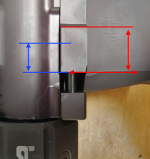

Aero managed to squeeze more metal into their enhanced upper than Colt does.

View attachment 816888View attachment 816889

All the recoil is transfered through the front of the little loop of aluminum. If you want to deactivate an AR in a hurry you open it and twist it apart. Takes a pair of hands and a knee. First one I did was an eye opener. The black/grey is a Colt upper.

View attachment 816890

Look at the block that transfers recoil.

View attachment 816891

The tolerances are tight enough that a .010" feeler gauge prevents the rear pin from going through the upper. I will admit that there is some machining blemishes and cosmetic ugliness. Sure to be a deal breaker to some and I hope it gets better after the initial production surge slows. I really don't care because the places I want perfect are. My IBI barrel fit perfect. No shimming or flange sealant required. Probably the tightest I have seen and same with the barrel nut threads. No slop with the Aero nut.

View attachment 816892

Crypto round hole.

View attachment 816893

You might not be able to make it out but ARs have a slightly elongated rear pin hole to accommodate multi manufacturer tolerances. This prevents the lug from transfering recoil. I remember USAR armourers bushing and reaming the two lugs chasing accuracy. Which would make them weaker but must have been strong enough.

Looking at the pins I am going to assume Crusader was not smoking crack and they go into the lower at minimum the same half inch they stick out. I would assume a press fit because that would work and be fast...and work.

View attachment 816898

The lower is not short on metal anywhere. There is no need to cheat and go a couple mm deep.

I have noticed the crusader is less sensitive to bipod placement than ARs are. I can only guess it is the lack of slop between upper and lower. Before I found getting the bipod back towards the magwell worked best for consistent POI. This Crypto doesn't seem to care. Pushed out front and bagged at the rear it works like a bolt gun.

I can't speak to the complete guns Crusader is selling, only to the spine.