- Location

- ON, North of GTA

This looks like a ploimer M-Lok rail. Why so tight in the first place?

The proper drill size is not bigger than the head but is actually the size of the threaded screw itself. The screws heads are in the slots but are below the bottom of the pic slots so cutting with a hacksaw blade would require cutting the pic base. If the screws heads were proud of the slots in the rail then mounting anything wouldn’t be possible.I drill the head off then grab stud with lines pliers and within tension it comes out easy.

Drill bit used is the next fractional size up from screw head Diameter.

Heads up, the rail is destroyed doing this.

Yiur screw heads are in the slots on the rail, you can use a hack saw blade and cut a slot for a screw driver.

Either way you should be able to get it on your own.

A gunsmith is generally not viable, People just assume there's a gun Smith 15 minutes away from everyone

Drilling the same diameter as the screw will not remove tge head to allow tge base to come off.The proper drill size is not bigger than the head but is actually the size of the threaded screw itself. The screws heads are in the slots but are below the bottom of the pic slots so cutting with a hacksaw blade would require cutting the pic base. If the screws heads were proud of the slots in the rail then mounting anything wouldn’t be possible.

but your advise did suck. You said to use a drill LARGER then the screw head and then somehow grabbing onto the "stud" with pliers? Do you mean doing this after you take the other screws and rail off and have a theaded portion sticking up out of your action?if you read the thread I suggested drilling the heads off in post #4 , guntech repeated what I suggested in post #9, I then repeated it again in post #14 as it is the best way to accomplish this small task.

Nah I'll pass on your game, Ive dealt with narcissistic people like you.but your advise did suck. You said to use a drill LARGER then the screw head and then somehow grabbing onto the "stud" with pliers? Do you mean doing this after you take the other screws and rail off and have a theaded portion sticking up out of your action?

Explain to the folks at home how using the clearance drill for the thread size wouldnt remove the head again?

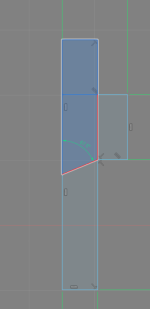

View attachment 799189

Perfect advice and even an avearge joe on a cordless drill free hand can pull this off...... Easy Peasy if you have a drill and a set of steel drill bits that are reasonably sharp.Now that the head is completely rounded out, start the drilling with a drill that fits in that hole just a short distance creating a center for the small drill (just a few thou over the thread diameter) to center on. When this drill reaches the screw thread, the head will pop off. The rail will not be damaged.

Buddy has sort of passed the point of no return with his rounded out head....I've had some success removing bubbad screws using an elastic band in the hole then inserting the tool.

Works somewhat OK removing rounded out Robertson wood screws

Wasn't trying to steal anyone's thunder.if you read the thread I suggested drilling the heads off in post #4 , guntech repeated what I suggested in post #9, I then repeated it again in post #14 as it is the best way to accomplish this small task.

Nah, just been attacked from people with zero to offer in terms of help but heaps of criticisms.Wasn't trying to steal anyone's thunder.