic Canada

Congrats on an amazing build! I honestly think you’d be sitting on a gold mine if you were able to produce these kits in quantity.

I really wonder why no aftermarket company that produces stocks has done a kit. I think it's probably getting a license to make Frenchi parts/Frenchi appearing parts, copyright infringement etc... maybe.Congrats on an amazing build! I honestly think you’d be sitting on a gold mine if you were able to produce these kits in quantity.

Amazing work!3d printed a Jurassic Park Raptor skull (supposedly life size) and T-rex skull because what better addition to a spas12 lol.

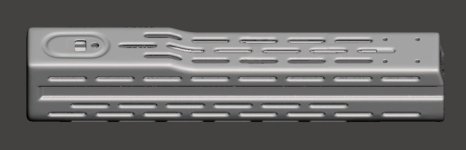

View attachment 850222View attachment 850223

Would love to buy the shotgun from ya and bring the parts in to a fab shop i know and see if they could make a full kit to sell later down the road to mav 88 owners!!!3d printed a Jurassic Park Raptor skull (supposedly life size) and T-rex skull because what better addition to a spas12 lol.

View attachment 850222View attachment 850223